Torque wrench settings:

- Swinging arm spindle (1): 100 Nm (10.0 kg·m).

- Adjusting bush (2): 12 Nm (1.2 kg·m)

- Lockring (3): 35 Nm (3.5 kg·m)

- Rear screw (4): 22 Nm (2.2 kg·m)

- Linkages to swinging arm (5): 80 Nm (8.0 kg·m)

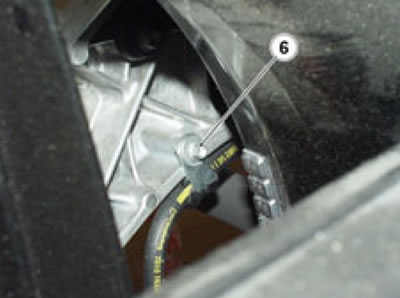

- Brake hose clips (6-7): 3 Nm (0.3 kg·m)

Fit the two washers to the spindle (1).

Smear the thread of the swinging arm spindle (1) with oil.

Warning! The tail section is heavy. An assistant will be required to perform the following operations. When working with an assistant, plan the whole procedure carefully together.

Locate the swinging arm to the frame.

Position the swinging arm so as to match the holes. At the same time, push the spindle (1) fully home from the left-hand side.

Correct adjustment of swinging arm spindle play is obtained by screwing the adjusting bush (2) all the way in and tightening an additional 1/4 turn.

Note. Make sure to have the special tool no. 8101945 (socket for swinging arm spindle adjustment) ready at hand.

Lock out bush (2) rotation and tighten the lockring (3) using the special tool.

Adjust the rear swinging arm; see 2.17.3.

Tighten the engine-to-frame mounting bolt (4).

Position the linkages to the swinging arm.

Insert the screw from the right-hand side.

Position the washer and tighten the nut (5).

Route the brake hose along the swinging arm.

Secure the brake hose inner clip with the screw (6).

Secure the brake hose outer clip with the screw (7).

Install the rear wheel; see 7.6.6.

Install the drive chain; see 7.13.2.

Lower the hoist arm.

Disconnect the slings from the frame.

Install the fuel tank; see 4.1.1.