General

The rear brake master cylinder is mounted transverse to the centerline, beneath the rear fork pivot shaft assembly.

If the rear brake feels spongy or excessive pedal travel exists or the brake does not work at all, proceed to Inspection.

Notes:

- Use only CCI #20 BRAKE GREASE to lubricate master cylinder bores, pistons, primary cups and secondary cups.

- Use only KS62F assembly grease on caliper pistons and piston seals.

- Use only G40M BRAKE GREASE on the caliper pins and boots.

Caution! Direct contact of DOT 4 brake fluid with eyes can cause irritation. Avoid eye contact. In case of eye contact flush with large amounts of water and get medical attention. Swallowing large amounts of DOT 4 brake fluid can cause digestive discomfort. If swallowed, obtain medical attention. Use in well ventilated area. KEEP OUT OF REACH OF CHILDREN.

Notice: DOT 4 brake fluid will damage painted and body panel surfaces it comes in contact with. Always use caution and protect surfaces from spills whenever brake work is performed. Failure to comply can result in cosmetic damage.

Note. If DOT 4 BRAKE FLUID contacts painted surfaces, IMMEDIATELY flush area with clear water.

Inspection

1. Check the fluid level in the rear brake reservoir. If it is low, refill and bleed brake system. See 2.17 BLEEDING BRAKES.

2. Check for fluid leaks in the brake line, around banjo fittings or rear brake caliper piston or bleeder valve. Repair brake system.

- a. Brake Line: See 2.16 BRAKE LINES.

- b. Brake Caliper: See 2.14 REAR BRAKE CALIPER: XL MODELS.

3. Check rear brake friction pads and disc for excessive wear or damage. Replace as necessary.

- a. Brake Pads: See 1.16 BRAKE PADS AND DISCS: XL MODELS, Brake Pad Replacement: Rear.

- b. Brake Discs: See 2.5 WHEELS.

4. Check mechanical brake linkage from brake pedal to master cylinder for damage. Replace as necessary.

- a. Models with Mid-Mount Controls: See 2.40 RIDER FOOT CONTROLS: XL MID-MOUNT CONTROLS.

- b. Models with Forward Controls: See 2.41 RIDER FOOT CONTROLS: XL FORWARD CONTROLS.

5. Eliminate any air in the hydraulic brake assembly by bleeding the system. See 2.17 BLEEDING BRAKES.

If none of these conditions exist but the rear brake system does not operate properly, the rear master cylinder is defective. Replace or repair as necessary.

Removal

Caution! Direct contact of DOT 4 brake fluid with eyes can cause irritation. Avoid eye contact. In case of eye contact flush with large amounts of water and get medical attention. Swallowing large amounts of DOT 4 brake fluid can cause digestive discomfort. If swallowed, obtain medical attention. Use in well ventilated area. KEEP OUT OF REACH OF CHILDREN.

1. Drain rear brake master cylinder reservoir and remove hose clamp and feed hose from master cylinder feed hose port fitting. Discard hose clamp. See 2.13 REAR BRAKE MASTER CYLINDER RESERVOIR.

2. Remove bleeder nipple cap from bleeder valve on rear brake caliper. Install end of a length of 5/16 in (7.9 mm) ID clear plastic tubing over caliper bleeder valve, while placing free end in a suitable container.

Note. Dispose of brake fluid in accordance with local regulations.

3. Open bleeder valve about 1/2-turn. Pump brake pedal to drain brake fluid. Close bleeder valve but do not tighten.

4. Models with EVAP Controls: Remove EVAP canister and mounting bracket. See 4.20 EVAPORATIVE EMISSIONS CONTROL, Charcoal Canister.

Warning! Wear safety glasses or goggles when removing or installing retaining rings. Retaining rings can slip from the pliers and could be propelled with enough force to cause serious eye injury.

Note. Use correct retaining ring pliers and correct tips. Verify that tips are not excessively worn or damaged.

