Engine fuel supply system of motorcycle Kawasaki VN900 Vulcan (2006-2024)

See this section in russian language

Fuel system (DFI) exploded view

No. Fastener Torque Remarks N·m kgf·m ft·lb 1 Fuel Pump Bolts 9.8 1.0 87 in·lb L 2 Air Cleaner Housing Bolts 9.8 1.0 87 in·lb 3 Air Cleaner Cover Bolts 4.9 0.50 43 in·lb 4 Throttle Body Assy Holder Bolts 9.8 1.0 87 in·lb 5 Inlet Manifold Bolts 9.8...

No. Fastener Torque Remarks N·m kgf·m ft·lb 1 Fuel Pump Bolts 9.8 1.0 87 in·lb L 2 Air Cleaner Housing Bolts 9.8 1.0 87 in·lb 3 Air Cleaner Cover Bolts 4.9 0.50 43 in·lb 4 Throttle Body Assy Holder Bolts 9.8 1.0 87 in·lb 5 Inlet Manifold Bolts 9.8...

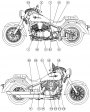

Fuel system parts location

1. Ignition Coil #1; 2. Fuel Pump; 3. Ignition Coil #2; 4. Main Fuse 30 A; 5. Relay Box; 6. Fuse Box; 7. Vehicle Down Sensor; 8. ECU; 9. Battery; 10. Crankshaft Sensor; 11. Injector #2; 12. Injector #1; 13. Water Temperature Sensor; 14. Main...

1. Ignition Coil #1; 2. Fuel Pump; 3. Ignition Coil #2; 4. Main Fuse 30 A; 5. Relay Box; 6. Fuse Box; 7. Vehicle Down Sensor; 8. ECU; 9. Battery; 10. Crankshaft Sensor; 11. Injector #2; 12. Injector #1; 13. Water Temperature Sensor; 14. Main...

Fuel system specifications

Item Standard Throttle Grip Free Play 2 - 3 mm (0.08 - 0.12 in.) Air Cleaner Element Viscous paper element DFI System Make Denso Idle Speed 1 000±50 r/min (rpm) Throttle Body Assy: Type x Bore Two barrel type x ∅34 mm (1.34 in.) ECU (Electronic...

Item Standard Throttle Grip Free Play 2 - 3 mm (0.08 - 0.12 in.) Air Cleaner Element Viscous paper element DFI System Make Denso Idle Speed 1 000±50 r/min (rpm) Throttle Body Assy: Type x Bore Two barrel type x ∅34 mm (1.34 in.) ECU (Electronic...

Special tools and sealant

Oil Pressure Gauge, 5 kgf/cm²: 57001-125 Needle Adapter Set: 57001-1457 Fork Oil Level Gauge: 57001-1290 Fuel Pressure Gauge Adapter: 57001-1593 Hand Tester: 57001-1394 Fuel Hose: 57001-1607 Peak Voltage Adapter: 57001-1415 Speed Sensor Measuring...

Oil Pressure Gauge, 5 kgf/cm²: 57001-125 Needle Adapter Set: 57001-1457 Fork Oil Level Gauge: 57001-1290 Fuel Pressure Gauge Adapter: 57001-1593 Hand Tester: 57001-1394 Fuel Hose: 57001-1607 Peak Voltage Adapter: 57001-1415 Speed Sensor Measuring...

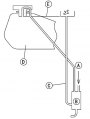

Description of DFI system

1. Battery; 2. ECU; 3. Injector; 4. Fuel Pump; 5. Fuel Tank; 6. Subthrottle Valve Actuator; 7. Air Cleaner; 8. Subthrottle Sensor; 9. Main Throttle Sensor; 10. Inlet Air Temperature Sensor; 11. Water Temperature Sensor; 12. Inlet Air Pressure...

1. Battery; 2. ECU; 3. Injector; 4. Fuel Pump; 5. Fuel Tank; 6. Subthrottle Valve Actuator; 7. Air Cleaner; 8. Subthrottle Sensor; 9. Main Throttle Sensor; 10. Inlet Air Temperature Sensor; 11. Water Temperature Sensor; 12. Inlet Air Pressure...

DFI servicing precautions

There are a number of important precautions that should be followed servicing the DFI system. This DFI system is designed to be used with a 12 V sealed battery as its power source. Do not use any other battery except for a 12 V sealed battery as a...

