Engine fuel supply system of motorcycle Yamaha YZF-R1 Y(C) (2009-2014)

See this section in russian language

Removing the fuel tank and fuel pump

Order Job/Parts to remove Quantity Remarks Rider seat Refer to " General chassis ". 1 Fuel tank side cover 2 2 Fuel tank upper cover 1 3 Fuel tank breather hose 1 Except for California Disconnect. 4 Fuel tank breather hose (hose joint to rollover...

Order Job/Parts to remove Quantity Remarks Rider seat Refer to " General chassis ". 1 Fuel tank side cover 2 2 Fuel tank upper cover 1 3 Fuel tank breather hose 1 Except for California Disconnect. 4 Fuel tank breather hose (hose joint to rollover...

Removing the fuel tank side covers

The following procedure applies to both of the fuel tank side covers. 1. Remove: Fuel tank side cover "1" a. Remove the screw on the fuel tank side cover. b. Slide the fuel tank side cover to the front and then remove the three tabs "a".

The following procedure applies to both of the fuel tank side covers. 1. Remove: Fuel tank side cover "1" a. Remove the screw on the fuel tank side cover. b. Slide the fuel tank side cover to the front and then remove the three tabs "a".

Removing the fuel tank

1. Extract the fuel in the fuel tank through the fuel tank cap with a pump. 2. Remove: Fuel tank breather hose Fuel tank overflow hose Fuel pump coupler Fuel sender coupler Fuel hose connector cover Fuel hose Warning: Cover fuel hose connections...

1. Extract the fuel in the fuel tank through the fuel tank cap with a pump. 2. Remove: Fuel tank breather hose Fuel tank overflow hose Fuel pump coupler Fuel sender coupler Fuel hose connector cover Fuel hose Warning: Cover fuel hose connections...

Removing the fuel pump

1. Remove: Fuel pump Notice: Do not drop the fuel pump or give it a strong shock. Do not touch the base section of the fuel sender.

1. Remove: Fuel pump Notice: Do not drop the fuel pump or give it a strong shock. Do not touch the base section of the fuel sender.

Checking the fuel pump body

1. Check: Fuel pump body Obstruction → Clean. Cracks/damage → Replace fuel pump assembly.

1. Check: Fuel pump body Obstruction → Clean. Cracks/damage → Replace fuel pump assembly.

Checking the fuel pump operation

1. Check: Fuel pump operation Refer to " Checking the fuel pressure ".

1. Check: Fuel pump operation Refer to " Checking the fuel pressure ".

Installing the fuel pump

1. Install: Fuel pump gasket New Fuel pump Fuel pump bracket Fuel pump bracket bolt 4 Nm (0.4 m·kgf, 2.9 ft·lbf). Do not damage the installation surfaces of the fuel tank when installing the fuel pump. Always use a new fuel pump gasket. Install the...

1. Install: Fuel pump gasket New Fuel pump Fuel pump bracket Fuel pump bracket bolt 4 Nm (0.4 m·kgf, 2.9 ft·lbf). Do not damage the installation surfaces of the fuel tank when installing the fuel pump. Always use a new fuel pump gasket. Install the...

Installing the fuel tank

1. Connect: Fuel tank breather hose (fuel tank to hose joint) "1" Fuel tank overflow hose (fuel tank to hose joint) "2" Fuel tank breather hose "3" Fuel tank overflow hose "4" 2. Connect: Fuel hose (fuel tank side) Notice: When installing the fuel...

1. Connect: Fuel tank breather hose (fuel tank to hose joint) "1" Fuel tank overflow hose (fuel tank to hose joint) "2" Fuel tank breather hose "3" Fuel tank overflow hose "4" 2. Connect: Fuel hose (fuel tank side) Notice: When installing the fuel...

Installing the fuel tank side covers

The following procedure applies to both of the fuel tank side covers. 1. Install: Fuel tank side cover "1" a. Fit the tabs "a" of the fuel tank side cover. b. Slide the fuel tank side cover to the rear and then fit the tabs. c. Install the screw on...

