Max. horizontal runout which can be eliminated by centering — 2.0 mm (0.08 in)

Note: Vertical runout cannot be compensated for by centering the rim.

Centering lateral runout

Determine maximum deviation (plus (+) and minus (-)).

Note: To center the wheel, the spoke nipples must be tightened on the side directly opposite the largest deviation.

Remove grub screw from relevant spoke nipple before tightening.

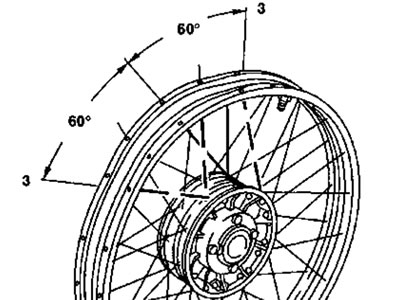

Working forwards and backwards from the point opposite the maximum and minimum value points, take up slack at every third spoke nipple.

Then working forwards and backwards from the point opposite the maximum and minimum value points, take up slack at every second spoke nipple.

Caution! Never attempt to compensate for the entire horizontal runout at only one or two spokes.

Four spokes are therefore tightened during each centering operation.

Check horizontal runout with a dial gauge.

After every correction of horizontal runout, recheck vertical runout.

If necessary, repeat the centering operation.

Lock tightened spokes into place with grub screws.

Tightening torque:

- Spoke nipple — 3.5-5 Nm

- Grub screw — 1 Nm