| DETECTED CONDITION | POSSIBLE CAUSE | ||

| C40 P0505 | H | ISC valve motor current is higher than the specified value. | ISC valve circuit shorted to BATT or ground circuit open |

| L | ISC valve motor circuit is open. | ISC valve circuit open or shorted to ground or BATT circuit open | |

| P0506 | Idle speed is lower than the desired idle speed. | W/Y or Lg wire open or short ISC valve is fixed Air curcuit clogged | |

| P0507 | Idle speed is higher than the desired idle speed. | W/Y or Dgr wire open or short Disconnected ISC valve hose | |

Caution: Be careful not to disconnect at least 3 seconds after ignition switch is turned to OFF. If the ECM coupler is disconnected within 3 seconds after ignition switch is turned to OFF, there is a possibility of an usual valve being written in ECM and causing an error of ISC valve operation.

Inspection

Step 1

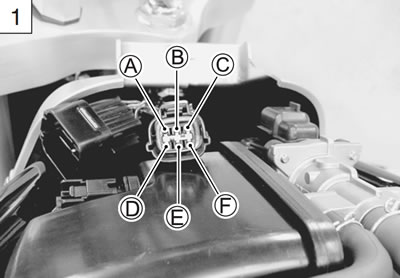

- 1) Remove the fuel tank. (6-3)

- 2) Turn the ignition switch OFF.

- 3) Check the ISC valve coupler for loose or poor contacts.

- 4) If OK, then check the ISC valve lead wire continuity.

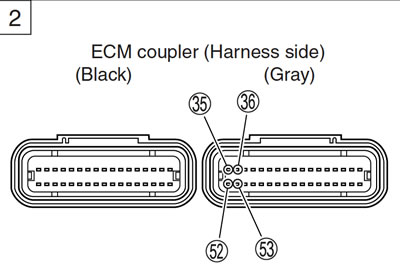

- 5) Disconnect the ISC valve coupler and ECM coupler. (5-37)

- 6) Check the continuity between terminals А and 53, terminals В and 16, terminals С and 36, terminals D and 52, terminals E and 16, and terminals F and 45.

Caution: When using the multi-circuit tester, do not strongly touch the terminal of the ECM coupler with a needle pointed tester probe to prevent the terminal damage or terminal bend.

- ISC valve wire continuity: Continuity (•)))

- 09900-25008: Multi-circuit tester set

- 09900-25009: Needle pointed probe set

- Tester knob indication: Continuity test (•)))

Is the continuity OK?

| YES | Go to Step 2. |

| NO | Lbl, W/Y, Dgr, R/Bl or Lg wire open. |

- 7) After repairing the trouble, clear the DTC using SDS tool. (5-26)

Step 2

- 1) Turn the ignition switch OFF.

- 2) Disconnect the ISC valve coupler.

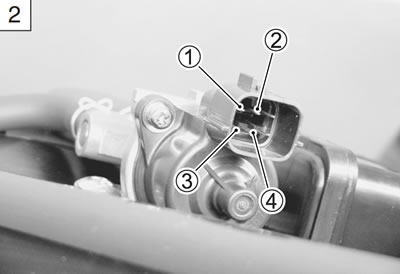

- 3) Check the continuity between terminals 1 and 3, terminals 2 and 4.

- ISC valve continuity: Approx. ∞ Ω (Infinity)

- (Terminal 1 - Terminal 3)

- (Terminal 2 - Terminal 4)

- 4) If OK, then measure the resistance between terminals 1 and 2, terminals 3 and 4.

- ISC valve resistance: Approx. 30±1.2 Ω at 20°C (68°F)

- (Terminal 1 - Terminal 3)

- (Terminal 2 - Terminal 4)

Is the resistance OK?

| YES | If wire is OK, intermittent trouble or faulty ECM. |

| NO | Replace the ISC valve with a new one. |

- 5) After repairing the trouble, clear the DTC using SDS tool. (5-26)

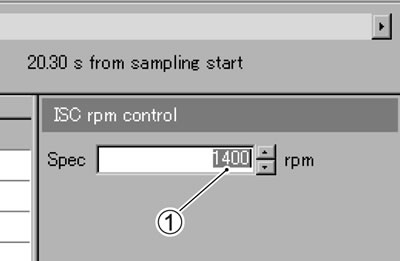

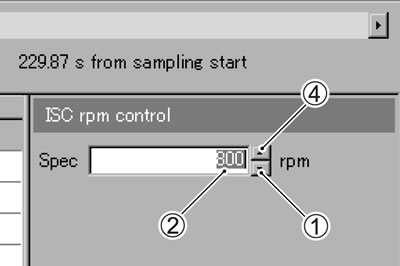

Active control inspection (ISC RPM Control)

Check 1

- 1) Set up the SDS tool. (Refer to the SDS operation manual for further details.)

- 2) Check that the engine is running.

- 3) Click the "Active control".

