Notes:

- Valve clearance adjustment should be made on a cold engine, at room temperature.

- When the valve clearance is to be measured or adjusted, the piston must be at top dead center (TDC) on the compression stroke.

1. Remove:

- Rider and passenger seat. Refer to «General chassis».

- Fuel tank. Refer to «Fuel tank».

- Air filter case. Refer to «General chassis».

- Throttle body assembly. Refer to «Throttle bodies».

- Air cut-off valve. Refer to «Air induction system».

- Radiator

- Radiator fan motor. Refer to «Radiator».

2. Remove:

- Ignition coils

- Spark plugs

- Cylinder head cover

- Cylinder head cover gasket. Refer to «Camshafts».

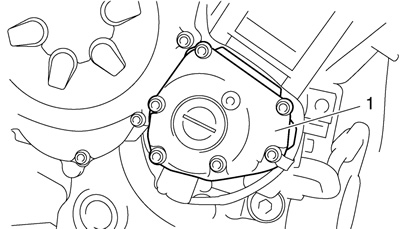

3. Remove:

- Pickup rotor cover "1".

Valve clearance. Out of specification → Adjust.

Valve clearance (cold):

- Intake valve 0.11-0.20 mm (0.0043-0.0079 in)

- Exhaust valve 0.21-0.25 mm (0.0083-0.0098 in)

a. Turn the crankshaft counterclockwise.

b. When piston #1 is at TDC on the compression stroke, align the TDC mark "a" on the pickup rotor with the crankcase mating surface "b".

Note. TDC on the compression stroke can be found when the camshaft lobes are turned away from each other.

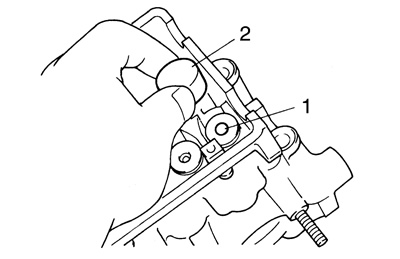

c. Measure the valve clearance with a thickness gauge "1".

Note: If the valve clearance is incorrect, record the measured reading.

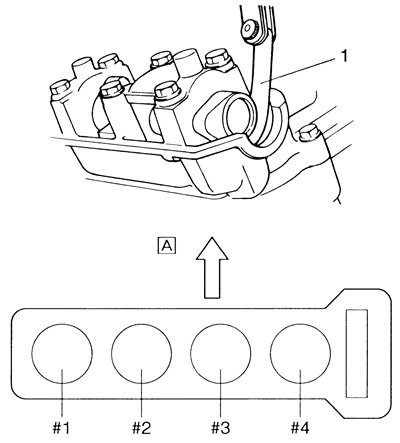

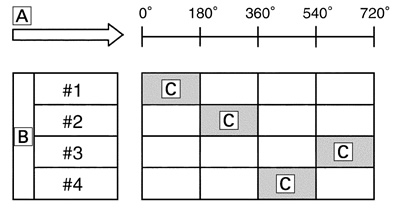

Measure the valve clearance in the following sequence.

Valve clearance measuring sequence. Cylinder #1 → #2 → #4 → #3

A. Front

d. To measure the valve clearances of the other cylinders, starting with cylinder #1 at TDC, turn the crankshaft counterclockwise as specified in the following table.

| Cylinder #2 | 180° |

| Cylinder #4 | 360° |

| Cylinder #3 | 540° |

A. Degrees that the crankshaft is turned counterclockwise; B. Cylinder; C. Combustion cycle

5. Remove: Camshaft.

Notes: Refer to «Camshafts». When removing the timing chain and camshafts, fasten the timing chain with a wire to retrieve it if it falls into the crankcase.

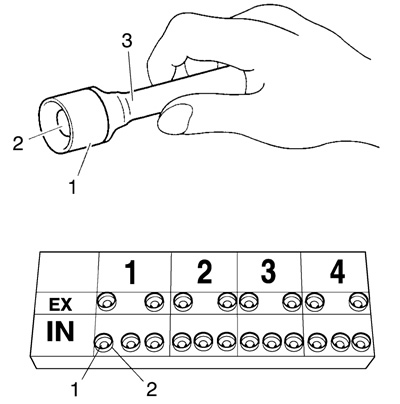

6. Adjust: Valve clearance.

a. Remove the valve lifter "1" and the valve pad "2" with a valve lapper "3".

Notes:

- Cover the timing chain opening with a rag to prevent the valve pad from falling into the crankcase.

- Make a note of the position of each valve lifter "1" and valve pad "2" so that they can be installed in the correct place.

b. Calculate the difference between the specified valve clearance and the measured valve clearance.

Example:

- Specified valve clearance = 0.11-0.20 mm (0.004-0.008 in)

- Measure valve clearance = 0.25 mm (0.010 in)

- 0.25 mm (0.010 in)-0.20 mm (0.008 in) = 0.05 mm (0.002 in)

c. Check the thickness of the current valve pad.

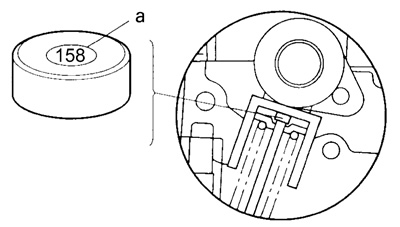

Note: The thickness "a" of each valve pad is marked in hundredths of millimeters on the side that touches the valve lifter.

Example: If the valve pad is marked "158", the pad thickness is 1.58 mm (0.062 in).

d. Calculate the sum of the values obtained in steps (b) and (c) to determine the required valve pad thickness and the valve pad number.

Example: 1.58 mm (0.062 in) + 0.05 mm (0.002 in) = 1.63 mm (0.064 in)

The valve pad number is 163.

e. Round off the valve pad number according to the following table, and then select the suitable valve pad.

| Last digit | Rounded value |

| 0, 1, 2 | 0 |

| 3, 4, 5, 6 | 5 |

| 7, 8, 9 | 10 |

Note: Refer to the following table for the available valve pads.

| Valve pad range | Nos. 150-240 |

| Valve pad thickness | 1.50-2.40 mm (0.0591-0.0945 in) |

| Available valve pads | 25 thicknesses in 0.05 mm (0.002 in) increments |

Example:

- Valve pad number = 163

- Rounded value = 165

- New valve pad number = 165

f. Install the new valve pad "1" and the valve lifter "2".

Notes:

- Lubricate the valve lifter with engine oil.

- Install the valve lifter and the valve pad in the correct place.

- The valve lifter must turn smoothly when rotated by hand.

g. Install the exhaust and intake camshafts, timing chain and camshaft caps.

Camshaft cap bolt 10 Nm (1.0 m·kg, 7.2 ft·lb).

Note: Refer to «Camshafts».

- Lubricate the camshaft bearings, camshaft lobes and camshaft journals.

- First, install the exhaust camshaft.

- Align the camshafts marks with the camshaft cap marks.

- Turn the crankshaft clockwise several full turns to seat the parts.

h. Measure the valve clearance again.

i. If the valve clearance is still out of specification, repeat all of the valve clearance adjustment steps until the specified clearance is obtained.

7. Install: All removed parts.

Note: For installation, reverse the removal procedure.