Caution! Replace the valves one at a time. Do not mix the components. each valve must be inserted into its seat, which is marked prior to removal.

Caution!

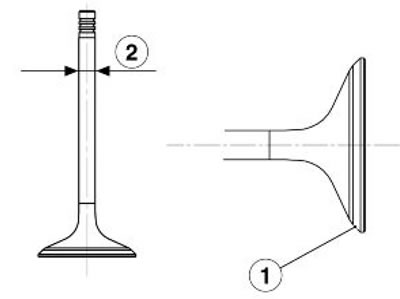

- The seat (1) on the valve head cannot be reground. if required, replace the valve.

- Grinding with abrasive paste is allowed; valve stem end regrinding is not allowed.

Clean off any combustion residues from the valves.

Check the seat (1) on the valve head with a ruler flush.

The surface of the seat must not be concave; replace the valve if necessary.

Check the clearance between the stem and the valve guide:

- inlet: 0.013 - 0.040 mm (0.00051 - 0.00157 in);

- limit: 0.080 mm (0.00315 in)

- outlet: 0.025 - 0.052 mm (0.00098 - 0.00205 in);

- limit: 0.100 mm (0.00394 in)

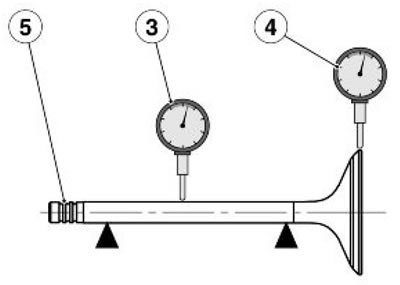

Check the valve eccentricity:

- valve stem (3) maximum eccentricity allowed: 0.05 mm (0.00197 in)

- valve head (4) maximum eccentricity allowed: 0.05 mm (0.00197 in)

Check that the fixing grooves (5) of the valve cotters are in proper conditions.

Valve springs

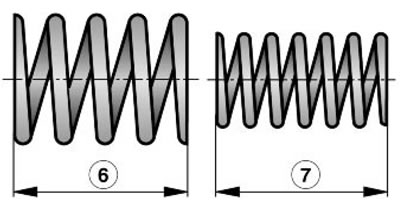

Carry out a measurement and a visual inspection of the valve springs for damage, distortion or loss of tension.

Measure the spring length at release position.

- Valve springs: minimum wear limit (6) 42.5 mm (1.673 in).

- Valve springs: minimum wear limit (7) 38 mm (1.496 in).