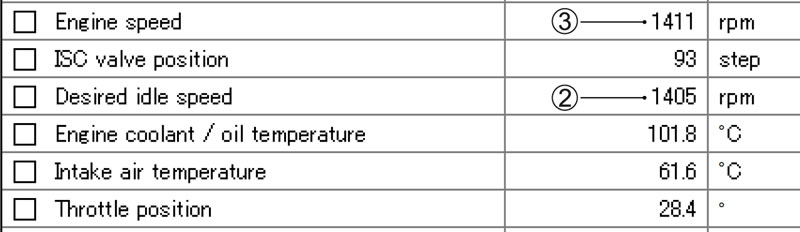

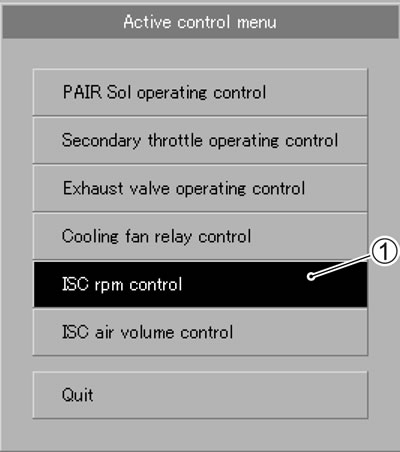

- 4) Click the "ISC rpm control" 1.

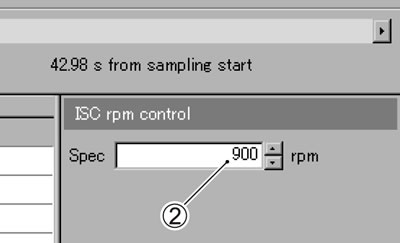

- 5) Check that the "Spec" 2 is 900 rpm.

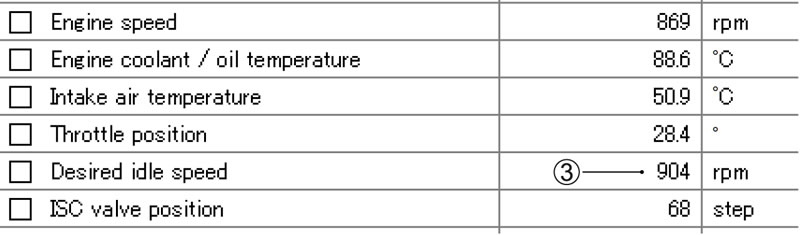

- 6) Check that the "Desired idle speed" 3 is 900 rpm.

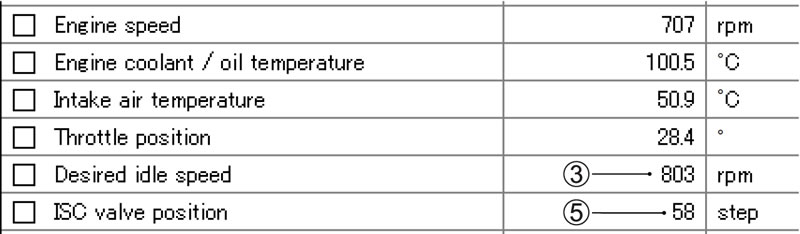

Check 2

- 1) Click the button 1 and decrease the "Spec" 2 to 800 rpm slowly.

- 2) Check that the "Desired idle speed" 3 is nearly equal to the "Spec" 2. At the same time, check that the number of steps in the ISC valve position decreases.

- 3) Click the button 4 and increase the "Spec" 2 slowly.

- 4) Check that the "Desired idle speed" 3 is nearly equal to the "Spec" 2. Also, check that the number of steps 5 in the ISC valve position increases.

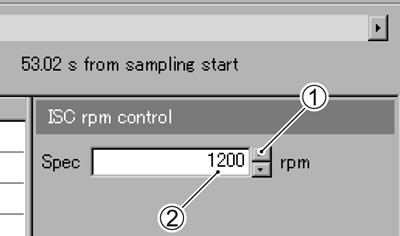

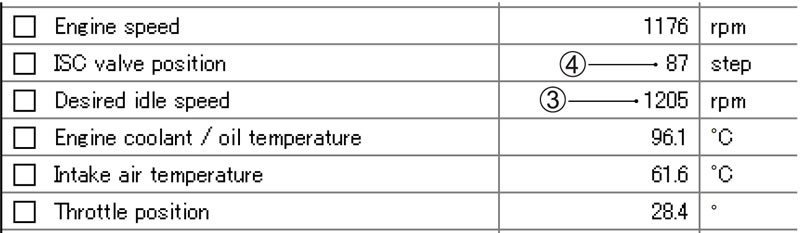

Check 3

- 1) Click the button 1 and increase the "Spec" 2 to 1 200 rpm slowly.

- 2) Check that the "Desired idle speed" 3 is nearly equal to the "Spec" 2. Also, check that the number of steps 4 in the ISC valve position increases.

Caution: Be careful not to increase the "Spec" to 1 500 rpm, or the "Engine speed" may reach the upper limit.