There are a number of important precautions that should be followed servicing the DFI system. This DFI system is designed to be used with a 12 V sealed battery as its power source. Do not use any other battery except for a 12 V sealed battery as a...

Troubleshooting the DFI system

Outline When an abnormality in the system occurs, the FI indicator LED (Light Emitting Diode) light goes on to alert the rider on the meter panel. In addition, the condition of the problem is stored in the memory of the ECU (electronic control...

Outline When an abnormality in the system occurs, the FI indicator LED (Light Emitting Diode) light goes on to alert the rider on the meter panel. In addition, the condition of the problem is stored in the memory of the ECU (electronic control...

DFI system troubleshooting guide

Notes: This is not an exhaustive list, giving every possible cause for each problem listed. It is meant simply as a rough guide to assist the troubleshooting for some of the more common difficulties. The ECU may be involved in the DFI electrical and...

Notes: This is not an exhaustive list, giving every possible cause for each problem listed. It is meant simply as a rough guide to assist the troubleshooting for some of the more common difficulties. The ECU may be involved in the DFI electrical and...

Fuel system self-diagnosis

Self-diagnosis outline The self-diagnosis system has three modes and can be switched to another mode by grounding the self-diagnosis terminal. User Mode The ECU notifies the rider of troubles in DFI system and ignition system by lighting the FI...

Self-diagnosis outline The self-diagnosis system has three modes and can be switched to another mode by grounding the self-diagnosis terminal. User Mode The ECU notifies the rider of troubles in DFI system and ignition system by lighting the FI...

Main throttle sensor (service code 11)

The main throttle sensor is a rotating variable resistor that change output voltage according to throttle operating. The ECU senses this voltage change and determines fuel injection quantity, and ignition timing according to engine rpm, and throttle...

The main throttle sensor is a rotating variable resistor that change output voltage according to throttle operating. The ECU senses this voltage change and determines fuel injection quantity, and ignition timing according to engine rpm, and throttle...

Inlet air pressure sensor (service code 12)

Inlet air pressure sensor removal Caution! Never drop the sensor, especially on a hard surface. Such a shock to the part can damage it. Remove: Fuel Tank (see Fuel tank removal ) Bolt [A] Disconnect the inlet air pressure sensor connector [B], and...

Inlet air pressure sensor removal Caution! Never drop the sensor, especially on a hard surface. Such a shock to the part can damage it. Remove: Fuel Tank (see Fuel tank removal ) Bolt [A] Disconnect the inlet air pressure sensor connector [B], and...

Inlet air temperature sensor (service code 13)

Inlet air temperature sensor removal/installation Caution! Never drop the sensor, especially on a hard surface. Such a shock to the sensor can damage it. Remove the air cleaner housing (see Air cleaner housing removal ). Remove the screw [A]. Pull...

Inlet air temperature sensor removal/installation Caution! Never drop the sensor, especially on a hard surface. Such a shock to the sensor can damage it. Remove the air cleaner housing (see Air cleaner housing removal ). Remove the screw [A]. Pull...

Water temperature sensor (service code 14)

Removal/installation Caution! Never drop the sensor, especially on a hard surface. Such a shock to the sensor can damage it. Remove the fuel tank (see Fuel tank removal ). Drain the coolant (see Coolant change in the Periodic Maintenance chapter)....

Removal/installation Caution! Never drop the sensor, especially on a hard surface. Such a shock to the sensor can damage it. Remove the fuel tank (see Fuel tank removal ). Drain the coolant (see Coolant change in the Periodic Maintenance chapter)....

Crankshaft sensor (service code 21)

Start the engine and switch the diagnosis mode to Dealer 1 mode to know all the problem that the DFI system has at the time of self-diagnosis. If the engine cannot be started, the self-diagnosis system does not detect dynamic condition of the...

Start the engine and switch the diagnosis mode to Dealer 1 mode to know all the problem that the DFI system has at the time of self-diagnosis. If the engine cannot be started, the self-diagnosis system does not detect dynamic condition of the...

Speed sensor (service code 24, 25)

Speed sensor removal Refer to the Speed sensor removal in the Electrical System chapter. Speed sensor installation Refer to the Speed sensor installation in the Electrical System chapter. Speed sensor inspection Refer to the Speed sensor inspection...