5. See Figure 2-83. Remove retaining ring (1) from clevis pin (2). Remove clevis pin and disengage master cylinder yoke (3) from bell crank (4). Discard retaining ring.

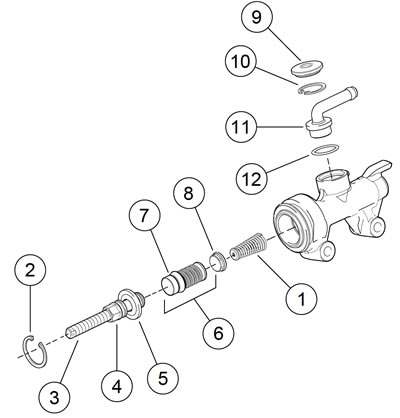

Figure 2-83. Rear brake master cylinder: 1. Retaining ring; 2. Clevis pin; 3. Yoke; 4. Bell crank; 5. Banjo bolt; 6. Sealing washer; 7. Screw; 8. Washer; 9. Mounting bracket; 10. Retaining ring; 11. Clevis pin; 12. Screw; 13. Screw

Note. Damaged banjo bolt surfaces will leak when reassembled. Prevent damage to seating surfaces by carefully removing brake line components.

6. Remove banjo bolt (5) and washers (6) from master cylinder. Lift banjo fitting away from master cylinder. Discard washers.

7. Remove two screws (7) and two washers (8) securing rear master cylinder to master cylinder mounting bracket (9) and remove rear master cylinder.

8. If it is necessary to remove master cylinder mounting bracket:

- a. Remove retaining ring (10) and clevis pin (11). Disconnect bell crank from mounting bracket.

- b. Remove two screws (12).

- c. Remove screw (13) and mounting bracket.

Disassembly

Notes:

- Do not disassemble the rear master cylinder unless problems are being experienced. Discard all seals during the disassembly procedure. Install a complete rebuild kit when the unit is reassembled.

- Clamp rear brake master cylinder in a vise by its mounting bosses only. Use brass or aluminum jaw covers or other protective device on vise jaws to prevent damage to master cylinder.

1. See Figure 2-84. Clamp rear brake master cylinder in a vise with yoke (1) pointing up.

Figure 2-84. Rear brake master cylinder: 1. Yoke; 2. External boot; 3. Spring pin; 4. Pushrod; 5. Spring retainer; 6. External spring; 7. Shoulder nut; 8. Inner boot

2. Remove external boot (2). Remove spring pin (3) from end of pushrod (4). Discard spring pin.

Note. Grip yoke by the edges with an adjustable wrench. Do not grip yoke by the flats or the yoke may become deformed.

Figure 2-85. Tightening yoke: 1. Incorrect; 2. Correct

3. Hold yoke with an adjustable wrench. Using an open-end wrench, loosen shoulder nut. Remove yoke.

Warning! Wear safety glasses or goggles when removing or installing spring. Spring tension can cause spring, attached components and/or hand tools to fly out which could result in death or serious injury.

4. Press down on spring retainer (5) to compress external return spring (6). While spring is compressed, remove shoulder nut from pushrod. Carefully release pressure on external return spring. Remove spring retainer and external return spring.

5. Remove and discard inner boot (8).

Note. Do not remove boot collar nut and pushrod retainer from pushrod.

Warning! Wear safety glasses or goggles when removing or installing retaining rings. Retaining rings can slip from the pliers and could be propelled with enough force to cause serious eye injury.

6. See Figure 2-86. Thread shoulder nut back onto pushrod several turns, to protect pushrod threads. Press down on pushrod to compress piston spring (1). Remove retaining ring (2).