The following procedure applies to both of the fuel tank side covers. 1. Install: Fuel tank side cover "1" a. Fit the tabs "a" of the fuel tank side cover. b. Slide the fuel tank side cover to the rear and then fit the tabs. c. Install the screw on...

Removing the air filter case and secondary injectors

Order Job/Parts to remove Quantity Remarks Fuel tank Refer to " Fuel tank ". 1 Crankcase breather hose 1 Disconnect. 2 Sub-wire harness coupler 1 Disconnect. 3 Fuel hose (secondary injector fuel rail side) 1 Disconnect. 4 Upper air filter case 1 5...

Order Job/Parts to remove Quantity Remarks Fuel tank Refer to " Fuel tank ". 1 Crankcase breather hose 1 Disconnect. 2 Sub-wire harness coupler 1 Disconnect. 3 Fuel hose (secondary injector fuel rail side) 1 Disconnect. 4 Upper air filter case 1 5...

Checking the secondary injectors (before removing)

1. Check: Injectors Use the diagnostic code number "D:40-D:43". Refer to " Diagnostic mode ".

1. Check: Injectors Use the diagnostic code number "D:40-D:43". Refer to " Diagnostic mode ".

Removing the fuel hose (primary injector joint side and secondary injector joint side)

1. Remove: Fuel hose (primary injector joint side and secondary injector joint side) Warning: Cover fuel hose connections with a cloth when disconnecting them. Residual pressure in the fuel lines could cause fuel to spurt out when removing the...

1. Remove: Fuel hose (primary injector joint side and secondary injector joint side) Warning: Cover fuel hose connections with a cloth when disconnecting them. Residual pressure in the fuel lines could cause fuel to spurt out when removing the...

Removing the secondary injectors

Warning: Check the injectors in a well-ventilated area free of combustible materials. Make sure that there is no smoking or use of electric tools in the vicinity of the injectors. Be careful when disconnecting the fuel hoses. Any remaining pressure...

Warning: Check the injectors in a well-ventilated area free of combustible materials. Make sure that there is no smoking or use of electric tools in the vicinity of the injectors. Be careful when disconnecting the fuel hoses. Any remaining pressure...

Removing the lower air filter case

1. Remove: Lower air filter case a. Push the four tabs "a" in the direction shown in the illustration and separate the lower air filter case from air filter case duct. b. Loosen the intake funnel joint bolts.

1. Remove: Lower air filter case a. Push the four tabs "a" in the direction shown in the illustration and separate the lower air filter case from air filter case duct. b. Loosen the intake funnel joint bolts.

Removing the intake funnel assembly

1. Remove: Intake funnel servo motor rod assembly Intake funnel assembly a. Clamp the two tabs "a" in the direction shown in the illustration and separate the intake funnel assembly from lower air filter case. Notice: Do not remove the bolts "1"...

1. Remove: Intake funnel servo motor rod assembly Intake funnel assembly a. Clamp the two tabs "a" in the direction shown in the illustration and separate the intake funnel assembly from lower air filter case. Notice: Do not remove the bolts "1"...

Checking the secondary injectors

1. Check: Injectors Obstruction → Replace and check the fuel pump/fuel supply system. Deposit → Replace. Damage → Replace. 2. Check: Injector resistance Refer to " Checking the fuel injectors ".

1. Check: Injectors Obstruction → Replace and check the fuel pump/fuel supply system. Deposit → Replace. Damage → Replace. 2. Check: Injector resistance Refer to " Checking the fuel injectors ".

Checking the air filter case seal

1. Check: Air filter case seal "1". Damage → Replace.

1. Check: Air filter case seal "1". Damage → Replace.

Checking the intake funnel

1. Check: Intake funnel servo motor rod assembly. Damage/scratches → Replace. Intake funnel assembly. Cracks/damage → Replace. 2. Check: Intake funnel movement Sticks → Replace the intake funnel assembly. Notice: Make sure that the intake funnel...

1. Check: Intake funnel servo motor rod assembly. Damage/scratches → Replace. Intake funnel assembly. Cracks/damage → Replace. 2. Check: Intake funnel movement Sticks → Replace the intake funnel assembly. Notice: Make sure that the intake funnel...