Speed sensor removal Refer to the Speed sensor removal in the Electrical System chapter. Speed sensor installation Refer to the Speed sensor installation in the Electrical System chapter. Speed sensor inspection Refer to the Speed sensor inspection...

Vehicle-down sensor (service code 31)

Vehicle-down sensor removal Remove: Tool Box (see Tool box removal in the Frame chapter) Bolts [A] Vehicle-down Sensor [B] Connector [C] (disconnect) Vehicle-down sensor installation Install the vehicle-down sensor [A] in the original position. The...

Vehicle-down sensor removal Remove: Tool Box (see Tool box removal in the Frame chapter) Bolts [A] Vehicle-down Sensor [B] Connector [C] (disconnect) Vehicle-down sensor installation Install the vehicle-down sensor [A] in the original position. The...

Subthrottle sensor (service code 32)

The subthrottle sensor is a rotating variable resistor that change output voltage according to throttle operating. The ECU senses this voltage change and determines fuel injection quantity, and ignition timing according to engine rpm, and throttle...

The subthrottle sensor is a rotating variable resistor that change output voltage according to throttle operating. The ECU senses this voltage change and determines fuel injection quantity, and ignition timing according to engine rpm, and throttle...

Oxygen sensor — not activated (#1, #2: service code 33, 83) — Europe models

Oxygen Sensor #1: Service Code 33 Oxygen Sensor #2: Service Code 83 Oxygen sensor removal/installation Refer to Oxygen sensor removal and installation in the Electrical System chapter. Oxygen sensor inspection Note. The oxygen sensor itself is the...

Oxygen Sensor #1: Service Code 33 Oxygen Sensor #2: Service Code 83 Oxygen sensor removal/installation Refer to Oxygen sensor removal and installation in the Electrical System chapter. Oxygen sensor inspection Note. The oxygen sensor itself is the...

Ignition coils (#1, #2: service code 51, 52)

Ignition Coil #1: Ignition Coil for Front Cylinder (Service Code 51) Ignition Coil #2: Ignition Coil for Rear Cylinder (Service Code 52) Ignition coil removal/installation Caution! Never drop the ignition coils, especially on a hard surface. Such a...

Ignition Coil #1: Ignition Coil for Front Cylinder (Service Code 51) Ignition Coil #2: Ignition Coil for Rear Cylinder (Service Code 52) Ignition coil removal/installation Caution! Never drop the ignition coils, especially on a hard surface. Such a...

Radiator fan relay (service code 56)

Radiator fan relay removal/installation Radiator fan relay is bult in the relay box. Remove the relay box (see Relay box removal in the Electrical System chapter). Radiator fan relay inspection Refer to the Relay circuit inspection in the Electrical...

Radiator fan relay removal/installation Radiator fan relay is bult in the relay box. Remove the relay box (see Relay box removal in the Electrical System chapter). Radiator fan relay inspection Refer to the Relay circuit inspection in the Electrical...

Subthrottle valve actuator (service code 62)

Subthrottle valve actuator removal Caution! Do not remove the subthrottle valve actuator [A] since it has been adjusted and set with precision at the factory. Never drop the actuator, especially on a hard surface. Such a shock to the actuator can...

Subthrottle valve actuator removal Caution! Do not remove the subthrottle valve actuator [A] since it has been adjusted and set with precision at the factory. Never drop the actuator, especially on a hard surface. Such a shock to the actuator can...

Air switching valve (service code 64)

Air switching valve removal/installation see Clean air system section in the Engine Top End chapter. Air switching valve inspection see Air switching valve unit test in the Electrical System chapter. Check the wiring continuity, using the following...

Air switching valve removal/installation see Clean air system section in the Engine Top End chapter. Air switching valve inspection see Air switching valve unit test in the Electrical System chapter. Check the wiring continuity, using the following...

Oxygen sensor heaters (#1, #2: service code 67) — Europe models

Oxygen sensor heater removal/installation The oxygen sensor heater is bult in the oxygen sensor. So, the heater itself can not be removed. Remove the oxygen sensor (see Switch and Sensors section in the Electrical System chapter). Oxygen sensor...

Oxygen sensor heater removal/installation The oxygen sensor heater is bult in the oxygen sensor. So, the heater itself can not be removed. Remove the oxygen sensor (see Switch and Sensors section in the Electrical System chapter). Oxygen sensor...

