General

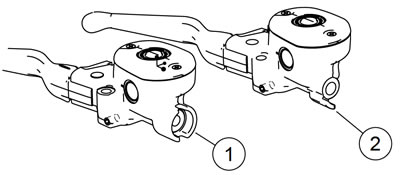

The front brake master cylinder designed for dual disc (two caliper) operation has a larger bore than the master cylinder designed for single disc (one caliper) operation.

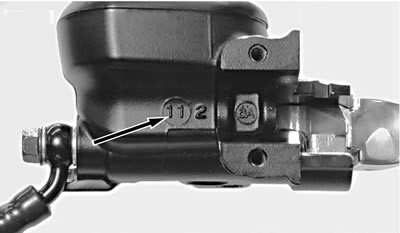

See Figure 2-48. The bore size is cast into the side of the master cylinder body facing the handlebar.

Figure 2-48. Verifying front brake master cylinder bore size (single disc master cylinder)

The single disc master cylinder has "11" (11 mm) cast into the body.

The dual disc master cylinder has "1/2" (1/2 in) cast into the body.

Note. Use only CCI #20 BRAKE GREASE to lubricate master cylinder bores, pistons, primary cups and secondary cups. Use only KS62F assembly grease on caliper pistons and piston seals. Use only G40M BRAKE GREASE on the caliper pins and boots, brake lever pivot hole, and the end of the piston that contacts the brake lever.

Warning! Do not use parts from single caliper repair kits (9/16 inch bore) on dual caliper models. Likewise, do not use parts from dual caliper repair kits (11/16 inch bore) on single caliper models. Using incorrect parts can cause brake failure, which could result in death or serious injury.

Notice: DOT 4 brake fluid will damage painted and body panel surfaces it comes in contact with. Always use caution and protect surfaces from spills whenever brake work is performed. Failure to comply can result in cosmetic damage.

Note. If DOT 4 BRAKE FLUID contacts painted surfaces, IMMEDIATELY flush area with clear water.

Inspection

1. Check the fluid level in the front brake reservoir. Ifit is low, refill and bleed brake system. See 2.17 BLEEDING BRAKES.

2. Check for fluid leaks in the brake line, around banjo fittings or front brake caliper pistons or bleeder valve. Repair and bleed brake system.

- a. For brake line replacement procedure, see 2.16 BRAKE LINES.

- b. To repair front brake caliper, see procedure in 2.9 FRONT BRAKE CALIPER: XL MODELS or 2.10 FRONT BRAKE CALIPER: XR 1200X.

- c. See 2.17 BLEEDING BRAKES for hydraulic brake system bleeding procedure.

3. Check front brake friction pads and disc(s) for excessive wear or damage. Replace if necessary.

- a. See 1.16 BRAKE PADS AND DISCS: XL MODELS or 1.17 BRAKE PADS AND DISCS: XR 1200X for specifications and brake pad replacement procedure.

- b. See 2.5 WHEELS for brake disc replacement procedure.

4. Eliminate any air in the hydraulic brake assembly by bleeding the system. See 2.17 BLEEDING BRAKES.

If none of these conditions exist but the front brake system does not operate properly, the front brake master cylinder is defective. Repair or replace if necessary.

Removal

1. See Figure 2-49. Loosen turn signal clamp screw (3) and remove turn signal assembly (5) from front brake master cylinder housing (1).

2. Remove locknut, washer (4) and mirror (2) from master cylinder housing.

Figure 2-49. Front brake master cylinder (typical): 1. Front brake master cylinder and reservoir; 2. Mirror; 3. Turn signal clamp screw; 4. Locknut and washer; 5. Turn signal assembly; 6. Front brake banjo fitting; 7. Banjo bolt; 8. Sealing washer

Caution! Direct contact of DOT 4 brake fluid with eyes can cause irritation. Avoid eye contact. In case of eye contact flush with large amounts of water and get medical attention. Swallowing large amounts of DOT 4 brake fluid can cause digestive discomfort. If swallowed, obtain medical attention. Use in well ventilated area. KEEP OUT OF REACH OF CHILDREN.

