Function

The pressure sensors (one per cylinder) are fundamental not only for the injection configuration at low and stabilised speeds, but also for checking the Ride by wire system: their signal is connected to a TORQUE CHAIN for checking the correct opening of the throttle valves.

Operating principle

Diaphragm sensor which translates the diaphragm position into electrical voltage when in contact with the intake air.

Level in wiring diagram: intake air temperature sensor

Location:

- on the vehicle: inside the filter casing

- connector: on the sensor

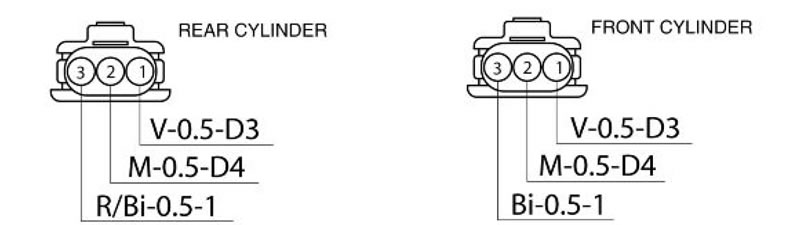

Pin-out:

1. Supply; 2. Ground connection; 3. Output signal

Axone: parameters

Front Cylinder Intake Pressure

- Example value: 1003 mbar

Pressure read by the front sensor.

Rear Cylinder Intake Pressure

- Example value: 1004 mbar

Pressure read by the rear sensor.

Front Cylinder estimated Intake Pressure

- Example value: 1003 mbar

Pressure estimated by the control unit according to the throttle position.

Rear Cylinder estimated Intake Pressure

- Example value: 1004 mbar

Pressure estimated by the control unit according to the throttle position.

Axone: electrical errors

Front cylinder air pressure sensor P0105 - short circuit to positive / open circuit, short circuit to negative.

Error cause

If shorted to positive: excessive voltage has been detected at PIN 34 of the VEHICLE connector.

If the circuit is open, shorted to negative: voltage equal to zero has been detected at PIN 34 of the VEHICLE connector.

Troubleshooting

If short circuit to positive, see that the parameter of the front Cylinder Intake Pressure on the diagnosis instrument reads approx. 1200 mbar; disconnect the large connector from the filter casing: if the value does not vary, it means that the cable is shorted between the filter casing connector and the control unit connector; restore the cable harness. If the value varies, reconnect the filter casing connector and disconnect the sensor connector: if the value does not vary, it means that the cable is shorted between the filter casing connector and the sensor connector; restore the cable harness. Replace the sensor if the value varies.

If the circuit is open, short circuit to negative, check filter casing large connector, the Marelli control unit connector and the sensor connector. If not OK, restore. If everything is OK, and with key set to OFF, check if there is continuity between the VEHICLE PIN 34 of the Marelli control unit and the sensor connector PIN 3: if there is no continuity, restore the cable harness. If there is continuity, check the cable earth insulation: if there is continuity to ground, restore the cable harness; if not, with key set to ON check that the voltage on sensor connector PIN 1 is approx. 5 V: if this is not correct, set the key to OFF and check continuity between the ENGINE connector PIN 15 and the sensor connector PIN 1: If not OK, restore the cable harness; if it is OK, replace the control unit. if there is 5V voltage at PIN 1, and with key set to ON, check the continuity to ground of the sensor connector PIN 3: If not OK, restore cable harness; if it is OK, replace the sensor.

Rear cylinder air pressure sensor P0106 - short circuit to positive / open circuit, short circuit to negative.

Error cause

If shorted to positive: excessive voltage has been detected at PIN 5 of the VEHICLE connector.

If the circuit is open, shorted to negative: voltage equal to zero has been detected at PIN 5 of the VEHICLE connector.

Troubleshooting

If short circuit to positive, see that the parameter of the front Cylinder Intake Pressure on the diagnosis instrument reads approx. 1200 mbar; disconnect the large connector from the filter casing: if the value does not vary, it means that the cable is short circuited between the filter casing connector and the control unit connector; restore the cable harness. If the value varies, reconnect the filter casing connector and disconnect the sensor connector: if the value does not vary, it means that the cable is short circuited between the filter casing connector and the sensor connector; restore the cable harness. Replace the sensor if the value varies.