Oxygen sensors-incorrect output voltage (#1, #2: service code 94, 95) — Europe models

Oxygen Sensor #1: Service Code 94 Oxygen Sensor #2: Service Code 95 Oxygen sensor removal/installation Refer to Oxygen sensor removal and installation in the Electrical System chapter. Oxygen sensor inspection Note. The oxygen sensor itself is the...

Oxygen Sensor #1: Service Code 94 Oxygen Sensor #2: Service Code 95 Oxygen sensor removal/installation Refer to Oxygen sensor removal and installation in the Electrical System chapter. Oxygen sensor inspection Note. The oxygen sensor itself is the...

FI indicator LED light

Inspection flow chart LED light inspection The FI indicator LED light [A] goes ON when the ignition switch is turned ON and the LED light goes OFF when the engine oil pressure is high enough (the engine is running). This is to ensure that the FI...

Inspection flow chart LED light inspection The FI indicator LED light [A] goes ON when the ignition switch is turned ON and the LED light goes OFF when the engine oil pressure is high enough (the engine is running). This is to ensure that the FI...

ECU — removal and installation

ECU removal Caution! Never drop the ECU, especially on a hard surface. Such a shock to the ECU can damage it. Remove: Seat (see Seat removal in the Frame chapter) Tool Box (see Tool box removal in the Frame chapter) Pull out the ECU [A] along with...

ECU removal Caution! Never drop the ECU, especially on a hard surface. Such a shock to the ECU can damage it. Remove: Seat (see Seat removal in the Frame chapter) Tool Box (see Tool box removal in the Frame chapter) Pull out the ECU [A] along with...

ECU power supply inspection

Visually inspect the terminals of the ECU connector. ★ If the connector is clogged with mud or dust, blow it off with compressed air. ★ Replace the main harness if the terminals [A] of the main harness connectors are cracked, bent, or otherwise...

Visually inspect the terminals of the ECU connector. ★ If the connector is clogged with mud or dust, blow it off with compressed air. ★ Replace the main harness if the terminals [A] of the main harness connectors are cracked, bent, or otherwise...

Fuel pressure inspection

Notes: This inspection can determine which trouble the DFI system has, mechanical or electrical trouble. It is preferable to measure the fuel pressure while running the motorcycle when the trouble has occurred in order to know symptom well. Be sure...

Notes: This inspection can determine which trouble the DFI system has, mechanical or electrical trouble. It is preferable to measure the fuel pressure while running the motorcycle when the trouble has occurred in order to know symptom well. Be sure...

Fuel flow rate inspection

Note. Be sure the battery is fully charged. Warning! Gasoline is extremely flammable and can be explosive under certain conditions. Make sure the area is well-ventilated and free from any source of flame or sparks; this includes any appliance with a...

Note. Be sure the battery is fully charged. Warning! Gasoline is extremely flammable and can be explosive under certain conditions. Make sure the area is well-ventilated and free from any source of flame or sparks; this includes any appliance with a...

Fuel pump — removal and installation

Fuel pump removal Caution! Never drop the fuel pump, especially on a hard surface. Such a shock to the pump can damage it. Warning! Gasoline is extremely flammable and can be explosive under certain conditions. Make sure the area is well-ventilated...

Fuel pump removal Caution! Never drop the fuel pump, especially on a hard surface. Such a shock to the pump can damage it. Warning! Gasoline is extremely flammable and can be explosive under certain conditions. Make sure the area is well-ventilated...

Pump screen, fuel filter cleaning

The pump screen [A] and fuel filter [B] are built into the pump and cannot be cleaned or checked. ★ If the pump screen or fuel filter is suspected of clogging or being damaged, replace it with the fuel pump as a set.

The pump screen [A] and fuel filter [B] are built into the pump and cannot be cleaned or checked. ★ If the pump screen or fuel filter is suspected of clogging or being damaged, replace it with the fuel pump as a set.

Fuel pump — operation inspection

Operation inspection Note. Be sure the battery is fully charged. Just listen to the pump sound in the fuel tank to confirm pump operation. Turn the ignition switch ON and make sure that the fuel pump operates (make light sounds) for 3 seconds, and...

Operation inspection Note. Be sure the battery is fully charged. Just listen to the pump sound in the fuel tank to confirm pump operation. Turn the ignition switch ON and make sure that the fuel pump operates (make light sounds) for 3 seconds, and...

