Description

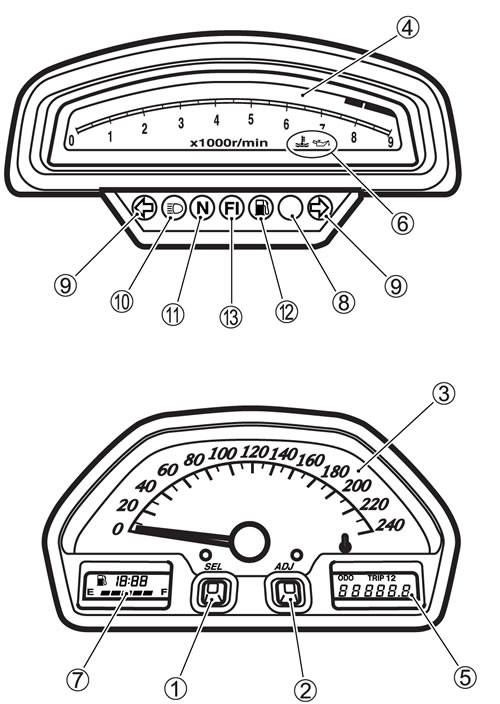

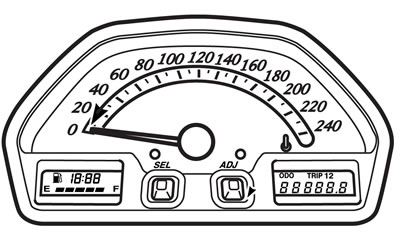

- This speedometer and tachometer mainly consists of the stepping motor (except for tachometer), LCD (Liquid Crystal Display) and LED (Light Emitting Diode).

- The speedometer pointer is driven by the stepping motor.

- The LCDs indicate Tachometer, Engine coolant and Oil pressure temp mark, Odo/Trip1/Trip2/FI and Clock, Fuel level respectively.

LED (Light Emitting Diode)

- LED is used for the illumination light and each indicator light.

- LED is maintenance free. LED is less electric-power consuming and stronger to vibration resistance compared to the bulb.

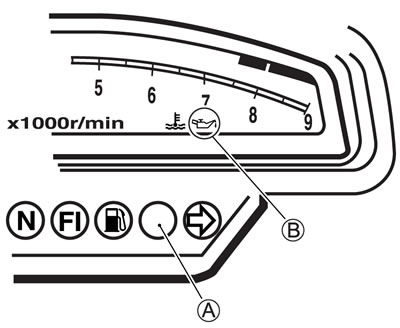

Tachometer indicator lamp

The tachometer light up for 1.0 second and then it operates 9 000 → 0 r/min one time.

1. Select switch (Odo/Trip1/Trip2/FI); 2. Adjust switch (Trip/Clock); 3. Speedometer; 4. Tachometer; 5. LCD (Odo/Trip1/Trip2/FI); 6. LCD (Oil pressure/Engine coolant temperature indicator mark); 7. LCD (Clock/FueI level); 8. LED (Oil pressure/Engine coolant temperature indicator light); 9. LED (Turn signal indicator light); 10. LED (High-beam indicator light); 11. LED (Neutral indicator light); 12. LED (Fuel level indicator light); 13. LED (FI indicator light)

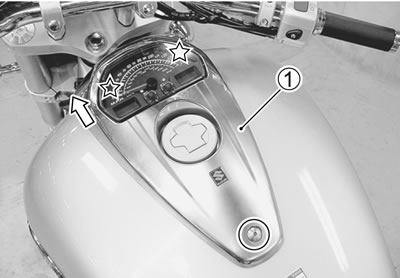

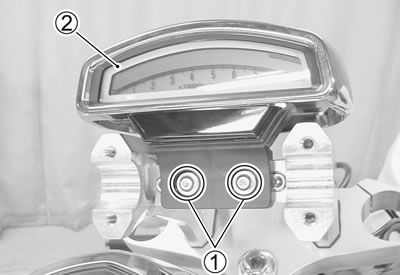

Speedometer removal and disassembly

- Disconnect the speedometer lead wire coupler. (6-3)

- Remove the screw.

- Remove the speedometer 1.

Note: Indicates hook location.

Caution: When disconnecting and reconnecting the speedometer coupler, make sure to turn OFF the ignition switch, or electronic parts may get damaged.

