General

Deutsch Connectors feature a superior seal to protect electrical contacts from dirt and moisture in harsh environments. The connector also provides superior pin retention.

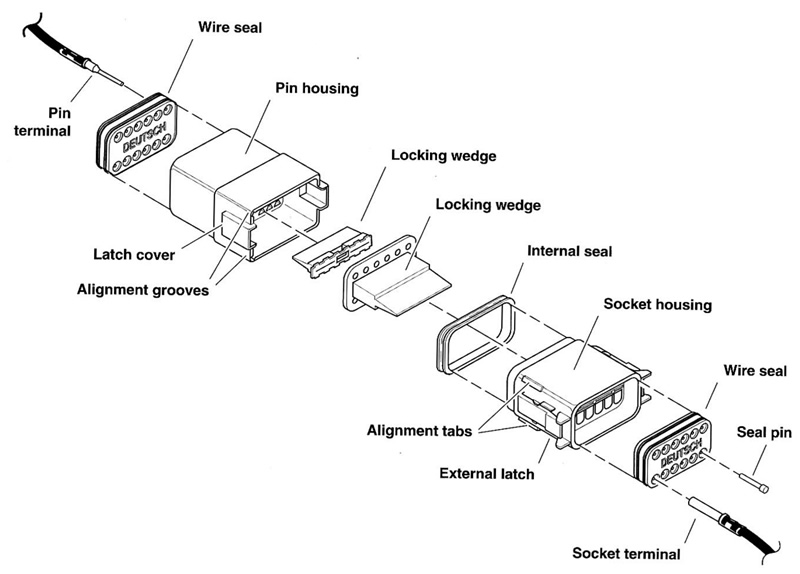

See Figure B-8. This 12-pin connector illustrates the various parts of the Deutsch connector. The following instructions may be followed for all 2-pin through 12-pin Deutsch connectors.

Figure B-8. 12-pin Deutsch connector (exploded view)

Socket housing: alignment tabs and/or external latch, secondary locking wedge, internal seal, wire seal, seal pin.

Note. Seal pins or plugs are installed in the wire seals of unused pin and socket locations. If removed, seal pins must be replaced to maintain the integrity of the environmental seal.

Pin housing: alignment grooves and/or external latch cover, attachment clip, secondary locking wedge, wire seal, seal pin.

Removing/disassembling

Attachment clips are attached to the pin housings of most connectors. The clips are then attached to T-studs on the motorcycle frame. T-studs give positive location to electrical connectors and wire harness. Consistent location reduces electrical problems and improves serviceability.

1. Push the connector to disengage small end of slot on attachment clip from T-stud. Lift connector off T-stud.

2. Depress the external latch(es) on the socket housing side and use a rocking motion to separate the pin and socket halves. Two-, three-, four- and six-pin Deutsch connectors have one external latch, while eight- and twelve-pin connectors have two, both of which must be pressed simultaneously to separate the connector halves.

Note. With few exceptions, the socket housing can always be found on the accessory side, while the pin side of the connector is connected to the wiring harness.

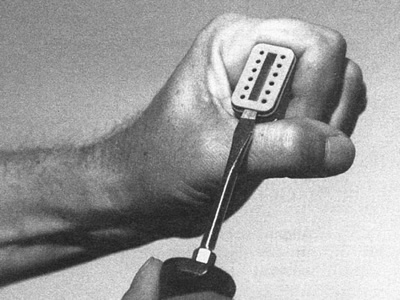

Figure B-6. Remove secondary locking wedge

Removing/installing sockets

1. See Figure B-7. Remove the secondary locking wedge. Insert the blade of a small screwdriver between the socket housing and locking wedge in line with the groove (in line with the pin holes if the groove is absent). Turn the screwdriver 90 degrees to pop the wedge up.

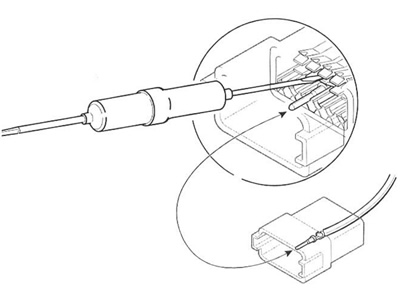

Figure B-7. Depress terminal latches/back out pins

2. See Figure B-8. Gently depress terminal latches inside socket housing and back out sockets through holes in rear wire seal.

Note. An ELECTRICAL TERMINAL CRIMP TOOL (Part No. HD-39965) is used to install Deutsch pin and socket terminals on wires. If new terminals must be installed, follow the instructions included with the crimping tool or see Crimping Instructions in this section.

Fit rear wire seal into back of socket housing, if removed. Grasp socket approximately 1.0 in. (25.4 mm) behind the contact barrel. Gently push sockets through holes in wire seal into their respective chambers. Feed socket into chamber until it "clicks" in place. Verify that socket will not back out of chamber; a slight tug on the wire will confirm that it is properly locked in place.

