Disassembly

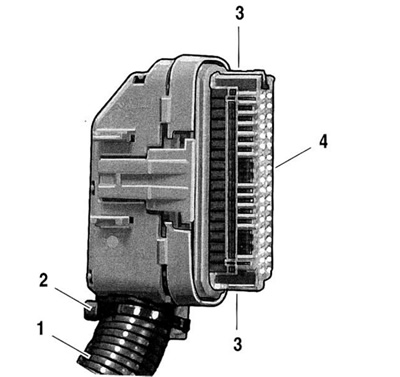

1. See Figure B-23. Depress tabs (3) on the sides of connector and remove clear plastic cover (4).

Figure B-23. ECM connector: 1. Conduit; 2. Cable strap; 3. Tabs; 4. Clear plastic cover

2. Remove cable strap (2).

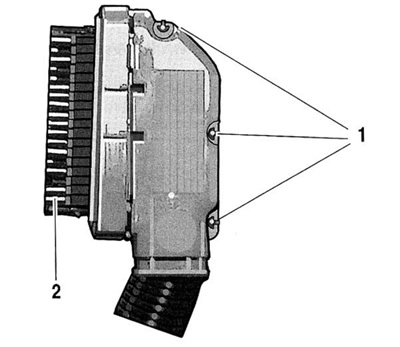

3. See Figure B-24. Pry three tabs to separate connector halves.

Figure B-24. Connector tabs

4. Push on desired wire from back of connector to expose wire terminal.

Note. A series of Packard Electrical Terminal Crimp Tools are available to install Packard socket terminals on wires. If new terminals must be installed, see CRIMPING INSTRUCTIONS below.

Assembly

1. Push wire into correct hole until terminal is seated.

Note. In next step be sure wires are not pinched while mating connector halves.

2. See Figure B-23. Mate connector halves making sure wires are not pinched and end of wire conduit (1) is inside connector halves.

3. Install new cable strap on end of connector.

4. Install clear plastic cover over terminals.

Crimping instructions

1. Strip wire lead removing 5/32 in. (4 mm) of insulation.

2. Compress handles until ratchet automatically opens.

Note. Always perform core crimp before insulation/seal crimp.

3. Determine the correct dye or nest for the core crimp by checking with the appropriate crimp table.

Note. When the word "TIP" appears in the Crimp Table, use the tip of the tool specified to perform the core crimp procedure. See Figure B-21.

4. Lay the back of the core crimp tails on the appropriate nest. Be sure the core crimp tails are pointing towards the forming jaws.

5. Gently apply pressure to handles of tool until crimpers slightly secure the core crimp tails.

6. Insert stripped wire between crimp tails. Verify that wire is positioned so that short pair of crimp tails squeeze bare wire strands, while long pair folds over insulation or seal material.

7. Squeeze handle of crimp tool until tightly closed. Tool automatically opens when the crimping sequence is complete.

8. Determine the correct dye or nest for the insulation/seal crimp.

9. Lay the back of the insulation/seal crimp tails on the appropriate nest. Be sure the insulation/seal crimp tails are pointing towards the forming jaws.

10. Squeeze handle of crimp tool until tightly closed. Tool automatically opens when the crimping sequence is complete.

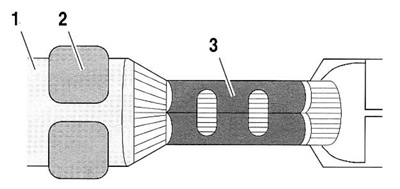

11. See Figure B-22. Inspect the quality of the core (3) and insulation/seal (2) crimps. Distortion should be minimal.

Figure B-25. Packard terminal crimp tools

Figure B-26. Inspect core and insulation/seal crimps: 1. Insulation; 2. Insulation crimp; 3. Core crimp

Table B-3. Packard terminal crimp tools

| SPECIFICATION | PACKARD 115 | PACKARD 271 |

| Part No. | HD-38125-8 | HD-38125-7 |

| Type of Crimp | Non-sealed terminals, butt splices | Non-sealed terminals |

| Dye/nests | F-G | A-E |