Fuel injectors — removal and installation

Caution! Never drop the injector, especially on a hard surface. Such a shock to the injector can damage it. Injector removal Warning! Gasoline is extremely flammable and can be explosive under certain conditions. Turn the ignition switch OFF....

Caution! Never drop the injector, especially on a hard surface. Such a shock to the injector can damage it. Injector removal Warning! Gasoline is extremely flammable and can be explosive under certain conditions. Turn the ignition switch OFF....

Injector fuel line inspection

Remove: Fuel Tank (see Fuel tank removal ) Fuel Hose (see Fuel hose replacement in the Periodic Maintenance chapter) Check the injector fuel line for leakage as follows: Connect a commercially available vacuum/pressure pump [A] to the nipple of the...

Remove: Fuel Tank (see Fuel tank removal ) Fuel Hose (see Fuel hose replacement in the Periodic Maintenance chapter) Check the injector fuel line for leakage as follows: Connect a commercially available vacuum/pressure pump [A] to the nipple of the...

Fuel injectors — audible inspection

Audible inspection Start the engine. Insert a screwdriver from the engine right side between the fuel tank bottom end and the engine top end. Apply the tip of a screwdriver [A] to the injector [B]. Put the grip end onto your ear, and listen whether...

Audible inspection Start the engine. Insert a screwdriver from the engine right side between the fuel tank bottom end and the engine top end. Apply the tip of a screwdriver [A] to the injector [B]. Put the grip end onto your ear, and listen whether...

Fuel injector power source voltage inspection

Remove the ECU (see ECU removal ). Do not disconnect the ECU connector. Connect a digital meter to the ECU connector, using the needle adapter. Special Tool - Needle Adapter Set: 57001-1457 Measure the power source voltage with the engine stopped,...

Remove the ECU (see ECU removal ). Do not disconnect the ECU connector. Connect a digital meter to the ECU connector, using the needle adapter. Special Tool - Needle Adapter Set: 57001-1457 Measure the power source voltage with the engine stopped,...

Injector signal test

Prepare two test light sets with male terminals as shown. Rating of Bulb [A]: 12 V x 3-3.4 W Terminal Width [B]: 1.8 mm Terminal Thickness [C]: 0.8 mm Caution! Do not use larger terminals than specified above. A larger terminal could damage the...

Prepare two test light sets with male terminals as shown. Rating of Bulb [A]: 12 V x 3-3.4 W Terminal Width [B]: 1.8 mm Terminal Thickness [C]: 0.8 mm Caution! Do not use larger terminals than specified above. A larger terminal could damage the...

Injector resistance inspection

Remove: Fuel Tank (see Fuel tank removal ). Disconnect the connector from the injector (see Injector removal ). Measure the injector resistance with a digital voltmeter [A]. Injector resistance: Connections to injector: Meter (+) Meter (-) #1: W/R...

Remove: Fuel Tank (see Fuel tank removal ). Disconnect the connector from the injector (see Injector removal ). Measure the injector resistance with a digital voltmeter [A]. Injector resistance: Connections to injector: Meter (+) Meter (-) #1: W/R...

Injector unit test

Use two wires [A] and the same test light set [B] as in " Injector Signal Test ". Rating of Bulb [C]: 12 V x (3-3.4) W 12 V Battery [D] Caution! Be sure to connect the bulb in series. The bulb works as a current limiter to protect the solenoid in...

Use two wires [A] and the same test light set [B] as in " Injector Signal Test ". Rating of Bulb [C]: 12 V x (3-3.4) W 12 V Battery [D] Caution! Be sure to connect the bulb in series. The bulb works as a current limiter to protect the solenoid in...

Throttle grip and cables

Throttle grip free play inspection Refer to Throttle Control System Inspection in the Periodic Maintenance Chapter. Throttle grip free play adjustment Loosen the locknuts [A] and screw the adjusters [B] all the way in so as to give the throttle grip...

Throttle grip free play inspection Refer to Throttle Control System Inspection in the Periodic Maintenance Chapter. Throttle grip free play adjustment Loosen the locknuts [A] and screw the adjusters [B] all the way in so as to give the throttle grip...

Throttle body assy

Idle speed inspection Refer to Idle Speed Inspection in the Periodic Maintenance Chapter. Idle speed adjustment Refer to Idle Speed Adjustment in the Periodic Maintenance Chapter. Throttle bore cleaning Check the throttle bore for cleanliness as...

