XL600V-H and V-L models (1987 to 1990)

Removal

1. Position the motorcycle on its centrestand if fitted or on an auxiliary stand and support it so that the rear wheel is off the ground. Always make sure the motorcycle is properly supported.

2. Fully unscrew the adjusting wingnut on the end of the brake rod, then pivot the arm rearwards and off the rod. Take care not to lose the spring that locates between the arm and the but on the rod.

3. Slacken the rear axle nut.

4. Slacken the locknut on the adjuster on each end of the swingarm, then turn the adjuster nut out on each side to provide some slack in the chain. Move the rear wheel forwards In the swingarm to create the slack.

5. Unscrew the axle nut and remove the washer, noting how it locates.

6. Support the wheel, then withdraw the axle from the left-hand side and lower the wheel to the ground. Disengage the chain from the sprocket and remove the wheel from the swingarm. If the axle is difficult to withdraw, drive it through, making sure you don't damage the threads.

Caution: Do not lay the wheel down and allow it to rest on the sprocket - it could become warped. Set the wheel on wood blocks so the sprocket doesn't support the weight of the wheel.

7. Remove the spacer from the left-hand side of the wheel.

8. Check the axle for straightness by rolling it on a flat surface such as a piece of plate glass (if the axle Is corroded, first remove the corrosion with fine emery cloth). If the equipment is available, place the axle in V-blocks and check the runout using a dial gauge. If the axle is bent or the runout exceeds the limit specified at the beginning of the Chapter, replace it with a new one.

9. Check the condition of the grease seals and wheel bearings (see Section 15).

Installation

10. Apply a smear of grease to the inside of the wheel spacer, and also to the outside it fits into the wheel. Fit the spacer into the lefthand side.

11. Manoeuvre the wheel so that it is in between the ends of the swingarm. Apply a thin coat of grease to the axle. Make sure the brake plate is correctly fitted into the drum and that the sprocket carrier is correctly fitted in the hub.

12. Engage the drive chain with the sprocket and lift the wheel into position. Make sure the spacer remains correctly in place, and that the slot in the brake plate locates over the lug on the swingarm to prevent it turning.

13. Install the axle from the left, making sure it passes through the chain adjusters. Check that everything is correctly aligned.

14. Fit the washer, making sure its squared edge locates correctly under the swingarm, then fit the nut.

15. Make sure the spring is located on the brake rod, then pivot the brake arm rearwards and slide it onto the rod.

16. Now check and adjust the drive chain slack (see Chapter 1). On completion tighten the axle nut to the torque setting specified at the beginning of the Chapter, counter-holding the axle head on the other side of the wheel to prevent it turning if necessary.

17. Operate the brake pedal several times to bring the shoes into contact with the drum. Check the operation of the rear brake carefully before riding the bike.

XL600V-M models onward (1991-on), XL650V and XRV750 models

Removal

18. Position the motorcycle on its centrestand if fitted or on an auxiliary stand and support it so that the rear wheel is off the ground. Always make sure the motorcycle is properly supported.

19. On all XL600V models, remove the brake caliper rear bolt and pivot it up (see Section 5).

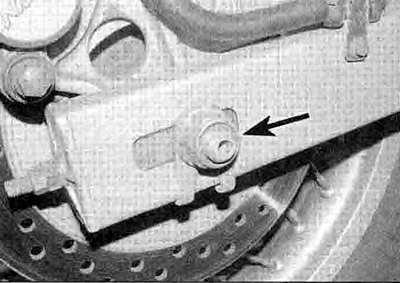

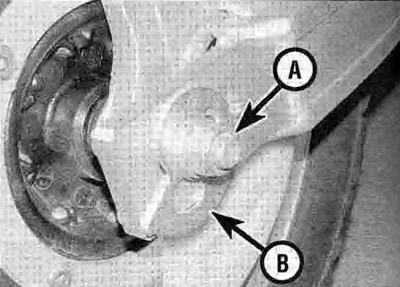

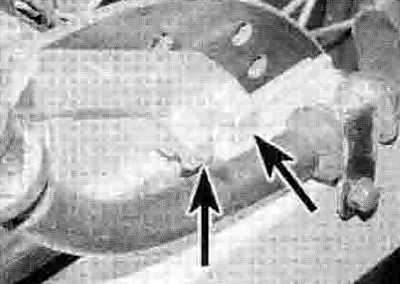

20. Slacken the rear axle nut (see illustrations).

14.20a. Axle nut (arrowed) - XL models

14.20b. Axle nut (A) and eccentric adjuster (B) - XRV models

21. On XL models, slacken the locknut on the adjuster on each end of the swingarm, then turn the adjuster nut out on each side to provide some slack in the chain (see illustrations). On XRV models, turn the eccentric adjuster on each side to provide some slack in the chain (see illustration 14.20b). Move the rear wheel forwards in the swingarm to create the slack.

14.21a. Slacken the locknut (arrowed)...