Figure 2-86. Rear brake master cylinder: 1. Piston spring; 2. Retaining ring; 3. Pushrod; 4. Boot collar nut; 5. Pushrod retainer; 6. Piston; 7. Secondary cup; 8. Primary cup; 9. Dust cover; 10. Retaining ring; 11. Feed port fitting; 12. O-ring

7. Remove pushrod (3) with boot collar nut (4) and pushrod retainer (5), piston (6) with secondary cup (7), primary cup (8) and piston spring. Discard retaining ring, piston with secondary cup, primary cup and piston spring.

8. Remove dust cover (9), retaining ring (10), feed port fitting (11) and O-ring (12). Discard retaining ring and O-ring.

Cleaning and inspection

Warning! Use denatured alcohol to clean brake system components. Do not use mineral-based solvents (such as gasoline or paint thinner), which will deteriorate rubber parts even after assembly. Deterioration of these components can cause brake failure, which could result in death or serious injury.

Warning! Compressed air can pierce the skin and flying debris from compressed air could cause serious eye injury. Wear safety glasses when working with compressed air. Never use your hand to check for air leaks or to determine air flow rates.

1. Blow out drilled passages and piston bore in master cylinder body with low pressure compressed air from a clean air supply. Do not use a wire or similar instrument to clean drilled passages.

2. Carefully inspect all components.

- a. Inspect piston bore for damage. Replace as necessary.

- b. Inspect outlet port that mates with brake line banjo fitting. This is a critical sealing surface. Replace as necessary.

3. Verify that vent holes in master cylinder are completely open and free of dirt or debris.

Assembly

| FASTENER | TORQUE VALUE | |

| Brake master cylinder, rear, pushrod shoulder nut | 130-173 in·lbs | 14.7-19.6 Nm |

Notes:

- When assembling rear brake master cylinder, always use new parts from the service parts kit. See the parts catalog.

- Lubricate cylinder bore, cups and seals with CCI #20 BRAKE GREASE before assembly.

- Stand master cylinder on wooden block or clean, lint-free towel to protect seating surfaces.

1. Coat new O-ring with DOT 4 BRAKE FLUID. Install O-ring and feed port fitting into feed port on top of master cylinder.

Warning! Wear safety glasses or goggles when removing or installing retaining rings. Retaining rings can slip from the pliers and could be propelled with enough force to cause serious eye injury.

Note. Use correct retaining ring pliers and correct tips. Verify that tips are not excessively worn or damaged.

2. Secure with new retaining ring. Verify that retaining ring is fully seated in groove.

3. Slide dust cover onto feed port fitting. Press into place in master cylinder feed port. Turn feed port fitting so it points toward banjo fitting end of master cylinder body.

Note. Clamp rear brake master cylinder in a vise by its mounting bosses only. Use brass jaw covers or other protective device on vise jaws to prevent damage to master cylinder.

4. Clamp master cylinder in a vise with banjo fitting end pointing down.

5. See Figure 2-87. Lubricate master cylinder bore, new piston (1) with new secondary cup (3), and new primary cup (2) with CCI #20 BRAKE GREASE supplied in the service parts kit.

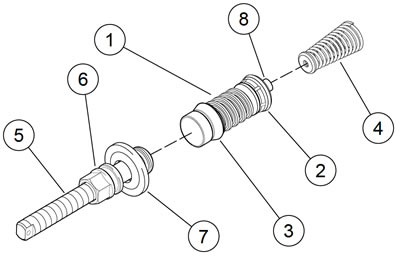

Figure 2-87. Rear master cylinder piston, pushrod and spring assembly: 1. Piston; 2. Primary cup; 3. Secondary cup; 4. Piston spring; 5. Pushrod; 6. Boot collar nut; 7. Pushrod retainer; 8. Piston spring mounting boss

Warning! Wear safety glasses or goggles when removing or installing spring. Spring tension can cause spring, attached components and/or hand tools to fly out which could result in death or serious injury.

6. Press small end of new piston spring (4) onto mounting boss (8) on piston (1).

7. Slide piston/spring assembly, flared end of spring first, into cylinder bore so that spring seats against counter bore (recess) at bottom of cylinder.