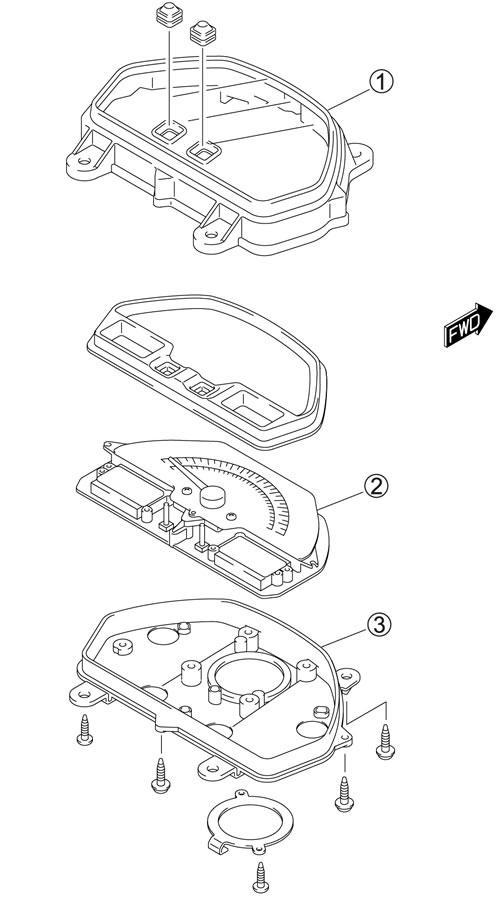

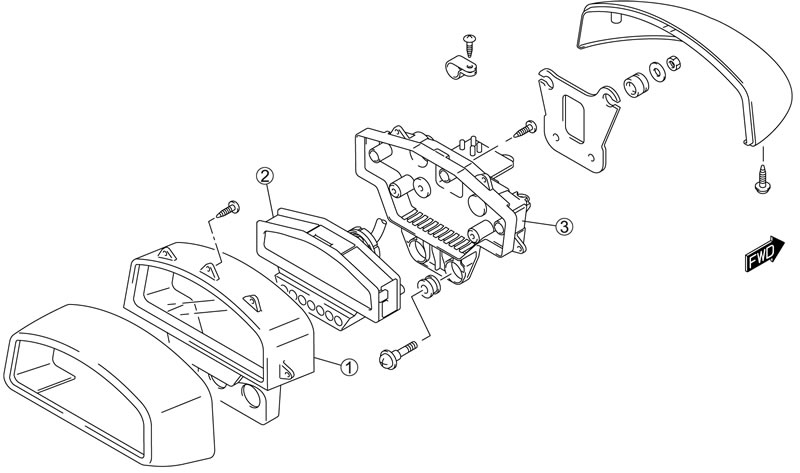

- Disassemble the speedometer as follows.

Caution: Do not attempt to disassemble the speedometer unit 2.

1. Speedometer cover; 2. Speedometer unit; 3. Speedometer case

Tachometer removal and disassembly

- Remove the handlebar. (9-30)

- Remove the head light. (9-15)

- Remove the screws 1.

- Disconnect the tachometer lead wire coupler and remove the tachometer 2.

- Disassemble the tachometer as follows.

Caution: Do not attempt to disassemble the tachometer unit 2.

1. Tachometer cover; 2. Tachometer unit; 3. Tachometer case

Inspection LED (light emitting diode)

Check that the LED lights (FI indicator light, Fuel level indicator light) immediately after turning the ignition switch on. Also, other LED lights (Neutral indicator light, High-beam indicator light and Turn signal indicator light) can be checked by depending on each switch position.

If the LED fails in operation, replace the combination meter unit with a new one after checking its wire harness/coupler.

Stepping motor

Check that the pointer calibrates itself immediately after turning the ignition switch on and stops at zero point.

If abnormal condition is found, replace the combination meter unit with a new one after checking its wire har-ness/coupler.

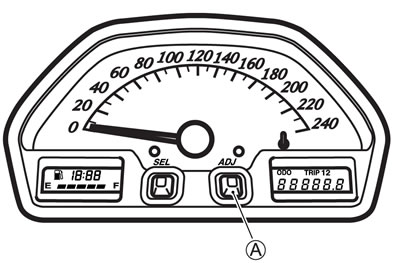

Note: The pointer may not return to the proper position even turning the ignition switch on under low temperature condition. In that case, you can reset the pointer to the proper position by following the instruction below:

- 1) With the function switch А pressed, turn the ignition switch on.

- 2) Release the function switch А, 3 to 5 seconds after turning the ignition switch on.

- 3) Press the function switch А twice (within 1 second). → Reset

Complete the operation within 10 seconds after the ignition switch has been turned on.

| Time | Ignition switch | Adjuster switch А |

| OFF | PUSH | |

| 0 | ON ↓ | |

| • • | ||

| 3 sec. • 5 sec. | Release | |

| • • • • | Push ↓ Push→Reset | |

| 10 sec. |

Pointer will return to the starting point right after the completion of the operation. In the case of the pointer not returning to the proper position after doing above, replace the combination meter unit.

