Removing gearbox shafts

Pull sliding gears (13, 16) with bearing (15) and washer (14) off the mainshaft.

Strike mainshaft (1) and countershaft (17) lightly with a plastic-faced hammer and remove them.

Disassembling and reassembling mainshaft

Clamp the mainshaft in a vise fitted with protective jaws.

Caution! Do not alter the stop on the special pliers, BMW No. 23 4 500, in order to avoid opening up the circlip too much.

Using special pliers, BMW No. 23 4 500, push back retaining ring (7) slightly so that retaining ring (12), which is retained by angled ring (11), can be removed.

Pull off gearwheel (10) with needle roller bearing (9) and washer (8).

Remove retaining ring (7).

Remove gearwheel (6).

Remove circlip (5) with washer (4).

Pull off gearwheel (3).

Pull off needle bearing (2).

Note:

- Check all bearings, bearing journals, tooth edges, keyways and annular grooves for wear.

- Always replace gearwheels complete with their matching gearwheels as pairs.

- Edges of ring grooves must not be blunt.

- Always renew circlips and install them only with special pliers, BMW No. 234500.

Installation is the reverse of the removal procedure: pay particular attention to the following.

Position retaining ring (7) approx. 3 mm (0.12 in) below the groove. After installing retaining ring (12), push retaining ring (7) up with gearwheel (6) until the retaining ring is seated in its groove.

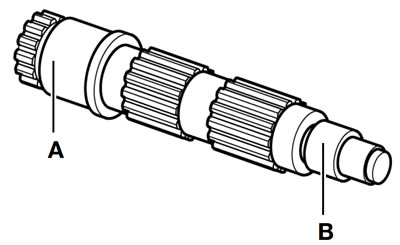

Checking mainshaft for wear

Wear limits:

- "A" Shaft diameter, magneto side: 24.98 mm (0.983 in)

- "B" Shaft diameter, clutch side: 16.98 mm (0.669 in)

- Runout: 0.02 mm (0.0008 in)

Disassembling and reassembling compensating shaft

Clamp the compensating shaft in a vise fitted with protective jaws.

Pull off gearwheels (1, 2).

Pull off needle roller bearing (3) and washer (4).

Pull off gearwheel (5).

Remove circlip (6) with special pliers, BMWNo. 23 4 500.

Pull off washer (7) and gearwheel (8).

Note: Inspect all bearings, bearing journals, tooth flanks, keyways and ring grooves for signs of wear.

Renew gears only together with the corresponding meshing gears.

Edges of ring grooves must not be blunt.

Always renew circlips and install them only with special pliers, BMW No. 23 4 500.

Assembly is the reverse of the disassembly procedure.

Checking countershaft for wear

Wear limits:

- "A" Shaft diameter, magneto side: min. 16.98 mm (0.669 in)

- "B" Shaft diameter, clutch side: min. 24.97 mm (0.983 in)

- Inside diameter of bearing seat 4th gear sliding gearwheel: max. 25.53 mm (1.005 in)

- Runout: 0.02 mm (0.0008 in)

Replacing gearbox mainshaft bearings

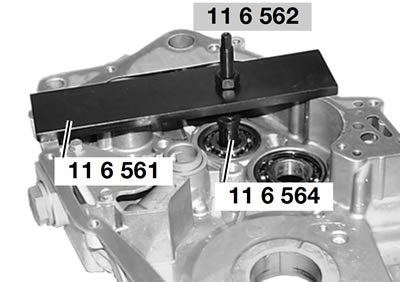

Note:

- To protect the gasket surfaces of the engine block, place the old gasket under the bearing puller.

- Always renew the mainshaft sealing ring.

Heat the left of the engine block to 80-100°C (176-212°F).

Using bearing puller plate, BMW No. 11 6 561, spindle, BMW No. 11 6 562,and spreader sleeve, BMW No. 11 6 564, pull off the ball bearing.

Drive out the mainshaft sealing ring from the inside.

Heat the right of the engine block to 80-100°C (176-212°F).

