Removal

Note. If only replacing brake pads, do not remove rear brake caliper. See 1.17 BRAKE PADS AND DISCS: XR 1200X.

Caution! Direct contact of DOT 4 brake fluid with eyes can cause irritation. Avoid eye contact. In case of eye contact flush with large amounts of water and get medical attention. Swallowing large amounts of DOT 4 brake fluid can cause digestive discomfort. If swallowed, obtain medical attention. Use in well ventilated area. KEEP OUT OF REACH OF CHILDREN.

Note. Damaged banjo bolt surfaces will leak when reassembled. Prevent damage to seating surfaces by carefully removing brake line components.

Notice: DOT 4 brake fluid will damage painted and body panel surfaces it comes in contact with. Always use caution and protect surfaces from spills whenever brake work is performed. Failure to comply can result in cosmetic damage.

Note. If DOT 4 brake fluid contacts painted surfaces, IMMEDIATELY flush area with clear water.

1. Position motorcycle on a suitable lift.

2. Place a suitable container under the rear caliper brake line banjo fitting to catch any brake fluid that may leak out. Do not reuse brake fluid.

Note. Dispose of brake fluid in accordance with local regulations.

3. Disconnect left shock absorber from rear fork. Rotate shock absorber out of the way.

4. Loosen rear axle nut and turn adjuster nuts to allow the rear wheel to move forward to the adjustment limit.

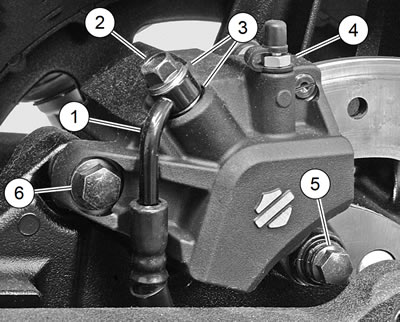

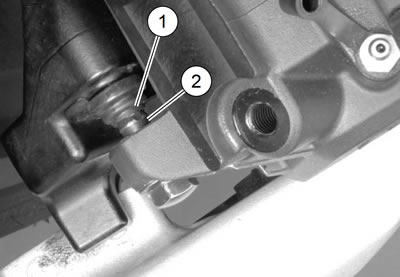

5. See Figure 2-112. Remove the banjo bolt (2) and both washers (3) to detach rear brake line (1) from brake caliper. Discard washers.

Figure 2-112. Rear caliper assembly: 1. Rear brake line; 2. Banjo bolt; 3. Washer (2); 4. Bleeder valve; 5. Mounting bolt; 6. Bolt pin