Engine coolant temperature meter and indicator

ECT sensor inspection (8-9).

- Remove the right frame side cover. (9-5)

- Remove the right air cleaner box. (6-13)

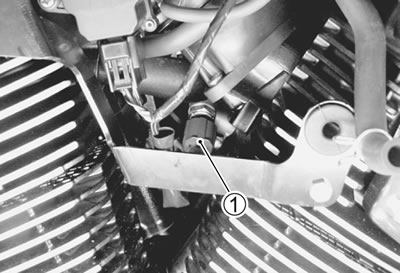

- Disconnect the ECT sensor coupler 1.

Caution: When connecting and disconnecting the engine coolant temperature sensor lead wire coupler, make sure to turn OFF the ignition switch, or electronic parts may get damaged.

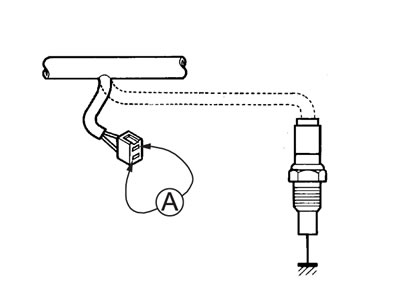

- Connect the variable resistor А between the terminals.

- Disconnect the oil pressure switch lead wire from the oil pressure switch.

Note: Leave the oil pressure switch lead wire open.

- Turn the ignition switch ON.

- Check the LCD and LED operations when the resistance is adjusted to the specified values.

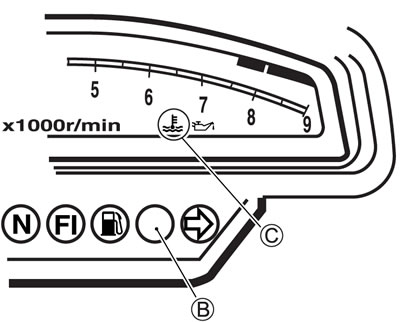

| Resistance А | LED В | LCD С | Water temperature |

| 0.1 kΩ and over | OFF | — | 120°C below |

| 0.1 kΩ and below | ON | ON | 120°C and over |

If either one or all indications are abnormal, replace the combination meter with a new one.

Note: If the engine stop switch is turned OFF or side-stand/ignition inter-lock system is not working while the ignition switch is ON, the LCD displays "CHEC". But it is not a malfunction. This condition implies that combination meter receives no signal from the ECM. In that case, they are restored to normal indication by turning the engine stop switch to RUN position.

Fuel level indicator switch inspection

- Remove and disassemble the fuel pump assembly. (6-8)

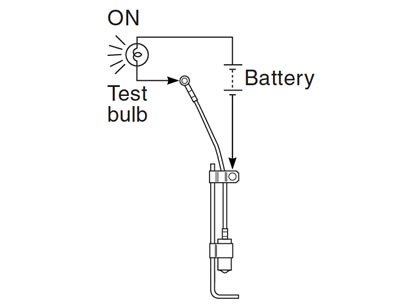

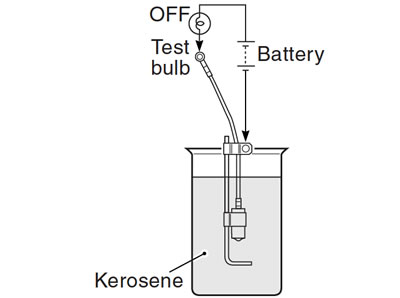

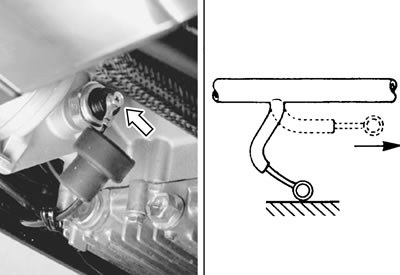

- Connect 12 V battery and test bulb (12 V, 3.4 W) to the fuel level indicator switch as shown in the right illustration. The bulb should come on after one minutes if the switch is in good condition.

- When the switch is immersed in kerosene under the above condition, the bulb should go out. If the bulb remains lit, replace the unit with a new one.

Caution:

- When the bulb turns off, immediately pick up the switch from kerosene.

- After the check has been completed, wash the switch with gasoline.

Fuel level indicator light inspection

If the fuel level indicator light does not function properly, check the fuel level indicator switch and its lead wire/coupler.

If the fuel level indicator switch and its lead wire/coupler are functioning properly, replace the tachometer with a new one.