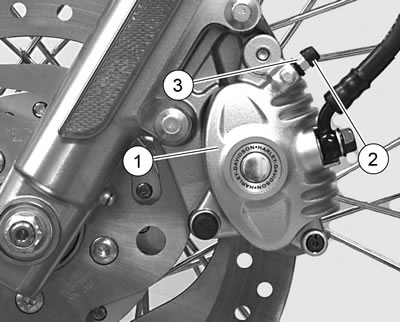

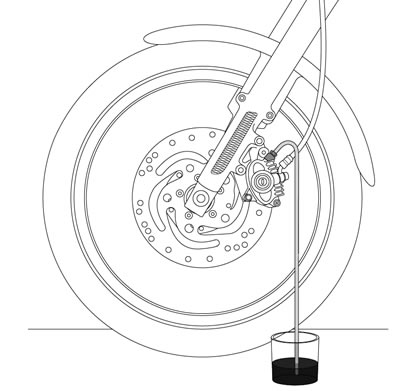

3. See Figure 2-50 and Figure 2-51. Drain brake fluid:

- a. Remove bleeder nipple cap (2) from bleeder valve (3) on front brake caliper (1).

- b. Install a length of 5/16 in (7.9 mm) ID clear plastic tubing over caliper bleeder valve (3). Place free end in a suitable container.

- c. Open bleeder valve about 1/2 turn.

- d. Pump brake hand lever several times to drain brake fluid.

- e. Close bleeder valve.

Figure 2-50. Front caliper bleeder valve (typical): 1. Front brake caliper; 2. Bleeder nipple cap; 3. Bleeder valve

Figure 2-51. Bleeding hydraulic system

Note. Dispose of brake fluid in accordance with local regulations.

4. See Figure 2-49. Remove banjo bolt (7) and two washers (8) to disconnect front brake line banjo fitting (6) from master cylinder (1). Discard washers.

5. See Figure 2-52. Squeeze front brake lever and place a 5/32 in (4 mm) thick cardboard insert between brake lever and lever bracket. Release brake lever.

Figure 2-52. Install cardboard insert before removing master cylinder assembly

Notice: Do not remove or install the master cylinder assembly without first positioning a 5/32-inch (4 mm) thick insert between the brake lever and lever bracket. Removing or installing the master cylinder assembly without the insert in place may result in damage to the rubber boot and plunger on the front stoplight switch.

Note. Use the eyelet of an ordinary cable strap if the cardboard insert is not available.

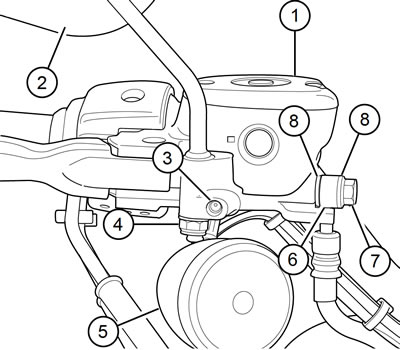

6. See Figure 2-53. Remove the two screws (6) and washers (7) securing the handlebar clamp (8) to the master cylinder housing (5). Remove the brake lever/master cylinder assembly and clamp from the handlebar.