8. Apply approximately 0.1 g of G40M BRAKE GREASE to ball end of pushrod (5). Insert ball end of pushrod into cupped end of piston.

Warning! Wear safety glasses or goggles when removing or installing retaining rings. Retaining rings can slip from the pliers and could be propelled with enough force to cause serious eye injury.

9. Temporarily thread shoulder nut onto pushrod several turns to protect pushrod threads. Press down on pushrod to compress piston spring. Slide pushrod retainer down into master cylinder bore.

10. Secure pushrod assembly with new retaining ring. Verify that retaining ring is fully seated in groove. Remove shoulder nut from pushrod.

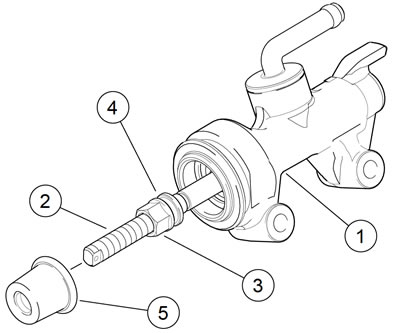

11. See Figure 2-88. Apply approximately 0.1 g of G40M BRAKE GREASE around groove (4) in boot collar nut (3). Carefully slide inner boot (5) down onto pushrod (2) and into end of master cylinder bore. Press lip of inner boot down around groove in boot collar nut.

Figure 2-88. Lubricating and installing inner boot: 1. Rear brake master cylinder assembly; 2. Pushrod; 3. Boot collar nut; 4. Groove; 5. Inner boot

12. Install external return spring and spring retainer. Thread shoulder nut shoulder-first onto pushrod several turns past flats.

13. Thread yoke onto pushrod, at least 2-3 turns past flats. Install new spring pin into end of pushrod.

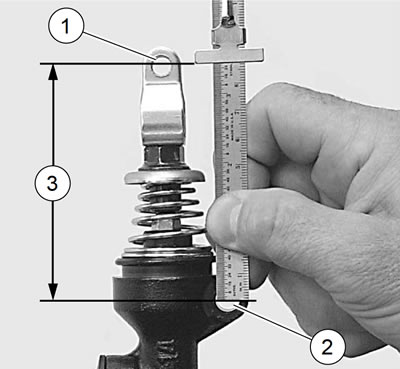

14. See Figure 2-89. Measure from centerline of clevis pin hole (1) in yoke to centerline of master cylinder mounting boss hole (2) closest to yoke.

Figure 2-89. Adjusting pushrod length: 1. Clevis pin hole; 2. Mounting boss hole; 3. 3.40-3.48 in (86.3-88.3 mm)

15. Turn yoke on pushrod to 3.40-3.48 in (86.3-88.3 mm).

Note. Grip yoke by the edges with adjustable wrench. Do not grip yoke by the flats or the yoke may become deformed.

16. Holding yoke with an adjustable wrench, turn shoulder nut back against yoke. Tighten to 130-173 in·lbs (14.7-19.6 Nm).

17. See Figure 2-90. Remove master cylinder assembly from vise. Slide external boot (2) over yoke/pushrod assembly and external return spring.

Figure 2-90. Assembled rear master cylinder: 1. Rear master cylinder assembly; 2. External boot; 3. Tabs (2); 4. Feed port fitting; 5. Banjo fitting hole

18. Install the external boot.

- a. Position external boot tabs (3) at the 3 o'clock and 9 o'clock position when master cylinder body (1) is held upright. The drain hole is at bottom of boot when master cylinder is mounted.

- b. Fit lip on large end of the external boot to groove in end of master cylinder.

- c. Seat the spring retainer in groove in small end of external boot.