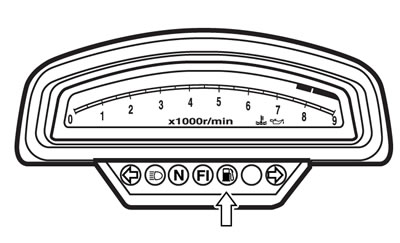

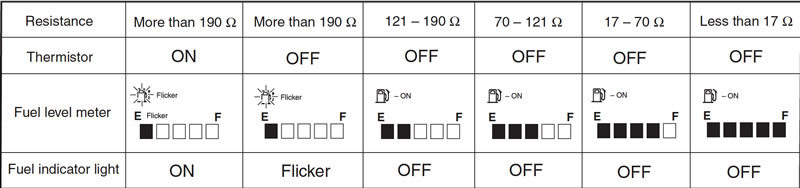

Fuel level meter inspection

- Lift and support the fuel tank. (6-3)

- Disconnect the fuel pump lead wire coupler 1.

- Connect variable resistor between the Light green and Black lead wires at the wire harness.

- Turn the ignition switch "ON" position and wait for approx. 40 seconds.

Check the display of fuel meter as shown below, If any abnormality is found, replace the combination meter with a new one.

Note: Side-stand is "ON" (side-stand up) position when inspecting it.

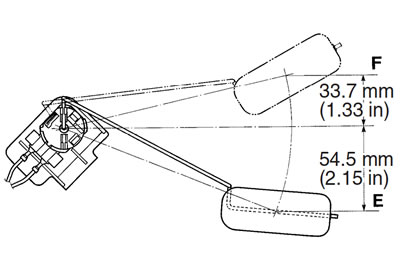

Fuel level gauge inspection

- Remove the fuel level gauge assembly. (6-8)

- Measure the resistance at each fuel level gauge float position. If the resistance is incorrect, replace the fuel level gauge with a new one.

| Float position | Resistance |

| 33.7 mm (1.33 in) | Approx. 10 Ω |

| 54.5 mm (6.67 in) | Approx. 216 Ω |

- 09900-25008: Multi-circuit tester set

- Tester knob indication: Resistance (Ω)

Speedometer

If the speedometer, odometer or trip meter does not function properly, inspect the speedometer sensor and connection of couplers. If the speed sensor and connection are functioning properly, replace the meter with a new one.

Speedometer sensor

- Remove the left frame side cover. (9-5)

- Remove the secondary gear case cover. (3-6)

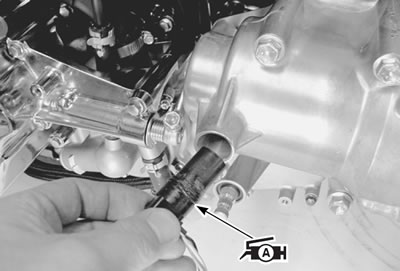

- Disconnect speedometer sensor coupler 1.

- Remove the speedometer sensor 2 by removing its mounting bolt.

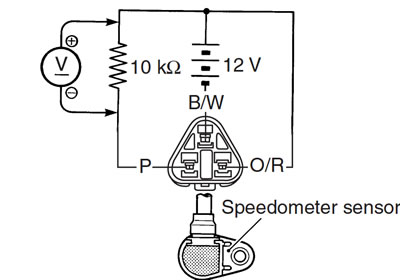

- Connect 12 V battery, 10 kΩ resistor and the multi-circuit tester as shown in the right illustration.

- O/R : Orange with Red tracer

- B/W : Black with White tracer

- P: Pink

- 09900-25008: Multi-circuit tester set

- Tester knob indication: Voltage

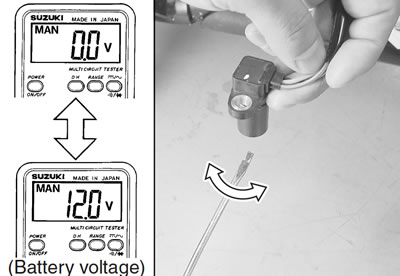

- Under above condition, if a suitable screwdriver touching the pick-up surface of the speedometer sensor is moved, the tester reading voltage changes (0 V12 V or 12 V0 V). If the tester reading voltage does not change, replace the speedometer sensor with a new one.

Note: The highest voltage reading in this test will be the same as that of battery (12 V).

- Apply SUZUKI SUPER GREASE "A" to the speedometer sensor O-ring before installing it.

- 99000-25010: SUZUKI SUPER GREASE "A" or equivalent

Oil pressure indicator

Note: Before inspecting the oil pressure switch, check if the engine oil level is correct. (2-17)

- Disconnect the oil pressure switch lead wire from the oil pressure switch.

- Turn the ignition switch ON.

- Check if the oil pressure indicator А and LCD В will light, when grounding the lead wire.

If any indications are abnormal, replace the combination meter with a new one after checking connection of couplers.

Note: Install the rubber cover correctly after inspecting it.