If the circuit is open, short circuit to negative, check the filter casing large connector, the Marelli control unit connector and the sensor connector; If not OK, restore. If everything is OK, and with key set to OFF, check if there is continuity between the VEHICLE PIN 5 of the Marelli control unit and the sensor connector PIN 3: if there is no continuity, restore the cable harness. If there is continuity, check the cable earth insulation: if there is continuity to ground, restore the cable harness; if not, with key set to ON check that the voltage on sensor connector PIN 1 is approx. 5 V: if this is not correct, set the key to OFF and check continuity between the ENGINE connector PIN 15 and the sensor connector PIN 1: If not OK, restore the cable harness; if it is OK, replace the control unit. if there is 5V voltage at PIN 1, and with key set to ON, check the continuity to ground of the sensor connector PIN 3: If not OK, restore cable harness; if it is OK, replace the sensor.

Axone: logic errors

front cylinder air pressure sensor P0107 - signal not valid.

Error cause

According to the engine operation data (rpm, throttle, etc.) an average value for the intake pressure is estimated: if the value read deviates by a given percentage, this error is activated. The most frequent causes can be: abnormal resistance in the sensor circuit (for example, rusted terminals) or sensor with poor performance.

Troubleshooting

Check the filter casing large connector, the Marelli control unit connector and the sensor connector; if not OK, restore. If everything is OK, check that cable resistance between VEHICLE connector PIN 34 and sensor connector PIN 3 is a few tenths of an Ohm. If it is above that value, restore cable harness. Replace the sensor if it is correct.

rear cylinder air pressure sensor P0108 - signal not valid.

Error cause

According to the engine operation data (rpm, throttle, etc.) an average value for the intake pressure is estimated: if the value read deviates by a given percentage, this error is activated. The most frequent causes can be: abnormal resistance in the sensor circuit (for example, rusted terminals) or sensor with poor performance.

Troubleshooting

Check the filter casing large connector, the Marelli control unit connector and the sensor connector; if not OK, restore. If everything is OK, check that resistance between VEHICLE connector PIN 5 and sensor connector PIN 3 is a few tenths of an Ohm. If it is above that value, restore cable harness. Replace the sensor if it is correct.

Error for unexpected intake air in the front cylinder manifold P0210 - signal not valid.

Error cause

A small difference between the estimated pressure and the measured pressure has been detected: the measured pressure is higher than the estimated one (for example, cut or wrongly connected pipe between sensor and throttle body or a hole in the intake manifold).

Troubleshooting

Check the pneumatic system between the pressure sensor and the socket to read pressure on the throttle body; check that the intake manifold is in good conditions and the pressure reading hole is clean.

Error for unexpected intake air in the rear cylinder manifold P0211 - signal not valid.

Error cause

A small difference between the estimated pressure and the measured pressure has been detected: the measured pressure is higher than the estimated one (for example, cut or wrongly connected pipe between sensor and throttle body or a hole in the intake manifold).

Troubleshooting

Check the pneumatic system between the pressure sensor and the socket to read pressure on the throttle body; check that the intake manifold is in good conditions and the pressure reading hole is clean.

Estimation error for front cylinder intake manifold pressure P0215 - pressure too high/pressure too low.

Error cause

A substantial difference between the estimated pressure and the measured pressure has been detected (for example, the pipe between sensor and throttle body is fully detached/ clogged or squashed).

Troubleshooting

Check the pneumatic system between the pressure sensor and the socket to read pressure on the throttle body; check that the intake manifold is in good conditions and the pressure reading hole is clean: there is an evident defect in the intake and pressure reading systems.

Estimation error for rear cylinder intake manifold pressure P0216 - pressure too high/pressure too low.

Error cause

A substantial difference between the estimated pressure and the measured pressure has been detected (for example, the pipe between sensor and throttle body is fully detached/ clogged or squashed).

Troubleshooting

Check the pneumatic system between the pressure sensor and the socket to read pressure on the throttle body; check that the intake manifold is in good conditions and the pressure reading hole is clean: there is an evident defect in the intake and pressure reading systems.

Pressure too low at front cylinder manifold error P0217 - signal not valid.

A small difference between the estimated pressure and the measured pressure has been detected: the measured pressure is below the estimated one (for example, smeared throttle body).

Troubleshooting

Check the pneumatic system between the pressure sensor and the socket to read pressure on the throttle body; check that the intake manifold is in good conditions and the pressure reading hole is clean.

Pressure too low at rear cylinder manifold error P0218 - signal not valid.

Error cause

A small difference between the estimated pressure and the measured pressure has been detected: the measured pressure is below the estimated one (for example, smeared throttle body).

Troubleshooting

Check the pneumatic system between the pressure sensor and the socket to read pressure on the throttle body; check that the intake manifold is in good conditions and the pressure reading hole is clean.