Torque wrench settings:

- Wheel spindle nut (7): 100 Nm (10.0 kg·m).

Warning!

- To avoid the risk of burns, allow the engine and silencer to cool down completely before proceeding.

- Use great care on refitting, to avoid damage to the brake line, brake disc and brake pads.

Grease the outer seating areas of the wheel hub moderately.

Note. Ensure that the left-hand (1) and right-hand (2) spacers do not get mixed up. Refit each spacer in its original position.

Fit the left-hand (1) and right-hand (2) spacers, each in its location on the wheel hub.

Warning!

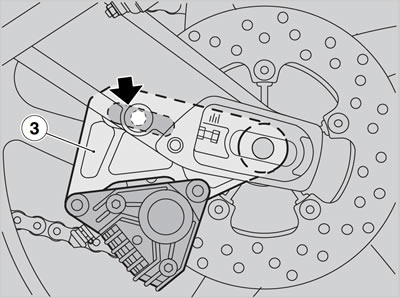

- Before proceeding to reassemble, check that the caliper carrier (3) is positioned correctly. The carrier slot must be sitting on the locating peg found on the inboard face of the left swinging arm.

- Be careful when locating the brake disc to the caliper.

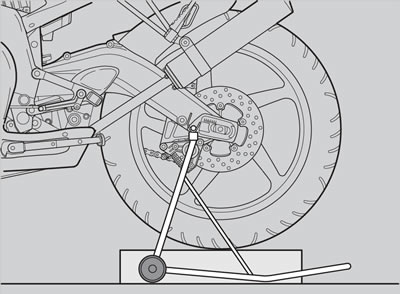

Place the wheel between the swinging arms above the support.

Danger! Do not put your fingers between chain and chain sprocket.

Push the wheel forward and wrap the chain around the rear chain sprocket.

Pull the wheel backwards until the centre hole matches the swinging arm holes.

Note. Ensure that the right-hand (4) and left-hand (5) tensioners do not get mixed up. Refit each tensioner in its original position.

Locate the right-hand chain tensioner (4) and the lefthand chain tensioner (5) to the swinging arm at the correct positions.

Smear a light coat of grease evenly on the wheel spindle (6).

Push the wheel spindle (6) fully home from the left side.

Note. Make sure the wheel spindle (6) is fully in with the head fully seated into the left-hand chain tensioner (5).

Fit the washer and screw the nut (7) hand tight.

Check chain slack; see 2.21.1.

Tighten the nut (7).

Warning!

- After After reassembling, operate the rear brake lever repeatedly and checkfor proper operation of the brake.

- Ensure that the wheel is perfectly centred.