3. Install internal seal on lip of socket housing, if removed. Insert tapered end of secondary locking wedge into socket housing and press down until it snaps in place. The wedge fits into the center groove within the socket housing and holds the terminal latches tightly closed.

Notes:

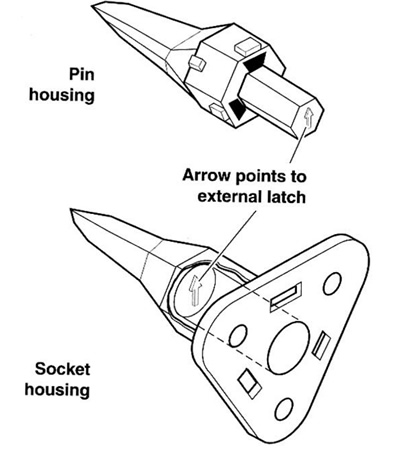

- While rectangular wedges do not require a special orientation, the conical secondary locking wedge of the 3-pin connector must be installed with the arrow pointing toward the external latch. See Figure B-9.

- If the secondary locking wedge does not slide into the installed position easily, verify that all terminals are fully installed in the socket housing. The lock indicates when terminals are not properly installed by not entering its fully installed position.

Figure B-9. Depress terminal latches/back out pins

Removing/installing pins

1. Remove the secondary locking wedge. Use the hooked end of a stiff piece of mechanics wire a needle nose pliers, or a suitable pick tool (Part No. HD-41475-100). See Figure B-10.

Figure B-10. Deutsch connector pick tool (Part No. HD-41475-100)

2. Gently depress terminal latches inside pin housing and back out pins through holes in wire seal.

Note. An ELECTRICAL TERMINAL CRIMP TOOL (Part No. HD-39965) is used to install Deutsch pin and socket terminals on wires. If new terminals must be installed, see Crimping Instructions in this section.

3. Fit wire seal into back of pin housing. Grasp crimped pin approximately 1.0 in. (25.4 mm) behind the contact barrel. Gently push pins through holes in wire seal into their respective numbered locations. Feed pin into chamber until it "clicks" in place. Verify that pin will not back out of chamber; a slight tug on the wire will confirm that it is properly locked in place.

4. Insert tapered end of secondary locking wedge into pin housing and press down until it snaps in place. The wedge fits in the center groove within the pin housing and holds the terminal latches tightly closed.

Notes:

- While rectangular wedges do not require a special orientation, the conical secondary locking wedge of the 3-pin connector must be installed with the arrow pointing toward the external latch. See Figure B-9.

- If the secondary locking wedge does not slide into the installed position easily, verify that all terminals are fully installed in the pin housing. The lock indicates when terminals are not properly installed by not entering its fully installed position.

Figure B-11. Attachment clip installation

Assembling/installing

1. Insert socket housing into pin housing until it snaps in place. Two-, three-, four- and six-pin Deutsch connectors have one external latch on the socket half of the connector. To fit the halves of the connector together, the latch on the socket side must be aligned with the latch cover on the pin side.

For those connectors with two external latches (8-pin and 12-pin), a different system is used to prevent improper assembly. Align the tabs on the socket housing with the grooves on the pin housing. Push the connector halves together until the latches "click." If latches do not click (latch), press on one side of the connector until that latch engages, then press on the opposite side to engage the other latch.

Note. Deutsch connectors are color coded for location purposes. Those connectors associated with left side accessories, such as the front and rear left turn signals, are gray. All other connectors, including those associated with right side accessories, are black.

If it should become necessary to replace a plug or receptacle, please note that the 8-pin and 12-pin gray and black connectors are not interchangeable. Since location of the alignment tabs differ between the black and gray connectors, plugs or receptacles must be replaced by those of the same color. If replacing both the socket and pin halves, then the black may be substituted for the gray, and vice versa. The socket and pin halves of all other connectors are interchangeable, that is, the black may be mated with the gray, since the alignment tabs are absent and the orientation of the external latch is the same.

Crimping instructions

1. See Figure B-12. Squeeze the handles to cycle the crimp tool to the fully open position.

Figure B-12. Deutsch crimping procedure

2. Raise locking bar by pushing up on bottom flange. With the crimp tails facing upward and the rounded side of the contact barrel resting on the concave split level area of the crimp tool, insert contact (socket/pin) through middle hole of locking bar.

3. Release locking bar to lock position of contact. If the crimp tails are slightly out of vertical alignment, the crimp tool automatically rotates the contact so that the tails face straight upward. When correctly positioned, the locking bar fits snugly in the space between the contact band and the core crimp tails.

4. Strip lead removing 5/32 in. (4 mm) of insulation. Insert wires between crimp tails until ends make contact with locking bar. Verify that wire is positioned so that short pair of crimp tails squeeze bare wire strands, while long pair folds over insulation material.

5. Squeeze handle of crimp tool until tightly closed. Tool automatically opens when the crimping sequence is complete. Raise up locking bar and remove contact.

6. Inspect the quality of the core and insulation crimps. Distortion should be minimal.