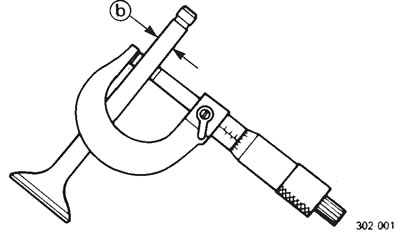

1. Measure: valve-stem-to-valve-guide clearance

Valve-stem-to-valve-guide clearance = Valve guide inside diameter (a) - Valve stem diameter (b)

Out of specification Replace the valve guide.

Valve-stem-to-valve-guide clearance:

- Intake 0.010-0.037 mm

- Limit: 0.08 mm

- Exhaust 0.025-0.052 mm

- Limit: 0.10 mm

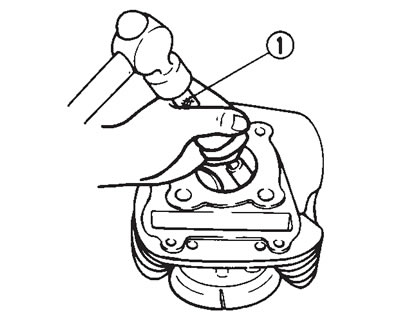

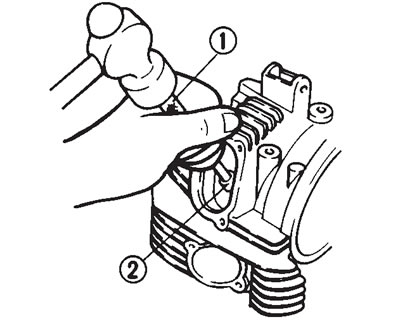

2. Replace: valve guide

Note: To ease valve guide removal and installation, and to maintain the correct fit, heat the cylinder head to 100°C (212°K) in an oven.

a. Remove the valve guide with a valve guide remover (1).

b. Install the new valve guide with a valve guide installer (2) and valve guide remover (1).

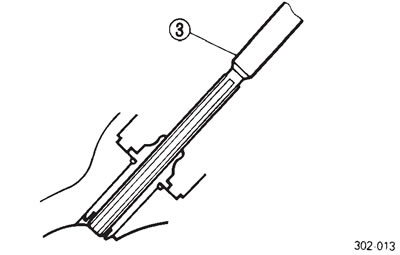

c. After installing the valve guide, bore the valve guide with a valve guide reamer (3) to obtain the proper valve-stem-to-valve-guide clearance.

Note: After replacing the valve guide, reface the valve seat.

Valve guide remover and installer (8 mm): 90890-04014

3. Eliminate: carbon deposits (from the valve face and valve seat)

4. Check:

- valve face. Pitting/wear → Grind the valve face.

- valve stem end. Mushroom shape or diameter larger than the body of the valve stem → Replace the valve.

5. Measure: valve margin thickness (a)

Out of specification → Replace the valve.

- Valve margin thickness limit: 0.8 mm

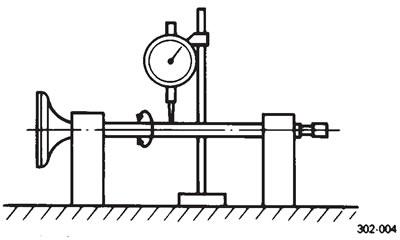

6. Measure: valve stem runout

Out of specification → Replace the valve.

Note:

- When installing a new valve, always replace the valve guide.

- If the valve is removed or replaced, always replace the valve stem seal.

- Valve stem runout: 0.03 mm