The decision to overhaul the cylinder is often based on the results of a compression test. Periodic maintenance records kept at your dealership should include compression readings for each maintenance service.

Compression pressure specification (Automatic de-comp. actuated)

| Standard | Limit | Difference |

| 1300-1700 kPa 13-17 kgf/cm² 185-242 psi | 1100 kPa 11 kgf/cm² 156 psi | 200 kPa 2 kgf/cm² 28 psi |

Low compression pressure can indicate any of the following conditions:

- Worn-down piston or piston rings

- Piston rings stuck in grooves

- Poor seating of valves

- Ruptured or otherwise defective cylinder head gasket

Overhaul the engine in the following cases:

- Compression pressure in one of the cylinders is 1100 kPa (11 kgf/cm², 156 psi) and less.

- Difference in compression pressure between two cylinders is 200 kPa (2 kgf/cm², 28 psi) and more.

- All compression pressure are below 1300 kPa (13 kgf/cm², 185 psi) even when they measure 1 100 kPa (11 kgf/cm², 156 psi) and more.

Compression test procedure

Notes:

- Before testing the engine for compression pressure, make sure that the cylinder head bolts are tightened to the specified torque values and valves are properly adjusted.

- Have the engine warmed up by idling before testing.

- Be sure that the battery used is in fully-charged condition.

|  |

Remove the parts concerned and test the compression pressure in the following manner.

Lift and support the fuel tank. (5-7)

Remove all the spark plugs. (2-6)

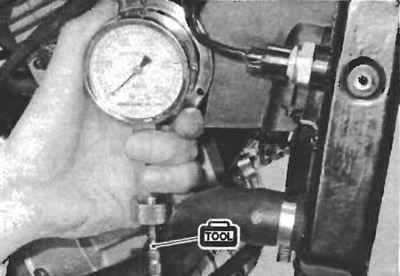

Fit the compression gauge in one of the plug holes, while taking care of the tight connection.

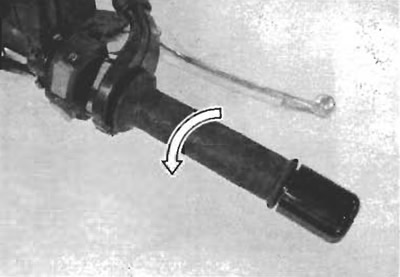

Keep the throttle grip in full-open position.

While cranking the engine a few seconds with the starter, and record the maximum gauge reading as the compression of that cylinder.

Repeat this procedure with an other cylinder.

- 09915-64512: Compression gauge

- 09913-10750: Adaptor