General

The heat exchangers, or radiators, for both engine cooling and oil cooling are bolted together in a single radiator/oil cooler assembly. The radiator/oil cooler assembly is fasten to the frame with:

- Double threaded studs near the steering head.

- Two pins and rubber grommets on the bottom of the oil cooler that fit the frame cross member.

Removal

Warning! Do not remove the filler cap when the engine is hot. The cooling system is under pressure and hot coolant and steam may escape causing severe burns. Allow engine to cool before servicing the cooling system.

1. Allow cooling system to cool.

2. See Figure 6-19. Remove right side cover (1) and maxifuse.

Figure 6-19. Radiator covers: 1. Side cover; 2. Fastener; 3. Rubber grommet; 4. Radiator/oil cooler assembly; 5. Fastener; 6. Radiator cover; 7. Chrome inlet bezel; 8. Fastener; 9. Fastener and washer; 10. Radiator side cover; 11. Side cover fastener

Warning! To protect against shock and accident start-up of vehicle, disconnect the negative battery cable before proceeding. Inadequate safety precautions could result in death or serious injury.

3. Remove negative battery cable.

4. Remove airbox decorative cover, airbox cover, air filter cover and air filter. See 1.4 Airbox and air filter.

5. See Figure 6-19. Remove fasteners (11) and left and right radiator side covers (10).

6. Cover front fender with shop towel or protective cover. Remove fasteners and washers (9) on each side of radiator cover (6). Remove radiator cover with chrome inlet bezels (7) attached.

7. Open seat and remove pressure cap.

8. See Figure 6-20. Place a suitable container under radiator. Remove radiator drain plug (11) and drain coolant from radiator. Replace drain plug. See 6.3 Engine coolant.

9. Place a container under engine, remove oil filler plug/dip-stick, and oil drain plug and drain oil. Replace dipstick and drain plug. See 1.6 Engine oil and filter.

Note. Both the oil line sleeves remain threaded onto the oil cooler and the lines remain clipped to the radiator/oil cooler assembly. The drain hose from the expansion bottle also remains clipped to the assembly.

10. Disconnect:

- a. Crank position sensor connector [79].

- b. Top and bottom fan power connectors [97T], [97В].

- c. Stator to voltage regulator connector [46].

11. See Figure 6-16. Use a long thin screwdriver (Snap-on Part No. SDD1410) to loosen worm drive clamps on both engine coolant hoses at radiator.

12. See Figure 6-20. Disconnect the end of drain hose (4) from the overflow bottle.

Figure 6-20. Radiator/oil cooler assembly: 1. Double threaded stud; 2. Socket connector; 3. Plastic ties; 4. Drain hose; 5. Spacer; 6. Bushing; 7. Nut; 8. Grommet; 9. Washer; 10. Nut @ 19-27 Nm (15-20 ft-lbs); 11. Engine coolant drain plug; 12. Oil cooler pipe bracket; 13. Bolt @ 15 Nm (11 ft-lbs); 14. Fan retainer; 15. Fastener @ 9-11 Nm (80-97 in-lbs); 16. Oil cooler outlet pipe; 17. Oil cooler; 18. Oil pipe sleeve @ 50-55 Nm (37-40 ft-lbs); 19. Oil cooler inlet pipe; 20. Engine coolant radiator; 21. Cooling fan; 22. Grommet; 23. Clamp; 24. Acorn nut; 25. Nut; 26. Cross member

13. See Figure 6-20. Loosen but do not remove nuts (10) holding assembly to front engine mount studs (1). Remove fasteners under radiator assembly that hold cross member to frame. Gently pull bottom of radiator/oil cooler assembly forward.

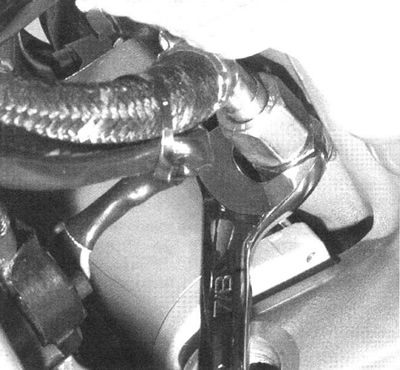

14. See Figure 6-21. Holding each oil line fitting with a wrench and holding a cup under ends of oil lines, loosen and unthread sleeves at crankcase (oil in) and oil filter (oil out).

Figure 6-21. Holding oil line fitting with angled wrench

15. Remove nuts (10) holding radiator assembly to engine mount studs (1) and remove radiator/oil cooler assembly.

Installation

Caution! Be sure to carefully clean the front surface of the radiator regularly. Leaves and other debris can collect on the radiator surface and degrade radiator performance. This could lead to engine overheating and engine damage.

1. Cover front fender with a shop towel or protective cover.

2. See Figure 6-20. Hold radiator/oil cooler assembly up to frame and thread on oil line sleeves (18).

3. Thread on but do not tighten nuts (J0) holding radiator/oil cooler assembly to engine mount studs (1).

Note. The oil lines should be angled and routed so there is no interference between the radiator fans and the oil lines when the radiator is in place on the frame.

4. See Figure 6-21. While holding each oil line fitting (oil in & oil out) with an angled wrench, install and tighten oil line sleeves to 53-58 Nm (39-42 ft-lbs).

5. See Figure 6-20. Slip cross member (26) over grommets (22) on radiator mounting pins. Install cross member to frame.

6. Tighten cooling system fasteners to following:

- a. Cross member fasteners to 20-26 Nm (15-19 ft-lbs).

- b. Top mounting nuts (10) to 19-27 Nm (15-20 ft-lbs).

- c. Pipe clamp to 6.5 Nm (57 in-lbs).

- d. P-clamp to 6-10 Nm (53-88 in-lbs).

- e. Hose clamps to 3-4 Nm (27-35 in-lbs).

7. Route drain hose (4) to overflow bottle.

8. Install radiator cover.

9. Connect:

- a. Crank position sensor connector [79].

- b. Top and bottom fan power connectors [97T], [97В].

- c. Stator to voltage regulator connector [46].

10. Install left and right side radiator covers.

11. Fill engine with oil. See 1.6 Engine oil and filter.

12. Install air filter bottom, velocity stacks, о-rings and breather hose. See 1.4 Airbox and air filter.

13. Loosen air bleed plug. Fill with GENUINE HARLEY-DAVIDSON EXTENDED LIFE ANTIFREEZE & COOLANT through filler neck. See 6.3 Engine coolant.

14. Tighten air bleed plug to 9-11 Nm (80-97 in-lbs). and replace pressure cap.

15. Install air filter, air filter top and air filter cover. See 1.4 Airbox and air filter.

Caution! Attach the cables to the correct battery terminals using the proper torque. Overtightening bolts can damage battery terminals and incorrect connections may damage the motorcycle’s electrical system.

Warning! Always connect the positive battery cable first. If the positive cable should contact ground with the negative cable installed, the resulting sparks may cause a battery explosion that could result in death or serious injury.

16. Replace the negative battery cable. Tighten to 6.8-10.8 Nm (60-96 in-lbs).

17. Install right side cover and maxi-fuse.

18. After running engine, inspect oil sleeves and fittings for oil leaks. Check oil level and add oil if required.

19. After running engine, check coolant level in overflow bottle with coolant cold with motorcycle on jiffy stand. If level is below COLD FULL line, remove cap from overflow bottle and add antifreeze until fluid level reaches COLD FULL line.

20. Continue to run engine, check level, and add antifreeze until fluid level remains at COLD FULL line with motorcycle on jiffy stand.