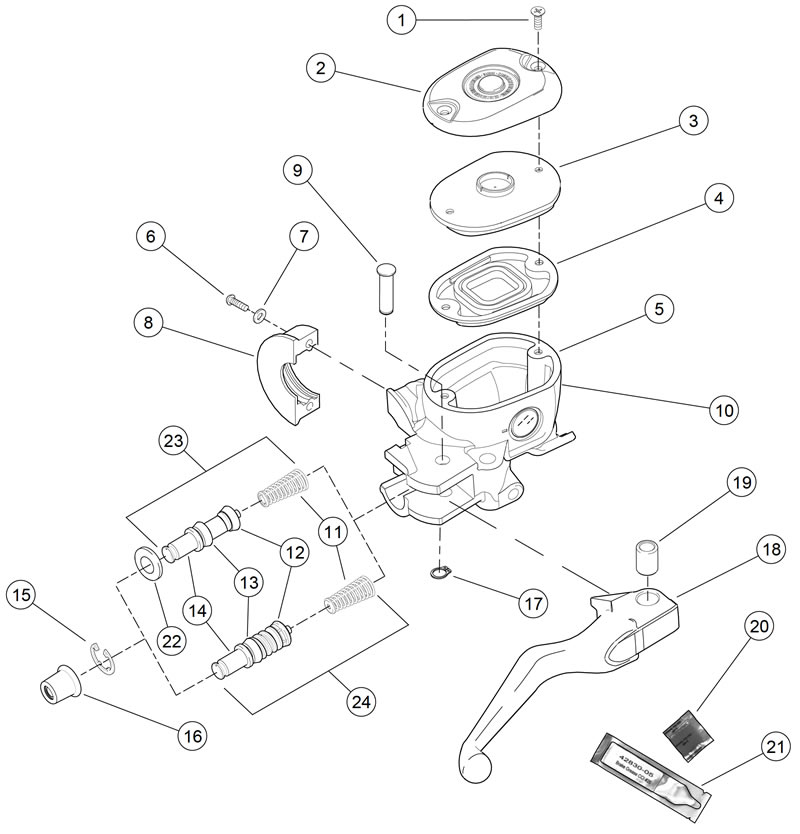

Figure 2-53. Front brake master cylinder assembly (*provided in service parts kit): 1. Screw (2); 2. Reservoir cover; 3. Diaphragm plate; 4. Diaphragm; 5. Master cylinder housing; 6. Screw (2); 7. Washer (2); 8. Handlebar clamp; 9. Pivot pin; 10. Brake line banjo fitting seating surface; 11. Spring*; 12. Primary cup*; 13. Secondary cup*; 14. Piston*; 15. Retaining ring*; 16. Dust boot*; 17. Retaining ring; 18. Brake hand lever; 19. Bushing; 20. G40M brake grease*; 21. CCI #20 brake grease*; 22. Stop plate (single disc piston only)*; 23. Single disc piston assembly; 24. Dual disc piston assembly

Disassembly

Warning! Wear safety glasses or goggles when removing or installing retaining rings. Retaining rings can slip from the pliers and could be propelled with enough force to cause serious eye injury.

Note. Use correct retaining ring pliers and correct tips. Verify that tips are not excessively worn or damaged.

1. See Figure 2-53. Remove retaining ring (17) from pivot pin (9) groove at bottom of master cylinder bracket. Discard retaining ring.

2. Remove pivot pin and brake hand lever (18) from master cylinder assembly.

3. Remove and discard dust boot (16).

Note. See Figure 2-54. Clamp front brake master cylinder in a vise by the mirror mounting boss only. Use brass or aluminum jaw covers or other protective device on vise jaws to prevent damage to master cylinder.

4. See Figure 2-54. Clamp master cylinder in a vise so that banjo fitting hole is pointing straight down.

Figure 2-54. Clamping front master cylinder

Warning! Wear safety glasses or goggles when removing or installing retaining rings. Retaining rings can slip from the pliers and could be propelled with enough force to cause serious eye injury.

5. See Figure 2-53. Press down on end of piston and remove retaining ring (15). Discard retaining ring.

6. Single disc piston assembly: remove stop plate (22).

7. Remove and discard piston assembly (12, 13, 14) and piston spring (11).

Notes:

- See Figure 2-53. Both primary (12) and secondary (13) cups are fitted into grooves in the piston body (14). The piston spring (11) fits onto the end of the piston.

- Always clean the cover before removal. This prevents dirt and other contaminants from entering the master cylinder reservoir.

8. Remove two screws (1), cover (2), diaphragm plate (3) and diaphragm (4) from the master cylinder reservoir.

Cleaning, inspection and repair

Warning! Compressed air can pierce the skin and flying debris from compressed air could cause serious eye injury. Wear safety glasses when working with compressed air. Never use your hand to check for air leaks or to determine air flow rates.

Note. Do notuse a wire orsimilarinstrumentto clean drilledpassages in bottom ofreservoir.

1. Clean brake system components with denatured alcohol. Do not contaminate with mineral oil or other solvents.

- a. Wipe dry with a clean, lint free cloth.

- b. Blow out drilled passages and piston bore with low pressure compressed air from a clean air supply.

Warning! Use denatured alcohol to clean brake system components. Do not use mineral-based solvents (such as gasoline or paint thinner), which will deteriorate rubber parts even after assembly. Deterioration of these components can cause brake failure, which could result in death or serious injury.

2. Carefully inspect all parts for wear or damage. Replace as necessary.

- a. Inspect the piston bore in the master cylinder housing for scoring, pitting or corrosion.

- b. Inspect the outlet port that mates with the brake line banjo fitting. This is a critical sealing surface.

- c. Inspect diaphragm for damage.

Assembly

Warning! Do not use parts from single caliper repair kits (9/16 inch bore) on dual caliper models. Likewise, do not use parts from dual caliper repair kits (11/16 inch bore) on single caliper models. Using incorrect parts can cause brake failure, which could result in death or serious injury.

Notes:

- Always reassemble the master cylinder using new parts from the correct service repair kit.

- CCI #20 BRAKE GREASE is recommended for lubrication of cylinder bore, cups and seals prior to assembly.