Idle speed inspection Refer to Idle Speed Inspection in the Periodic Maintenance Chapter. Idle speed adjustment Refer to Idle Speed Adjustment in the Periodic Maintenance Chapter. Throttle bore cleaning Check the throttle bore for cleanliness as...

Air cleaner — removal and installation

Air cleaner element removal/installation Refer to the Air cleaner element replacement in the Periodic Maintenance chapter. Air cleaner housing removal Remove the air cleaner housing bolts [A]. Clear the idle speed screw [A] from the recess on the...

Air cleaner element removal/installation Refer to the Air cleaner element replacement in the Periodic Maintenance chapter. Air cleaner housing removal Remove the air cleaner housing bolts [A]. Clear the idle speed screw [A] from the recess on the...

Fuel tank removal

Warning! Gasoline is extremely flammable and can be explosive under certain conditions. Make sure the area is well-ventilated and free from any source of flame or sparks; this includes any appliance with a pilot light. Do not smoke. Turn the...

Warning! Gasoline is extremely flammable and can be explosive under certain conditions. Make sure the area is well-ventilated and free from any source of flame or sparks; this includes any appliance with a pilot light. Do not smoke. Turn the...

Fuel tank installation

Read the above WARNING . Route the hoses correctly (see Cable, wire and hose routing section in the Appendix chapter). For California model, note the following: To prevent the gasoline from flowing into or out of the canister, hold the separator...

Read the above WARNING . Route the hoses correctly (see Cable, wire and hose routing section in the Appendix chapter). For California model, note the following: To prevent the gasoline from flowing into or out of the canister, hold the separator...

Fuel tank and cap inspection

Visually inspect the gasket [A] on the tank cap for any damage. ★ Replace the gasket if it is damaged. Check to see if the breather pipe [B] in the tank is not clogged. ★ If the breather pipe is clogged, blow the breather free with compressed air....

Visually inspect the gasket [A] on the tank cap for any damage. ★ Replace the gasket if it is damaged. Check to see if the breather pipe [B] in the tank is not clogged. ★ If the breather pipe is clogged, blow the breather free with compressed air....

Fuel tank cleaning

Warning! Clean the tank in a well-ventilated area, and take care that there are no sparks or flame anywhere near the working area. Because of the danger of highly flammable liquids, do not use gasoline or low-flash point solvent to clean the tank....

Warning! Clean the tank in a well-ventilated area, and take care that there are no sparks or flame anywhere near the working area. Because of the danger of highly flammable liquids, do not use gasoline or low-flash point solvent to clean the tank....

Breather check valve inspection

Remove: Cap [A] and Bolt Ignition Switch [B] Bolt [C] Clamp [D] Breather Hoses Breather Check Valve [E] Check to see if the valve [A] slides smoothly when pushing it in with a wooden or other soft rod, and see if it comes back to its seat by...

Remove: Cap [A] and Bolt Ignition Switch [B] Bolt [C] Clamp [D] Breather Hoses Breather Check Valve [E] Check to see if the valve [A] slides smoothly when pushing it in with a wooden or other soft rod, and see if it comes back to its seat by...

Evaporative emission control system

The Evaporative Emission Control System for California Model routes fuel vapors from the fuel system into the running engine or stores the vapors in a canister when the engine is stopped. Although no adjustments are required, a thorough visual...

The Evaporative Emission Control System for California Model routes fuel vapors from the fuel system into the running engine or stores the vapors in a canister when the engine is stopped. Although no adjustments are required, a thorough visual...

Similar subsections of other motorcycle models

Fuel and exhaust systems motorcycle БМВ F 650 GS (2000-2007)

Fuel and exhaust system motorcycle Ducati ST2 (1997-2003)

Fuel and control system motorcycle Honda VTX 1800 C (2001-2008)

Fuel system motorcycle Suzuki DRZ 250 (1996-2007)

Fuel and control system motorcycle Triumph Street Triple 765 (2017-2024, 4 generation)

- Information for owner

- Introduction to manual

- Maintenance

- Engine and systems

- Engine repair

- Fuel system (DFI)

- Cooling system

- Lubrication system

- Transmission

- Running gear and frame

- Frame and hinged elements

- Front suspension and handlebar

- Rear suspension

- Brake system

- Wheels and tires

- Electric equipment

- Equipment and devices

- Lighting and lamps

- Starting and charging system

- Ignition system

- Electrical circuits