Note: The crankpin clearances are measured using "Plastigage" (Triumph part number 3880150-T0301). Do not turn the connecting rod and crankshaft during the clearance measurement as this will damage the "Plastigage".

2. Remove the big end cap from the journal to be checked.

3. Wipe the exposed areas of the crankpin, and the bearing face inside the cap.

4. Apply a thin smear of grease to the journal and a small quantity of silicone release agent to the bearing.

5. Trim a length of the Plastigage to fit across the journal. Fit the strip to the journal using the grease to hold the Plastigage in place.

6. Lubricate the threads of the bolt and under-head area with undiluted molybdenum disulphide grease. Refit the bearing and cap and tighten the big end bolts as described earlier.

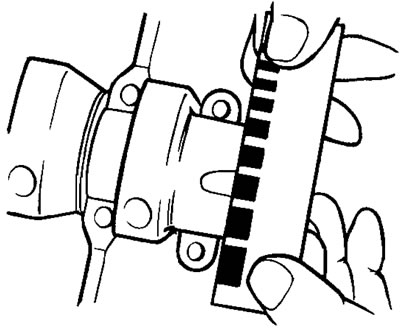

7. Release the bolts and remove the cap being measured. Using the gauge provided with the Plastigage kit, measure the width of the compressed Plastigage.

Checking the measured clearance

| Con rod big end bearing/crankpin clearance | |

| Standard | 0.065-0.035 mm |

| Service Limit | 0.100 mm |

Note: If the measured clearance exceeds the service limit, measure the crankpin diameter.

| Crankpin diameter | |

| Standard | 40.946-40.960 mm |

| Service limit | 40.922 mm |

Note: If any crankpin has worn beyond the service limit, the crankshaft must be replaced. Due to the advanced techniques used during manufacture, the crankshaft cannot be reground and oversize bearings are not available.

Connecting rod bearing selection

Note: Optimum running clearance is achieved by using selective big end bearings. For further information on bearing part number to colour cross-references, refer to the parts information system.

Select the correct big end bearing shell as follows:

1. Measure each crankpin diameter.

2. Select the correct bearings by matching the information found with the chart below.

Big end bearing selection chart

| Shell Colour | White | Red |

| Crankpin diameter | 40.960 to 40.954 | 40.953 to 40.946 |

For instance:

- Crankpin diameter — 40.958

- Required Bearing — White

Note: Repeat the measurements for all connecting rods and their respective crankpins. It is normal for the bearings selected to differ from one connecting rod to another.

Warning! Always confirm, using the Plastigage method, that the running clearance is correct before final assembly. Severe engine damage could resuit from incorrect clearance, resulting in loss of motorcycle control and an accident.