- See Figure 2-54. Clamp front brake master cylinder in a vise by the mirror mounting boss only. Use brass or aluminum jaw covers or other protective device on vise jaws to prevent damage to master cylinder.

1. See Figure 2-54. Clamp master cylinder in a vise so that banjo fitting hole is pointing straight down.

2. See Figure 2-53. Coat piston bore of master cylinder housing (5), piston (14), primary cup (12) and secondary cup (13) with CCI #20 BRAKE GREASE (21) supplied in the service parts kit.

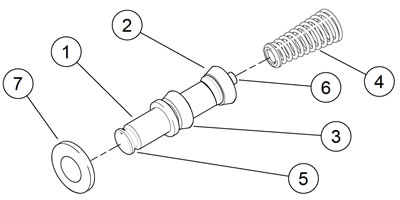

3. See Figure 2-55. Install piston assembly into master cylinder.

- a. Press small end of piston spring (4) onto mounting boss (6) on piston (1).

- b. Slide piston/spring assembly, flared end ofspring first, into master cylinder bore so that spring seats against counter bore (recess) at bottom of cylinder.

- c. Single disc piston: Slide stop plate (7) down over end of piston.

Figure 2-55. Front brake master cylinder piston (typical-single disc piston shown): 1. Piston; 2. Primary cup; 3. Secondarycup; 4. Piston spring; 5. Dust boot groove; 6. Piston spring mounting boss; 7. Stop plate (single disc piston only)

Warning! Wear safety glasses or goggles when removing or installing retaining rings. Retaining rings can slip from the pliers and could be propelled with enough force to cause serious eye injury.

Note. Use correct retaining ring pliers and correct tips. Verify that tips are not excessively worn or damaged.

4. See Figure 2-53.

- a. Dual disc master cylinder: Press down on piston (14) and install new retaining ring (15). Verify that retaining ring is fully seated in groove.

- b. Single disc master cylinder: Press down on piston (14) and stop plate (22), and install new retaining ring (15). Verify that retaining ring is fully seated in groove.

5. Install new dust boot (16). Large lip of dust boot fits down inside end of piston bore. Small lip of dust boot fits into groove in end of piston (item 5, Figure 2-55).

6. Apply approximately 0.1 g G40M BRAKE GREASE (from service parts kit) to each of the following two locations:

- a. Pivot hole in brake hand lever (18).

- b. End of piston (14).

7. Align hole in brake hand lever with hole in master cylinder bracket. From top of assembly, slide pivot pin (9) through bracket and hand lever.

Warning! Wear safety glasses or goggles when removing or installing retaining rings. Retaining rings can slip from the pliers and could be propelled with enough force to cause serious eye injury.

8. Install new retaining ring (17) in pivot pin groove. Verify that retaining ring is fully seated in groove.

9. Remove master cylinder assembly from vise. Install cover (2), diaphragm plate (3) and diaphragm (4) on master cylinder reservoir. Install two screws (1) to fasten cover to reservoir, but do not tighten at this time.

10. See Figure 2-56. Squeeze front brake lever and place a 5/32 in (4 mm) thick cardboard insert between brake lever and lever bracket. Release brake lever.

Figure 2-56. Install 5/32 in (4 mm) cardboard insert before installing master cylinder assembly

Installation

| FASTENER | TORQUE VALUE | |

| Brake master cylinder clamp, front, screw | 108-132 in·lbs | 12.2-14.9 Nm |

| Brake line banjo bolt | 20-25 ft·lbs | 27.1-33.9 Nm |

| Mirror stem locknut | 96-144 in·lbs | 10.9-16.3 Nm |

| Cylinder head exhaust port nut | 96-120 in·lbs | 10.9-13.6 Nm |

Notice: Do not remove or install the master cylinder assembly without first positioning a 5/32-inch (4 mm) thick insert between the brake lever and lever bracket. Removing or installing the master cylinder assembly without the insert in place may result in damage to the rubber boot and plunger on the front stoplight switch.

1. See Figure 2-57. Position brake lever/master cylinder assembly inboard of switch housing assembly (1). Engage tab (5) on lower switch housing in slot (4) at top of brake lever bracket (3).

Figure 2-57. Fitting brake lever/master cylinder to right handlebar switch housing: 1. Switch housing assembly; 2. 5/32 in (4 mm) cardboard insert; 3. Brake lever bracket; 4. Slot; 5. Tab

2. See Figure 2-53. Align holes in handlebar clamp (8) with master cylinder housing (5). Start two screws (6) with washers (7). Beginning with top screw, tighten to 108-132 in·lbs (12.2-14.9 Nm).

