- Drive chain

Notice: Be sure to put on safety goggles when working.

Drive chain cut & rivet tool 90890-01550 YM-01550.

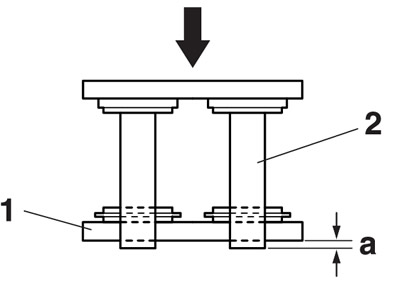

a. When press fitting the connecting plate "1", make sure the space "a" between the end of the connecting pin "2" and the connecting plate is 1.2-1.4 mm (0.05-0.06 in).

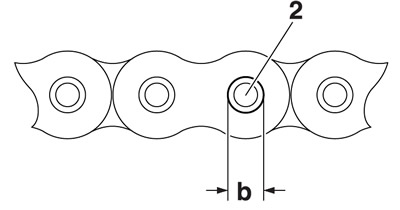

b. After riveting, make sure the length between the edges "b" of the connecting pin "2" is 5.7-6.0 mm (0.22-0.24 in).

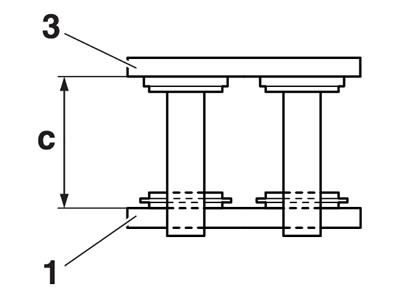

c. After riveting, make sure the space "c", which is inside of the connecting link "3" and inside of the connecting plate "1", is 16.3-16.5 mm (0.64-0.65 in).

2. Lubricate:

- Drive chain

Recommended lubricant. Chain lubricant suitable for O-ring chains.

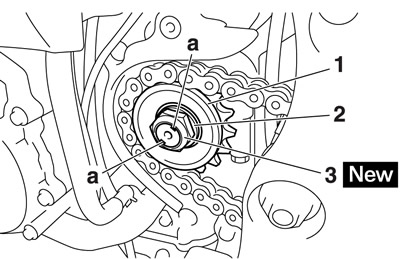

3. Install:

- Drive sprocket "1"

- Washer "2"

- Drive sprocket nut "3"

Drive sprocket nut 85 Nm (8.5 m·kgf, 61 ft·lbf).

- While applying the rear brake, tighten the drive sprocket nut.

- Stake the drive sprocket nut at cutouts, "a" in the drive axle.

Notice: Never install a new drive chain onto worn drive chain sprockets; this will dramatically shorten the drive chain's life.

4. Adjust:

- Drive chain slack

Refer to "Adjusting the drive chain slack".

Drive chain slack (when adjusting the drive chain) 25.0-35.0 mm (0.98-1.38 in).

Drive chain slack (when replacing the drive chain and sprocket) 20.0-30.0 mm (0.79-1.18 in).

Notice: A drive chain that is too tight will overload the engine and other vital parts, and one that is too loose can skip and damage the swingarm or cause an accident. Therefore, keep the drive chain slack within the specified limits.