6. Remove mounting bolt (5) and bolt pin (6).

7. Remove caliper assembly.

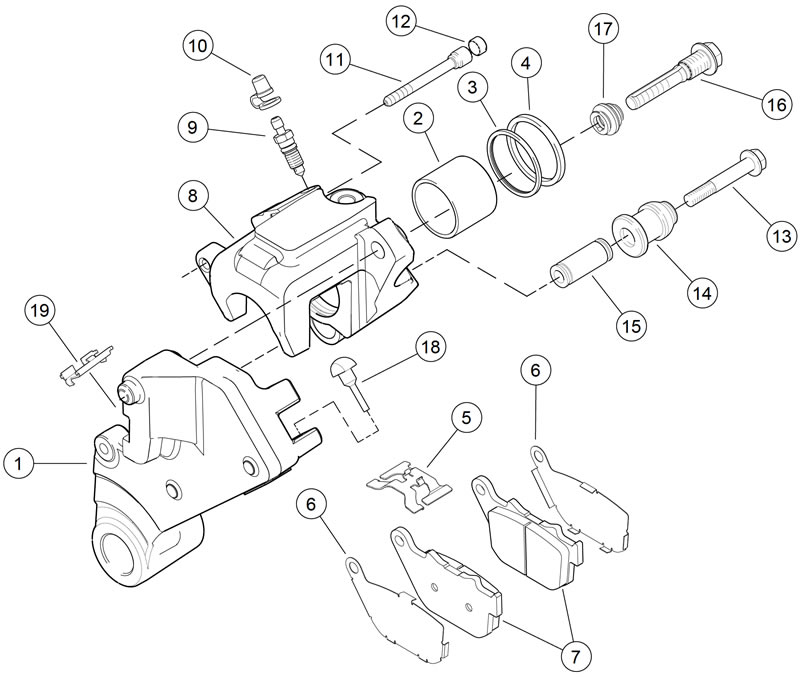

Figure 2-113. Rear brake caliper: XR 1200X: 1. Caliper mounting bracket; 2. Piston; 3. Dust seal; 4. Piston seal; 5. Pad spring; 6. Pad retainer; 7. Brake pad; 8. Caliper housing; 9. Bleeder valve; 10. Bleeder nipple cap; 11. Pad pin; 12. Pad pin plug; 13. Mounting bolt; 14. Boot; 15. Bushing; 16. Bolt pin; 17. Boot; 18. Damper; 19. Wear plate

Disassembly

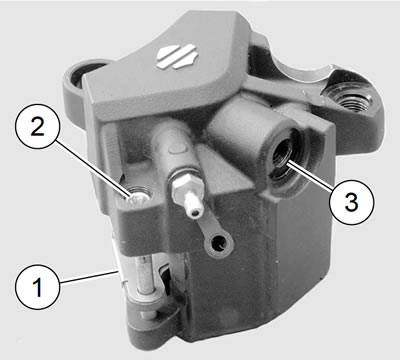

1. See Figure 2-114. Remove brake pad pin plug to expose brake pad pin (1). Remove brake pad pin and pads (2).

Figure 2-114. Pad pin: 1. Pad pin (plug removed); 2. Brake pad

2. See Figure 2-115. Remove pad spring (1).

Figure 2-115. Spring, bushing and boot: 1. Pad spring; 2. Bushing; 3. Boot; 4. Mounting hole

3. Remove bushing (2) from boot (3). Remove boot from mounting hole (4). Do not remove bleeder valve at this time.

4. See Figure 2-116. Install a discarded brake pad (1) in the caliper with the backing plate facing the piston. Position the brake pad so the friction material is against the back of the caliper, as shown.

Figure 2-116. Removing piston: XR 1200X: 1. Discarded brake pad; 2. Pad pin; 3. Banjo bolt hole

5. Loosely install brake pad pin (2) to hold brake pad in place.

Warning! Compressed air can pierce the skin and flying debris from compressed air could cause serious eye injury. Wear safety glasses when working with compressed air. Never use your hand to check for air leaks or to determine air flow rates.

Caution! When removing piston with compressed air, piston can develop considerable force and fly out of caliper bore. Keep hands away from piston to avoid possible injury.

Note. Do not damage banjo bolt sealing surface or threads of banjo bolt hole in brake caliper. Use an air nozzle with a rubber tip.

6. Gently apply low pressure compressed air to banjo bolt hole (3) to force piston from caliper bore.

7. Remove brake pad pin and brake pad from caliper.

8. Remove piston from caliper bore by hand. If necessary, gently wiggle piston to completely remove.

Note. A damaged piston bore will leak when reassembled. Do not use metal objects to remove or install components in piston bore. Prevent damage to piston, seal and bore by only using a wooden toothpick when servicing caliper.

9. See Figure 2-117. Using a wooden toothpick (1), remove dust seal (2) and piston seal (3) from caliper bore. Discard seals.

Figure 2-117. Caliper seals: 1. Wooden toothpick; 2. Dust seal; 3. Piston seal

10. If necessary, remove bleeder valve.

Cleaning, inspection and repair

Warning! Use denatured alcohol to clean brake system components. Do not use mineral-based solvents (such as gasoline or paint thinner), which will deteriorate rubber parts even after assembly. Deterioration of these components can cause brake failure, which could result in death or serious injury.

1. Clean piston bore with denatured alcohol.

2. Clean all rubber parts with DOT4 BRAKE FLUID. Do not contaminate with mineral oil or other solvents. Wipe parts dry with a clean, lint free cloth.

Warning! Compressed air can pierce the skin and flying debris from compressed air could cause serious eye injury. Wear safety glasses when working with compressed air. Never use your hand to check for air leaks or to determine air flow rates.