Notice: Avoid leakage. Be sure gaskets, banjo bolt(s), brake line and master cylinder bore are clean and undamaged before assembly.

Note. See Figure 2-58. The master cylinder housing positive stops for banjo fittings are different on XL Models and the XR 1200X. Never intermix model components. When tightening the banjo bolt, verify that the banjo fitting is correctly oriented and contacts the positive stop.

Figure 2-58. Front brake master cylinder identification: 1. XR 1200X; 2. XL models

3. See Figure 2-59. Position a new washer (8) on each side of hydraulic brake line banjo fitting (6). Insert banjo bolt (7) through washers and fitting. Thread bolt into master cylinder housing. Tighten to 20-25 ft·lbs (27.1-33.9 Nm).

Figure 2-59. Front brake mastercylinder (typical): 1. Front brake master cylinder and reservoir; 2. Mirror; 3. Turn signal clamp screw; 4. Locknut and washer; 5. Turn signal assembly; 6. Front brake banjo fitting; 7. Banjo bolt; 8. Sealing washer

4. See Figure 2-53. Position motorcycle so that top of master cylinder reservoir is level. Remove two screws (1), front master cylinder reservoir cover (2), diaphragm plate (3) and diaphragm (4).

Caution! Direct contact of DOT 4 brake fluid with eyes can cause irritation. Avoid eye contact. In case of eye contact flush with large amounts of water and get medical attention. Swallowing large amounts of DOT 4 brake fluid can cause digestive discomfort. If swallowed, obtain medical attention. Use in well ventilated area. KEEP OUT OF REACH OF CHILDREN.

Notice: DOT 4 brake fluid will damage painted and body panel surfaces it comes in contact with. Always use caution and protect surfaces from spills whenever brake work is performed. Failure to comply can result in cosmetic damage.

Notes:

- If DOT 4 brake fluid contacts painted surfaces, IMMEDIATELY flush area with clear water.

- Cover handlebar switches with a shop towel before adding brake fluid to front master cylinder reservoir. Spilling brake fluid on handlebar switches may render them inoperative.

- See Figure 2-60. Do not use sight glass (2) to determine maximum fluid level. Sight glass should only be used as a visual indicator that fluid level is low and needs attention.

- A ridge (1) is cast into the inside of the reservoir to help determine the correct maximum fluid level.

- Fill master cylinder only with DOT 4 BRAKE FLUID from a sealed container.

- Do not overfill reservoir. Do not reuse old brake fluid.

5. See Figure 2-60. Add enough DOT 4 BRAKE FLUID to reservoir to bring fluid level even with ridge (1) cast into inside of reservoir, about 1/4 in (6.35 mm) below top edge.

Figure 2-60. Filling front master cylinder reservoir: 1. Cast-in ridge; 2. Sight glass

Warning! A plugged or covered relief port can cause brake drag or lock-up, which could lead to loss of control, resulting in death or serious injury.

6. Verify proper operation of master cylinder relief port. Slowly actuate brake hand lever with reservoir cover removed. A slight spurt of fluid will break fluid surface in reservoir compartment if all internal components are working properly.

7. Bleed brake system. See 2.17 BLEEDING BRAKES.

Note. On dual caliper models, bleed both calipers.

Warning! After repairing the brake system, test brakes at low speed. If brakes are not operating properly, testing at high speeds can cause loss of control, which could result in death or serious injury.

8. See Figure 2-59. Install mirror (2), secure with locknut and washer (4). Position mirror for rearward visibility. Tighten locknut to 96-144 in·lbs (10.9-16.3 Nm).

Note. XL 1200X: Install mirror upside down. Check clearance between mirrors and gas tank while turning handlebar lock to lock.

9. All Models except XL 1200X: Install turn signal assembly (5). Position so lens faces directly forward. Verify turn signal does not strike fuel tank when the handlebar is turned full right. Tighten clamp screw (3) to 96-120 in·lbs (10.9-13.6 Nm).

10. Verify operation of stop lamp.

Warning! After repairing the brake system, test brakes at low speed. If brakes are not operating properly, testing at high speeds can cause loss of control, which could result in death or serious injury.

11. Test brake system.

- a. Test ride motorcycle at low speed. If brake feels spongy, repeat bleeding procedure.

- b. Test ride the motorcycle. If the brakes feel spongy, bleed the system again. See 2.17 BLEEDING BRAKES.