Before you dismantle any valve . components, note the clearance values for each valve. Remove the timing belt for the valve to be adjusted.

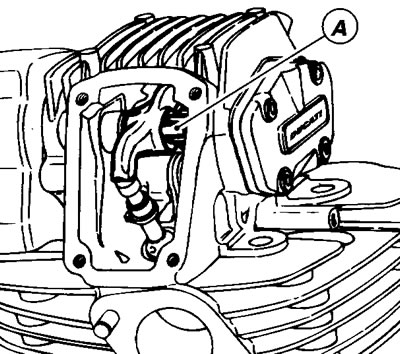

Remove the side spring (A) from the opening rocker pin and move the rocker to one side.

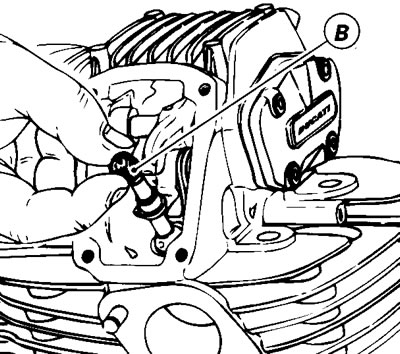

Remove the adjuster (B) from the end of the valve stem.

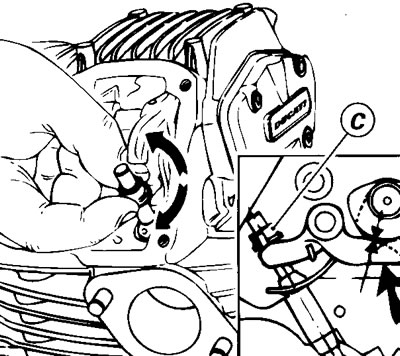

Using a screwdriver, push the closing rocker down to counteract the effect of the spring. If this is difficult, turn the camshaft by a few degrees.

Lower the end cap (C) and remove the two half rings.

Note. Care must be taken when handling the half rings to prevent them falling into the two oily holes in the head and down into the crankcase. During this operation the piston of the cylinder being adjusted must be at TDC to prevent the valve (which is not held by the spring) from falling into the cylinder.

Remove the closing adjuster cap (C) from the valve.

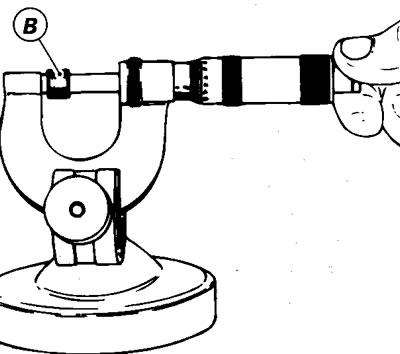

Using a 0-25 mm micrometer screw gauge fitted with the service pads as shown in the figure, check the thickness of the adjuster. Select an adjuster of the required size (adjuster scale from 5 to 9.6 mm).

Caution! Fitting an adjuster which is too thick will cause rapid rocker arm and camshaft wear.

Use a screwdriver, once again, to press down the closing (lower) rocker and counteract the spring.

Fit the new closing adjuster cap (C). Fit the new half rings and ensure that they seat correctly in the groove on the valve stem.

Check the clearance again. When you press the rocker down it should be possible to rotate the closing adjuster cap with your fingers.

If the cap is difficult to rotate, change it with a thinner one. If the valve clearance is too high, fit a thicker cap.

Next, select an opening adjuster (B) on the basis of the clearance measured and the corrections made on the closing adjuster. Two sets of opening adjusters are available: 2 mm to 4.10 mm thick (in steps of 0,05 mm); 4.20 to 4.70 mm (in steps 0.10 mm).

Fit the opening adjuster on the valve.

Position the opening rocker (B) and fit the spring (A) on the rocker arm pin.

Using a feeler gauge, check the clearance once again. If the clearance is not as specified, change the adjuster.

Fit and tension the timing belt as described in the section below. Turn the engine over several times. Move the piston to TDC on the compression stroke. Check the opening and closing clearances once again.

Carry out the above procedure on the two rocker arms of the other cylinder.