Working from outside and using a suitable socket, press the bearing through to the other side.

Installation is the reverse of the removal procedure: pay particular attention to the following.

To install the bearings, heat the engine block to 80-100°C (176-212°F).

Replacing gearbox compensating shaft bearings

Note: To protect the gasket surfaces of the engine block, place the old gasket under the bearing puller.

Heat the left of the engine block to 80-100°C (176-212°F).

Using bearing puller plate, BMW No. 11 6 561, spindle, BMW No. 11 6 562, and spreader sleeve, BMW No. 11 6 565, pull off the ball bearing.

Heat the right of the engine block to 80-100°C (176-212°F).

Using bearing puller plate, BMW No. 11 6 561, spindle, BMW No. 11 6 562, and spreader sleeve, BMW No. 11 6 564, pull off the ball bearing.

Installation is the reverse of the removal procedure: pay particular attention to the following.

To install the bearings, heat the engine block to 80-100°C (176-212°F).

Wear limit values for bearing seats in housing:

- Magneto side:

- Countershaft: max. 0 46.99 mm (1.850 in)

- Mainshaft: max. 0 62.02 mm (2.442 in)

- Clutch side:

- Countershaft: max. 0 51.99 mm (2.047 in)

- Mainshaft: max. 0 46.99 mm (1.850 in)

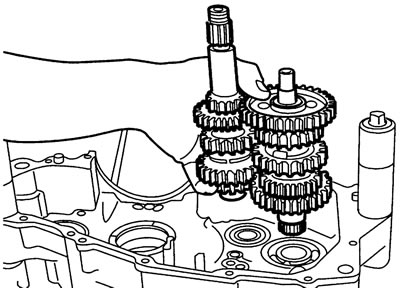

Installing gearbox shafts

Note: The gearbox shafts are easier to install if the crankshaft is removed beforehand.

Install the countershaft and mainshaft together, coating the main bearing points with Optimoly MP 3.

Drive the shafts in against their seats with light blows of a plastic-faced hammer.

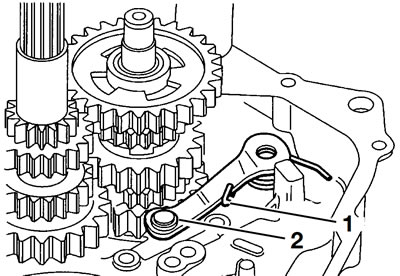

Installing selector shaft

Install index lever (2) with index spring (1) in housing.

Engage pawl spring (4) on shift pawl (3).

Insert selector shaft (6) in housing and secure index lever (5) in position.

Push hairpin spring (7) with sleeve (8) on to selector shaft (7).

Engage the hairpin spring to the bearing journal.

Installing selector forks

Insert selector fork (9) in shift gear of countershaft.

Insert selector rod and swivel together with the selector fork in the direction of the crankshaft.

Insert selector forks (10, 11) in the corresponding shift gears of the mainshaft.

Insert selector rod and swivel it outwards together with the selector forks.

Drive the selector shafts onto their seats with light blows of a plastic-faced hammer.

Installing selector drum

Install the selector drum in the neutral position. The contact pin in the plastic plate is above the neutral indicator switch in the housing.

Press back index lever and selector pawl and install selector drum.

Move index lever and selector pawl into mesh.

Turn selector forks so that they engage the selector drum.

Note: Select all gears in succession, at the same time checking that the selector pawl is withdrawn freely from the selector drum in all gears.

Check gearbox functions.

Assemble the engine.

Note: The clicking sound as the selector pawl engages must be clearly audible.

Select all gears once again and move the shift lever slowly to the "0" position.

Cover the splines on the selector shaft with slide-on sleeve, BMW No. 21 4 620.

Using drift, BMW No. 21 4 630, drive in sealing ring.

Drive in the mainshaft sealing ring with drift, BMW No. 23 4 550, and sliding sleeve, BMW No. 23 4 540.

Install the engine. See Group 11.