3. Blow out drilled passages and piston bore with low pressure compressed air from a clean air supply. Do not use a wire or similar instrument to clean drilled passages.

4. Carefully inspect all components. Replace any parts that appear damaged or worn.

- a. Check piston for pitting, scratching or corrosion on outside surfaces.

- b. Inspect caliper piston bore. Do not hone bore. If bore shows pitting or corrosion, replace caliper.

- c. Inspect pad pin for grooving and wear. Measure the pad pin diameter in an unworn area and then in the area of any grooving or wear. If wear is more than 0.011 in (0.28 mm), replace pad pin.

- d. Always replace all seals after disassembly.

5. Inspect bushing boot and bolt pin boot for deterioration or damage. Replace as necessary.

6. Inspect wear plate on caliper mount for wear. Replace as necessary.

Warning! Always replace brake pads in complete sets for correct and safe brake operation. Improper brake operation could result in death or serious injury.

7. Inspect brake pads and brake disc. Replace if necessary.

- a. See 1.17 BRAKE PADS AND DISCS: XR 1200X for specifications.

- b. See 2.5 WHEELS for brake disc replacement procedure.

Assembly

1. See Figure 2-118. If removed, install bushing boot (3) in caliper.

Figure 2-118. Assemble caliper: 1. Pad spring; 2. Bushing; 3. Boot

2. Apply approximately 0.4 g of G40M BRAKE GREASE inside caliper bushing boot (3).

3. Insert caliper bushing (2) into boot. Verify that the lips of boot are engaged in grooves at either end of bushing.

4. Install pad spring (1) in caliper housing. Verify that the spring is installed in the orientation shown.

Note. Use ONLY KS62F assembly grease for lubrication of internal brake parts. Use of DOT 4 brake fluid will result in increased brake pedal travel.

5. Lubricate the following parts prior to assembly using a light coat of KS62F assembly grease from the service parts kit. All other surfaces must be dry for assembly.

- a. Nose radius of piston.

- b. All surfaces of piston seal and dust seal.

Note. A damaged piston bore will leak when reassembled. Do not use metal objects to remove or install components in piston bore. Prevent damage to bore by only using a wooden toothpick when servicing caliper.

6. See Figure 2-119. Install a new piston seal (3) and a new dust seal (2) into piston bore.

Figure 2-119. Caliper seals: 1. Wooden toothpick; 2. Dust seal; 3. Piston seal

7. Carefully insert piston by hand, nose radius first, into caliper bore. If installation shows resistance, remove piston and check that seals are properly installed and fully seated in grooves.

8. Install bleeder valve if removed. Do not tighten bleeder valve at this time.

Installation

| FASTENER | TORQUE VALUE | |

| Rear caliper pin bolt | 14-18 ft·lbs | 19.6-24.5 Nm |

| Rear caliper mounting bolt | 14-18 ft·lbs | 19.6-24.5 Nm |

| Brake line banjo bolt | 20-25 ft·lbs | 27.1-33.9 Nm |

| Shock absorber mounting bolt | 45-50 ft·lbs | 61-68 Nm |

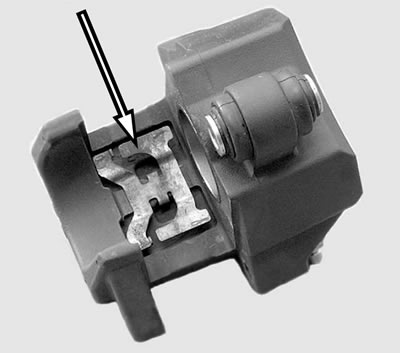

1. See Figure 2-120. If removed, install bolt pin boot (1).

Figure 2-120. Caliper mount: 1. Bolt pin boot; 2. Wear plate

2. Apply approximately 0.4 g of G40M BRAKE GREASE inside bolt pin boot.

3. If removed, install wear plate (2) on mounting bracket.

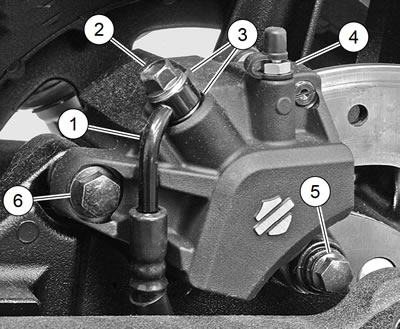

4. See Figure 2-121. Apply a drop of LOCTITE 272 HIGH STRENGTH/HIGH TEMPERATURE THREADLOCKER AND SEALANT (red/orange) to threads of bolt pin (6).