Installing the intake funnel and lower air filter case

1. Install: Lower air filter case Intake funnel servo motor rod assembly Intake funnel assembly Intake funnel joint bolts Intake funnel joint bolt 8 Nm (0.8 m·kgf, 5.8 ft·lbf).

1. Install: Lower air filter case Intake funnel servo motor rod assembly Intake funnel assembly Intake funnel joint bolts Intake funnel joint bolt 8 Nm (0.8 m·kgf, 5.8 ft·lbf).

Checking the intake funnel operation

1. Check: Intake funnel servo motor operation a. Activate the diagnostic mode and select the diagnostic code number "D:34". Refer to " Fuel injection system ". b. Set the engine stop switch to "o". c. Check that the intake funnel operate smoothly...

1. Check: Intake funnel servo motor operation a. Activate the diagnostic mode and select the diagnostic code number "D:34". Refer to " Fuel injection system ". b. Set the engine stop switch to "o". c. Check that the intake funnel operate smoothly...

Installing the secondary injectors

Notice: Always use new O-rings. When checking the injectors, do not allow any foreign material to enter or adhere to the injectors, fuel rails, or O-rings. Be careful not to twist or pinch the Orings when installing the injectors. If an injector is...

Notice: Always use new O-rings. When checking the injectors, do not allow any foreign material to enter or adhere to the injectors, fuel rails, or O-rings. Be careful not to twist or pinch the Orings when installing the injectors. If an injector is...

Installing the upper air filter case

1. Install: Upper air filter case seal "1" New Secondary injector assembly seal "2" New The matching adhesion portion of the seal should be positioned within a range of "a". 2. Install: Upper air filter case Upper air filter case screw 2 Nm (0.2...

1. Install: Upper air filter case seal "1" New Secondary injector assembly seal "2" New The matching adhesion portion of the seal should be positioned within a range of "a". 2. Install: Upper air filter case Upper air filter case screw 2 Nm (0.2...

Installing the fuel hose (primary injector joint side and secondary injector joint side)

1. Connect: Fuel hose (primary injector joint side and secondary injector joint side) Notice: When installing the fuel hose, make sure that it is securely connected, and that the fuel hose connector cover on the fuel hose is in the correct position,...

1. Connect: Fuel hose (primary injector joint side and secondary injector joint side) Notice: When installing the fuel hose, make sure that it is securely connected, and that the fuel hose connector cover on the fuel hose is in the correct position,...

Removing the canister

Order Job/Parts to remove Quantity Remarks Fuel tank Refer to " Fuel tank ". Air filter case Refer to " Air filter case ". 1 Canister purge hose (throttle body-#2 to 3-way joint) 1 2 Canister purge hose (throttle body-#1 to 3-way joint) 1 3 3-way...

Order Job/Parts to remove Quantity Remarks Fuel tank Refer to " Fuel tank ". Air filter case Refer to " Air filter case ". 1 Canister purge hose (throttle body-#2 to 3-way joint) 1 2 Canister purge hose (throttle body-#1 to 3-way joint) 1 3 3-way...

Removing the throttle body assembly

Order Job/Parts to remove Quantity Remarks Fuel tank Refer to " Fuel tank ". Air filter case Refer to " Air filter case ". 1 Throttle position sensor coupler 1 Disconnect. 2 Accelerator position sensor coupler 1 Disconnect. 3 Sub-wire harness...

Order Job/Parts to remove Quantity Remarks Fuel tank Refer to " Fuel tank ". Air filter case Refer to " Air filter case ". 1 Throttle position sensor coupler 1 Disconnect. 2 Accelerator position sensor coupler 1 Disconnect. 3 Sub-wire harness...

Removing the primary injectors

Order Job/Parts to remove Quantity Remarks 1 Primary injector coupler #1 1 Disconnect. 2 Primary injector coupler #2 1 Disconnect. 3 Primary injector coupler #3 1 Disconnect. 4 Primary injector coupler #4 1 Disconnect. 5 Sub-wire harness 1 6 Intake...