Installation

| FASTENER | TORQUE VALUE | |

| Brake master cylinder mounting bracket, rear, screw: XL Models | 17-22 ft·lbs | 23.1-29.9 Nm |

| Brake master cylinder mounting bracket, rear, screw: XL Models | 17-22 ft·lbs | 23.1-29.9 Nm |

| Brake master cylinder, rear, mounting screw: XL Models | 17-22 ft·lbs | 23.1-29.9 Nm |

| Brake line banjo bolt | 20-25 ft·lbs | 27.1-33.9 Nm |

Warning! Wear safety glasses or goggles when removing or installing retaining rings. Retaining rings can slip from the pliers and could be propelled with enough force to cause serious eye injury.

Note. Use correct retaining ring pliers and correct tips. Verify that tips are not excessively worn or damaged.

1. See Figure 2-83. Install mounting bracket (9):

- a. Attach mounting bracket to frame loosely with screws (12, 13) and tighten two screws (12) to 17-22 ft·lbs (23.1-29.9 Nm).

- b. Tighten screw (13) to 17-22 ft·lbs (23.1-29.9 Nm).

2. Install bell crank (4) with clevis pin (11). Secure with new retaining ring (10).

3. Install rear master cylinder assembly on mounting bracket with screws (7) and washers (8). Tighten to 17-22 ft·lbs (23.1-29.9 Nm).

4. Fit yoke (3) onto bell crank (4). Install clevis pin (2) and secure with new retaining ring (1).

Note. Master cylinder housing has a positive stop for banjo fitting. When tightening banjo bolt into master cylinder in the next step, rotate banjo fitting clockwise until it contacts positive stop.

5. Position a new sealing washer (6) on each side of hydraulic brake line banjo fitting. Insert banjo bolt (5) through washers and fitting. Thread bolt into master cylinder housing. Tighten to 20-25 ft·lbs (27.1-33.9 Nm).

6. Install rear brake master cylinder feed hose on master cylinder feed hose port fitting. Secure with new hose clamp. See 2.13 REAR BRAKE MASTER CYLINDER RESERVOIR.

7. Models with EVAP Controls: Install the EVAP canister and mounting bracket. See 4.20 EVAPORATIVE EMISSIONS CONTROL, Charcoal Canister.

Caution! Direct contact of DOT 4 brake fluid with eyes can cause irritation. Avoid eye contact. In case of eye contact flush with large amounts of water and get medical attention. Swallowing large amounts of DOT 4 brake fluid can cause digestive discomfort. If swallowed, obtain medical attention. Use in well ventilated area. KEEP OUT OF REACH OF CHILDREN.

Notice: DOT 4 brake fluid will damage painted and body panel surfaces it comes in contact with. Always use caution and protect surfaces from spills whenever brake work is performed. Failure to comply can result in cosmetic damage.

Notes:

- If DOT 4 brake fluid contacts painted surfaces, IMMEDIATELY flush area with clear water.

- Rear brake master cylinder reservoir must be in a level position when filling and checking fluid level.

- Reservoir cover may be removed from rear brake master cylinder reservoir to more easily verify fluid level in reservoir.

- Use only DOT 4 BRAKE FLUID from a sealed container.

- Do not overfill reservoir. Do not reuse old brake fluid.

8. Position motorcycle upright (not resting on jiffy stand).

9. Remove reservoir cap.

10. Fill rear master cylinder reservoir with DOT 4 brake fluid until the fluid level reaches the UPPER mark on the reservoir.

11. Bleed brake system. See 2.17 BLEEDING BRAKES.

Warning! Be sure that all lights and switches operate properly before operating motorcycle. Low visibility of rider can result in death or serious injury.

12. Test operation of the stop lamp.

Warning! After servicing brakes and before moving motorcycle, pump brakes to build brake system pressure. Insufficient pressure can adversely affect brake performance, which could result in death or serious injury.

Warning! After repairing the brake system, test brakes at low speed. If brakes are not operating properly, testing at high speeds can cause loss of control, which could result in death or serious injury.

13. Test ride motorcycle at low speed.