Note: Aligning the middle gear is necessary when any of the following parts are replaced:

- Crankcase

- Middle drive shaft

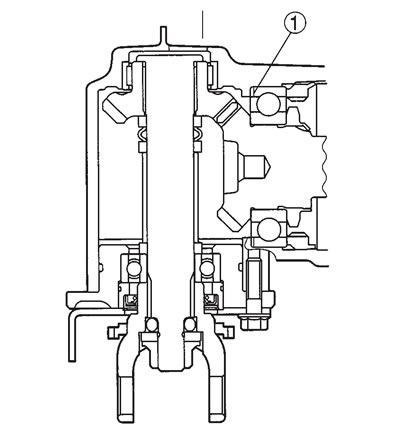

1. Select: middle drive gear shim(-s) (1)

Note: Select the middle drive gear shim(-s) (1) by calculating the middle drive gear shim thickness and then measuring the middle gear backlash.

a. Position the middle drive gear with the appropriate shim(-s) (1) that has had its respective thickness calculated from information marked on the crankcase and the end of the middle drive gear.

b. To find middle drive gear shim thickness "A", use the following formula.

Middle drive gear shim thickness: "A" = (a) - (c)

(a) = "43.00"

(b) = a numeral on the upper crankcase near the main bearing selection numbers and which is added to the nominal size "42"

Example: (a) is 43.00

If the upper crankcase is marked "46" (b)

(c) is 42.46 (i.e., 42.00 + 0.46 = 42.46)

"A" = 43.00 - 42.46 = 0.54

Round off to the hundredths digit and select the appropriate shim(-s).

Note: In the above example, the calculated number is 0.54. The chart instructs you to round off the 4 to 5. Thus, the shim thickness is 0.55 mm.

| Hundredths | Rounded value |

| 0, 1, 2 | 0 |

| 3, 4, 5, 6, | 5 |

| 7, 8, 9 | 10 |

Shims are supplied in the following thickness.

- Middle drive pinion gear shim: Thickness (mm): 0.10, 0.15, 0.20