5. Place rear caliper assembly onto mounting bracket. Install bolt pin (6), being careful not to pinch or roll boot over.

6. See Figure 2-122. Verify that the lip of the boot (1) properly engages the groove (2) in the bolt pin.

Figure 2-122. Bolt pin and boot: 1. Boot; 2. Bolt pin groove

7. Tighten bolt pin to 14-18 ft·lbs (19.6-24.5 Nm).

8. See Figure 2-121. Install mounting bolt (5) and tighten to 14-18 ft·lbs (19.6-24.5 Nm).

Figure 2-121. Rear caliper assembly: 1. Rear brake line; 2. Banjo bolt; 3. Washer (2); 4. Bleeder valve; 5. Mounting bolt; 6. Bolt pin

Note. Brake caliper housing has a positive stop for banjo fitting. When tightening banjo bolt into brake caliper in the next step, rotate banjo fitting clockwise until it contacts positive stop.

9. Position a new washer (3) on each side of hydraulic brake line (1) banjo fitting. Insert banjo bolt (2) through washers and fitting and thread bolt into caliper housing. Tighten to 20-25 ft·lbs (27.1-33.9 Nm).

10. Install brake pads. See 1.17 BRAKE PADS AND DISCS: XR 1200X, Brake Pad Replacement: Rear.

11. Secure lower end of shock absorber to rear fork. Tighten to 45-50 ft·lbs (61-68 Nm).

12. Adjust drive belt and check vehicle alignment. See 1.24 WHEEL ALIGNMENT.

Caution! Direct contact of DOT 4 brake fluid with eyes can cause irritation. Avoid eye contact. In case of eye contact flush with large amounts of water and get medical attention. Swallowing large amounts of DOT 4 brake fluid can cause digestive discomfort. If swallowed, obtain medical attention. Use in well ventilated area. KEEP OUT OF REACH OF CHILDREN.

Notice: DOT 4 brake fluid will damage painted and body panel surfaces it comes in contact with. Always use caution and protect surfaces from spills whenever brake work is performed. Failure to comply can result in cosmetic damage.

Notes:

- If DOT 4 BRAKE FLUID contacts painted surfaces, IMMEDIATELY flush area with clear water.

- Rear brake master cylinder reservoir must be in a level position when filling and checking fluid level.

13. Remove rear brake master cylinder reservoir cap. Add DOT4 BRAKE FLUID to reservoir until fluid reaches upper fluid level (3). Do not overfill reservoir. Do not reuse brake fluid.

14. Bleed brake system. See 2.17 BLEEDING BRAKES.

Warning! A plugged or covered relief port can cause brake drag or lock-up, which could lead to loss of control, resulting in death or serious injury.

15. Verify proper operation of master cylinder relief port.

- a. Press against rear brake caliper to push caliper piston back into its bore. This pushes brake fluid back through master cylinder and verifies that relief port is not plugged.

- b. Pump brake pedal until caliper piston pushes pads against disc and pressure is returned to brake system.

16. Add DOT4 BRAKE FLUID to reservoir until fluid reaches upper fluid level.

Warning! After servicing brakes and before moving motorcycle, pump brakes to build brake system pressure. Insufficient pressure can adversely affect brake performance, which could result in death or serious injury.

Warning! After repairing the brake system, test brakes at low speed. If brakes are not operating properly, testing at high speeds can cause loss of control, which could result in death or serious injury.

17. Test brake system.

- a. Turn ignition switch ON. Pump brake pedal to verify operation of stop lamp.

- b. Test ride motorcycle at low speed. If brakes feel spongy, bleed system again. See 2.17 BLEEDING BRAKES.

Note. Avoid making hard stops for the first 100 mi (160 km). This allows the new pads to become conditioned to the brake discs.