14.21b ...then turn the adjuster out to provide slack

22. Unscrew the axle nut and remove Ilie washer, on XL models noting how it locates (see illustration 14.20a). On XRV models remove the right-hand adjuster from the end of the axle (see illustration 14.20b).

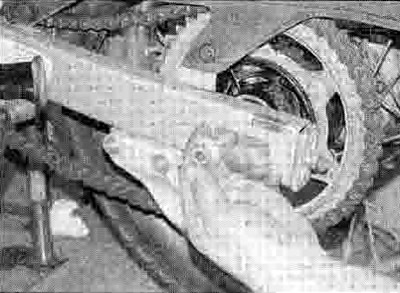

23. Support the wheel, then withdraw the axle from the left-hand side and lower the wheel to the ground (see illustration). Disengage the chain from the sprocket and remove the wheel from the swingarm (see illustration). If the axle is difficult to withdraw, drift it through, making sure you don't damage the threads. On XRV750 retrieve the left-hand chain adjuster from the axle or the floor.

14.23a. Withdraw the axle...

14.23b ...then lower the wheel to the ground and disengage the chain

24. Note how the rear brake caliper bracket locates against the swingarm, and support It so that It will not fall off. If required, displace it from the swingarm. noting how it fits, and tie it up, making sure no strain is placed on the hose.

Caution: Do not lay the wheel down and allow it to rest on the disc or the sprocket -they could become warped. Set the wheel on wood blocks so the disc or the sprocket doesn't support the weight of the wheel. Do not operate the brake pedal with the wheel removed.

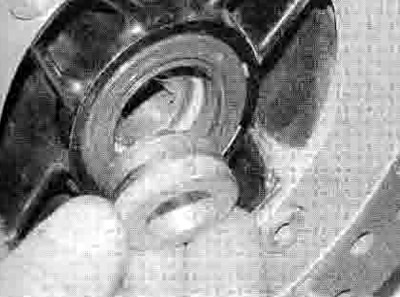

25. Remove the spacer from each side of the wheel for safekeeping, noting which fits where (see illustrations).

14.25a. Remove the spacer from the righthand side...

14.25b ...and from the left-hand side, noting which fits where

26. Check the axle for straightness by rolling it on a flat surface such as a piece of plate glass (if the axle is corroded, first remove the corrosion with fine emery cloth). If the equipment is available, place the axle in V-blocks and check the runout using a dial gauge. If the axle is bent or the runout exceeds the limit specified at the beginning of the Chapter, replace it with a new one.

27. Check the condition of the grease seals and wheel bearings (see Section 15).

Installation

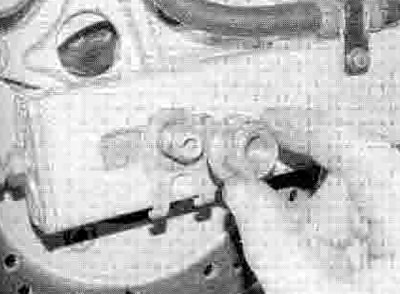

28. Apply a smear of grease to the inside of the wheel spacers, and also to the outside where they fit into the wheel. Fit the short spacer into the right-hand side of the wheel and the long spacer into the left-hand side (see illustrations 14.25a and b). If displaced, fit the brake caliper bracket onto the swingarm, making sure it locates correctly (see illustrations).

14.28a. Make sure the brake caliper locates correctly (arrows) - XL600V

14.28b. Make sure the brake caliper locates correctly (arrow) - XL650V

14.28c. Make sure the brake caliper locates correctly (arrows) - XRV750

29. Manoeuvre the wheel so that it is in between the ends of the swingarm. Apply a thin coat of grease to the axle. Make sure the brake caliper bracket is still correctly positioned against the swingarm and the sprocket carrier is correctly fitted in the hub.

30. Engage the drive chain with the sprocket and lift the wheel into position (see illustration 14.23b). Make sure the spacers and caliper bracket and sprocket carrier remain correctly in place and that the brake disc fits squarely into the caliper, with the pads positioned correctly each side of the disc.

31. On XRV750 models fit the left-hand chain adjuster onto the axle, making sure it is the correct way round. On all models install the axle from the left, on XL models making sure it passes through the chain adjusters (see illustration 14.23a). Check that everything is correctly aligned.

32. On XL models, fit the washer, making sure its squared edge locates correctly under the swingarm, then fit the nut (see illustrations). On XRV models fit the right-hand adjuster onto the end of the axle, making sure it is the correct way round, then fit the washer and nut (see illustration 14.20b).

14.32a. Fit the shaped washer, making sure it locates correctly...

14.32b ...then fit the nut

33. Now check and adjust the drive chain slack (see Chapter 1). On completion tighten the axle nut to the torque setting specified at the beginning of the Chapter, counter-holding the axle head on the other side of the wheel to prevent it turning if necessary.

34. Operate the brake pedal several times to bring the pads into contact with the disc. Check the operation of the rear brake carefully before riding the bike.