Air injection

The air induction system burns unburned exhaust gases by injecting fresh air (secondary air) into the exhaust port, reducing the emission of hydrocarbons. When there is negative pressure at the exhaust port, the reed valve opens, allowing secondary air to flow into the exhaust port. The required temperature for burning the unburned exhaust gases is approximately 600 to 700°C.

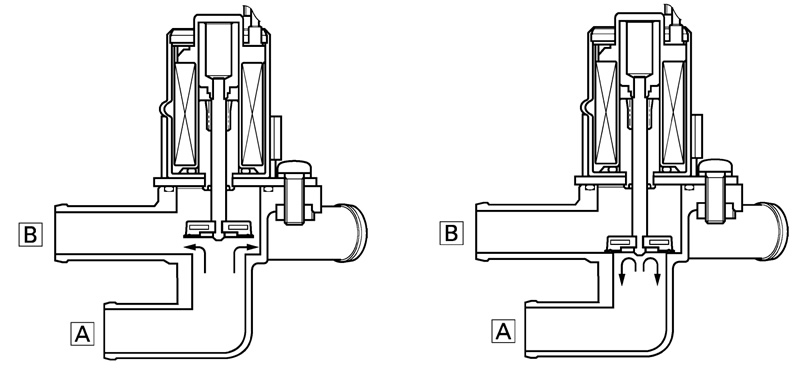

Air cut-off valve

The air cut-off valve is controlled by the signals from the ECU in accordance with the combustion conditions. Ordinarily, the air cut-off valve opens to allow the air to flow during idle and closes to cut-off the flow when the vehicle is being driven. However, if the coolant temperature is below the specified value, the air cut-off valve remains open and allows the air to flow into the exhaust pipe until the temperature becomes higher than the specified value.

A. From the air cleaner; B. To the cylinder head

1. Check:

- Hoses

Loose connections → Connect properly.

Cracks/damage → Replace.

- Pipes

Cracks/damage → Replace.

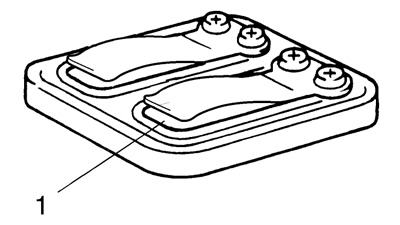

2. Check:

- Reed valve «1»

- Reed valve stopper

- Reed valve seat

Cracks/damage → Replace the reed valve.

3. Measure:

- Reed valve bending limit «a»

Out of specification → Replace the reed valve.

Reed valve bending limit: 0.4 mm (0.016 in).

4. Check:

- Air cut-off valve

Cracks/damage → Replace.

5. Check:

- Air induction system solenoid

a. Remove the air induction system solenoid coupler from the wire harness.

b. Connect the pocket tester (Ωx1) to the air induction system solenoid terminals as shown.

Positive tester probe: Brown terminal «1»

Negative tester probe: Brown/Red terminal «2»

c. Measure the air induction system solenoid resistance.

Air induction system solenoid resistance: 18-22Ω at 20°C (68°F).

d. Out of specification → Replace.