Order Job/Parts to remove Quantity Remarks 1 Primary injector coupler #1 1 Disconnect. 2 Primary injector coupler #2 1 Disconnect. 3 Primary injector coupler #3 1 Disconnect. 4 Primary injector coupler #4 1 Disconnect. 5 Sub-wire harness 1 6 Intake...

Checking the primary injectors (before removing)

1. Check: Injectors Use the diagnostic code number "D:36-D:39". Refer to " Diagnostic mode ".

1. Check: Injectors Use the diagnostic code number "D:36-D:39". Refer to " Diagnostic mode ".

Removing primary injectors

Warning: Check the injectors in a well-ventilated area free of combustible materials. Make sure that there is no smoking or use of electric tools in the vicinity of the injectors. Be careful when disconnecting the fuel hoses. Any remaining pressure...

Warning: Check the injectors in a well-ventilated area free of combustible materials. Make sure that there is no smoking or use of electric tools in the vicinity of the injectors. Be careful when disconnecting the fuel hoses. Any remaining pressure...

Checking the primary injectors

1. Check: Injectors Obstruction → Replace and check the fuel pump/fuel supply system. Deposit → Replace. Damage → Replace. 2. Check: Injector resistance Refer to " Checking the fuel injectors ".

1. Check: Injectors Obstruction → Replace and check the fuel pump/fuel supply system. Deposit → Replace. Damage → Replace. 2. Check: Injector resistance Refer to " Checking the fuel injectors ".

Checking the rollover valve (for California only)

1. Check: Rollover valve "1". Damage/faulty → Replace. Check that air flows smoothly only in the direction of the arrow shown in the illustration. The rollover valve must be in an upright position when checking the airflow.

1. Check: Rollover valve "1". Damage/faulty → Replace. Check that air flows smoothly only in the direction of the arrow shown in the illustration. The rollover valve must be in an upright position when checking the airflow.

Checking and cleaning the throttle bodies

Clean the throttle bodies only if they cannot be synchronized using the bypass air screws. Before cleaning the throttle bodies, check the following items: Valve clearance Spark plugs Air filter element Throttle body joints Fuel hoses Air induction...

Clean the throttle bodies only if they cannot be synchronized using the bypass air screws. Before cleaning the throttle bodies, check the following items: Valve clearance Spark plugs Air filter element Throttle body joints Fuel hoses Air induction...

Installing the primary injectors

Notice: Always use new O-rings. When checking the injectors, do not allow any foreign material to enter or adhere to the injectors, fuel rails, or O-rings. Be careful not to twist or pinch the Orings when installing the injectors. If an injector is...

Notice: Always use new O-rings. When checking the injectors, do not allow any foreign material to enter or adhere to the injectors, fuel rails, or O-rings. Be careful not to twist or pinch the Orings when installing the injectors. If an injector is...

Checking the injector pressure

After installing the injectors, perform the following steps to check the injector pressure. Do not allow any foreign materials to enter the fuel lines. 1. Check: Injector pressure a. Connect the injector pressure adapter "1" to the primary injector...

After installing the injectors, perform the following steps to check the injector pressure. Do not allow any foreign materials to enter the fuel lines. 1. Check: Injector pressure a. Connect the injector pressure adapter "1" to the primary injector...

Checking the fuel pressure

1. Check: Fuel pressure a. Remove the fuel tank bolt and holdup the fuel tank. b. Disconnect the fuel hose "1" from the fuel tank. Cover fuel hose connections with a cloth when disconnecting them. Residual pressure in the fuel lines could cause fuel...

1. Check: Fuel pressure a. Remove the fuel tank bolt and holdup the fuel tank. b. Disconnect the fuel hose "1" from the fuel tank. Cover fuel hose connections with a cloth when disconnecting them. Residual pressure in the fuel lines could cause fuel...

Adjusting the throttle position sensor

Warning: Handle the throttle position sensor with special care. Never subject the throttle position sensor to strong shocks. If the throttle position sensor is dropped, replace it. 1. Check: Throttle position sensor Refer to " Checking the throttle...

