Note: Insufficient compression pressure will result in a loss of performance.

1. Measure:

- Valve clearance. Out of specification → Adjust. Refer to «Adjusting the valve clearance».

2. Start the engine, warm it up for several minutes, and then turn it off.

3. Remove:

- Ignition coils

- Spark plugs

Caution! Before removing the spark plugs, use compressed air to blow away any dirt accumulated in the spark plug wells to prevent it from falling into the cylinders.

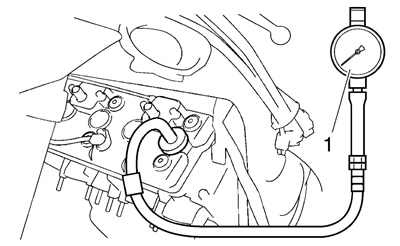

4. Install:

- Compression gauge "1"

- Extension

Compression gauge 90890-03081. Engine compression tester YU-33223.

5. Measure:

- Compression pressure. Out of specification → Refer to steps (c) and (d).

Compression pressure (at sea level):

- Minimum — 1290 kPa (12.90 kg/cm2 3, 12.90 bar, 183.5 psi)

- Standard — 1480 kPa (14.80 kg/cm2, 14.80 bar, 210.5 psi)

- Maximum — 1660 kPa (16.60 kg/cm2, 16.60 bar, 236.1 psi)

a. Set the main switch to "ON".

b. With the throttle wide open, crank the engine until the reading on the compression gauge stabilizes.

Warning! To prevent sparking, ground all spark plug leads before cranking the engine.

Note: The difference in compression pressure between cylinders should not exceed 100 kPa (1 kg/cm2, 1 bar, 14.22 psi).

c. If the compression pressure is above the maximum specification, check the cylinder head, valve surfaces and piston crown for carbon deposits. Carbon deposits → Eliminate.

d. If the compression pressure is below the minimum specification, pour a teaspoonful of engine oil into the spark plug bore and measure again. Refer to the following table.

Compression pressure (with oil applied into the cylinder)

| Reading | Diagnosis |

| Higher than without oil | Piston ring(s) wear or damage → Repair. |

| Same as without oil | Piston, valves, cylinder head gasket or piston possibly defective → Repair. |

6. Install:

- Spark plug

Spark plug — 13 Nm (1.3 m·kg, 9.4 ft·lb)

7. Install:

- Ignition coils