Warning! Check that all components are in perfect condition. Inspect the following components with special care.

Bearings

Rotate the inner ring (1) manually. The ring should turn smoothly, with no hardness or noise.

There should be no end float.

Replace any bearings that do not meet the above requirements.

Seals

Inspect the seals and replace if damaged or badly worn.

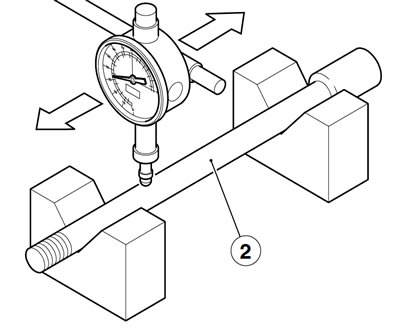

Wheel spindle

Check spindle (2) run-out using a dial gauge. Replace the spindle (2) when run-out exceeds the maximum limit allowed.

Wheel spindle run-out limit: 0.25 mm.

Wheel rim

Use a dial gauge to ensure that wheel rim (3) radial (A) and axial (B) run-out does not exceed the maximum limit allowed.

Exceeding run-out is normally due to worn or damaged bearings.

Replace the bearings first, then check run-out again.

Replace the wheel rim (3) if it still exceeds the maximum limit allowed.

Wheel rim radial and axial run-out limit: 2 mm.

Tyre

Check tyre condition; see 2.19.1.