Warning: Handle the throttle position sensor with special care. Never subject the throttle position sensor to strong shocks. If the throttle position sensor is dropped, replace it. 1. Check: Throttle position sensor Refer to " Checking the throttle...

Adjusting the accelerator position sensor

Warning: Handle the accelerator position sensor with special care. Never subject the accelerator position sensor to strong shocks. If the accelerator position sensor is dropped, replace it. 1. Check: Accelerator position sensor Refer to " Checking...

Warning: Handle the accelerator position sensor with special care. Never subject the accelerator position sensor to strong shocks. If the accelerator position sensor is dropped, replace it. 1. Check: Accelerator position sensor Refer to " Checking...

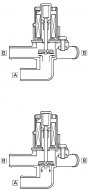

Air induction system

1. Lower air filter case; 2. Air induction system hose (air filter case to air cut-off valve); 3. Air cut-off valve; 4. Air induction system hose (air cut-off valve to reed valve cover)

1. Lower air filter case; 2. Air induction system hose (air filter case to air cut-off valve); 3. Air cut-off valve; 4. Air induction system hose (air cut-off valve to reed valve cover)

Removing the air cut-off valve assembly and hoses

Order Job/Parts to remove Quantity Remarks Fuel tank Refer to " Fuel tank ". Air filter case Refer to " Air filter case ". 1 Side air filter case duct 2 2 Atmospheric pressure sensor coupler 1 Disconnect. 3 Air filter case duct 1 4 Atmospheric...

Order Job/Parts to remove Quantity Remarks Fuel tank Refer to " Fuel tank ". Air filter case Refer to " Air filter case ". 1 Side air filter case duct 2 2 Atmospheric pressure sensor coupler 1 Disconnect. 3 Air filter case duct 1 4 Atmospheric...

Removing the reed valves

Order Job/Parts to remove Quantity Remarks 1 Reed valve cover 2 2 Reed valve assembly 2 3 Reed valve plate 4 For installation, reverse the removal procedure.

Order Job/Parts to remove Quantity Remarks 1 Reed valve cover 2 2 Reed valve assembly 2 3 Reed valve plate 4 For installation, reverse the removal procedure.

Checking the air induction system

Air injection The air induction system burns unburned exhaust gases by injecting fresh air (secondary air) into the exhaust port, reducing the emission of hydrocarbons. When there is negative pressure at the exhaust port, the reed valve opens,...

Air injection The air induction system burns unburned exhaust gases by injecting fresh air (secondary air) into the exhaust port, reducing the emission of hydrocarbons. When there is negative pressure at the exhaust port, the reed valve opens,...

Installing the air induction system

1. Install: Reed valves Reed valve stoppers Reed valve base 2. Install: Reed valve plate Align the projection "a" on the cylinder head cover "1" with the hole "b" in the reed valve plate. Reed valve assembly Install the reed valve assembly so that...

1. Install: Reed valves Reed valve stoppers Reed valve base 2. Install: Reed valve plate Align the projection "a" on the cylinder head cover "1" with the hole "b" in the reed valve plate. Reed valve assembly Install the reed valve assembly so that...

Similar subsections of other motorcycle models

Fuel and exhaust system motorcycle Ducati ST2 (1997-2003)

Fuel and exhaust system motorcycle Honda CB 400 SF (1992-1999, 1 generation)

Fuel and exhaust systems motorcycle Suzuki Boulevard M109R (2006-2025)

Fuel and control system motorcycle Triumph Rocket III (2004-2018)

- Information for owner

- Motorcycle design

- Technical tricks

- Technical characteristics

- Maintenance

- Troubleshooting

- Engine and systems

- Engine repair

- Cooling system

- Lubrication system

- Fuel system

- Fuel injection

- Transmission

- Running gear and frame

- Frame and hinged elements

- Front suspension and handlebar

- Rear suspension

- Brake system

- Wheels and tires

- Electric equipment

- Starting and charging system

- Equipment and devices