- Idle air fuel nozzle

- Main fuel jet

- Main air jet

- Air jet of idle system

- Fuel jet holes

- Float

- Needle valve

- Starting jet

- Gaskets and seals

- Throttle axis cuff

- Idle jet outlet and bypass holes

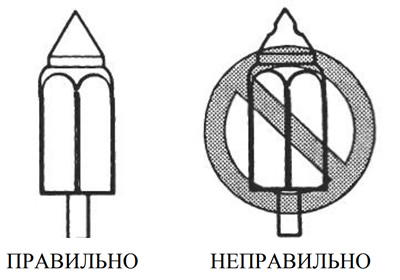

Checking the needle valve

If a foreign object gets between the needle valve and the valve seat, the valve will leak gasoline, causing the float chamber to overflow. If the valve seat and needle valve are worn beyond tolerance, the same thing can happen. Conversely, if the valve sticks, gasoline may not flow into the float chamber. Clean the float chamber and float mechanism parts using cleaner. If the needle valve is worn as shown in the picture, replace the needle valve along with the seat. Clean the fuel channel of the mixing chamber (I mean the fuel nozzle) compressed air.

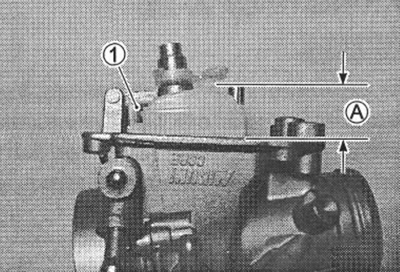

Adjusting the fuel level in the float chamber

To check the fuel level, turn the carburetor over and measure the distance «A» at the moment when «tongue» the float touches the needle valve.

Fold «tongue» float (1) to achieve the required distance (A).

Fuel level in the float chamber: 14.2±1.0 mm

09900-20102: Vernier caliper