This system consists of three circuits:

- Fuel circuit

- Air circuit

- Electrical circuit

|  |

Influence of the air-fuel mixture and of the advance

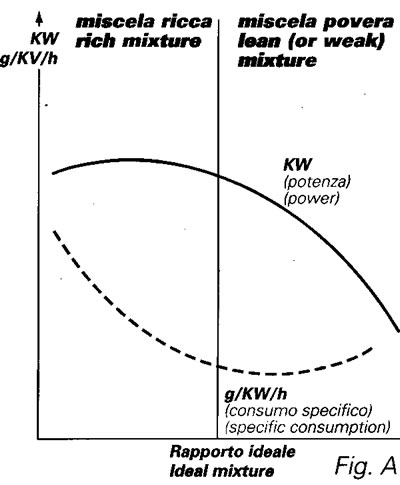

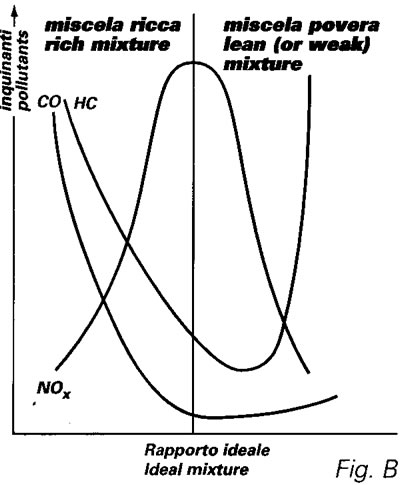

Correct use of the air-fuel mixture and of the advance is fundamental for optimal functioning of the engine. The air-fuel mixture is given by the ratio, in weight, air and fuel taken in by the engine: the ideal or stoichiometric ratio is that which establishes complete combustion. Excessive air or insufficient air give rise to, respectively, a lean (or weak) mixture or a rich mixture, which affect the power and the consumption (see fig. A), as well as emissions of exhaust gases (see fig. B).

Electronic control of the advance makes it possible to optimise the performance of the engine, the maximum power and the consumption and concentrations of exhaust pollutants.

Electronic control for the ignition advance and fuel supply allows for optimal functioning of the engine under all conditions of use (low temperature starts, tuning, engine with partial load).

Marelli injection-ignition system (I.A.W.)

The Weber injection-ignition system is the Alfa/N type, in which the engine speed and throttle position are used as main parameters for measuring the quantity of intake air; if the quantity of air is known, the quantity of fuel is dosed in accordance with the required mixture. Other sensors in the system (engine, atmospheric pressure, air temperature and water temperature sensors and idle trimmer) can be used to adjust the basic engine control strategy, as a function of operating conditions. The engine speed and the throttle angle also make it possible to calculate the optimal advance for all types of operating conditions. The quantity of air taken in by each cylinder, during each cycle, depends on the density of the air in the intake manifold, the cylinder capacity and the volumetric efficiency. The volumetric efficiency is measured experimentally on the engine for the entire functioning range (engine PPM and engine loading) and is stored in an Eprom map in the electronic unit. The injector control is sequential and timed, i.e. the two injectors are controlled in accordance with the intake sequence, while the injection can begin for each cylinder from the expansion phase to the intake phase already begun. The timing for the end of the injection is stored in an Eprom map in the electronic unit. The ignition is a static type inductive discharge ignition with control of the dwell in the power modules (built into the unit) and advance curves stored in the Eprom electronic unit.

Note. For testing the components and relative cabling of the injectionignition system, use the «MATHESIS" tester, following the indications in the manual supplied with it.