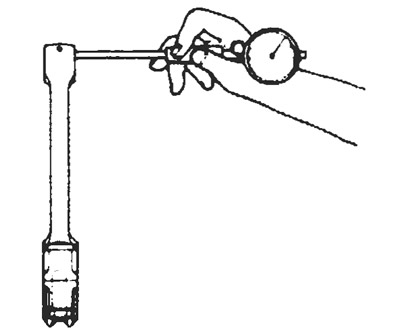

Conrod small end I.D.

Using a small bore gauge, measure the inside diameter of the conrod small end.

Conrod small end I.D.

- Service Limit: 20.040 mm (0.7890 in)

- 09900-20602: Dial gauge (1/1 000 mm, 1 mm)

- 09900-22403: Small bore gauge (18-35 mm)

If the inside diameter of the conrod small end exceeds the limit, replace the conrod.

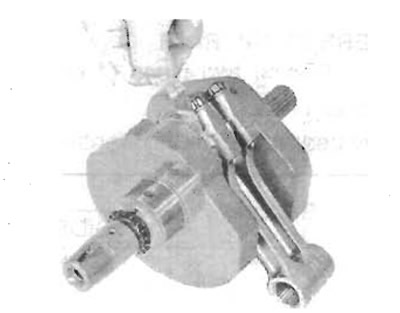

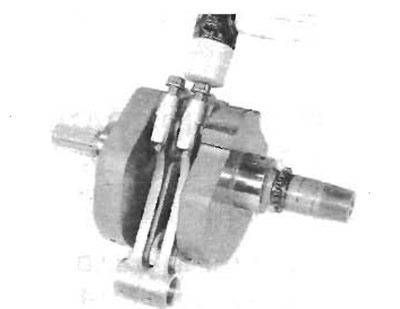

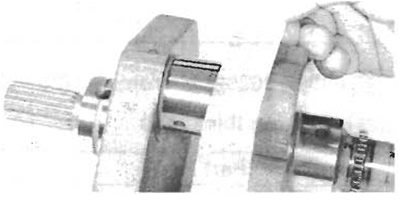

Conrod big end side clearance

Check the conrod side clearance by using a thickness gauge.

If the clearance exceeds the limit, replace conrod or crankshaft.

Conrod big end side clearance:

- Service Limit: 0.50 mm (0.020 in)

- 09900-20803: Thickness gauge

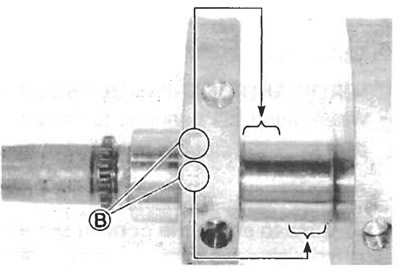

Conrod big end width

Check the conrod big end width.

Conrod big end width:

- Standard: 20.95-21.00 mm (0.825-0.827 in)

- 09900-20205: Micrometer (0-25 mm)

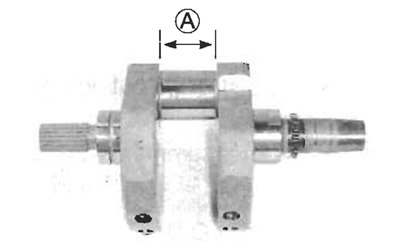

Crank pin width

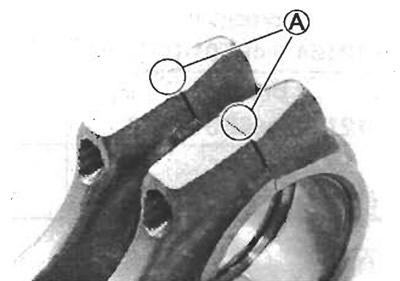

Check the crank pin width (A).

Crank pin width:

- Standard: 42.17-42.22 mm (1.660-1.662 in)

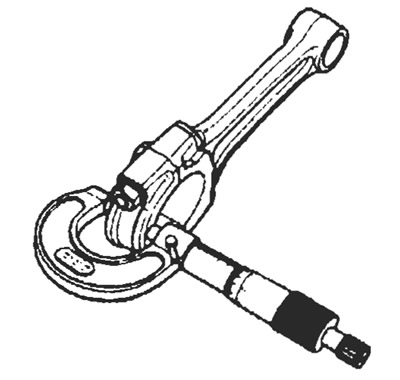

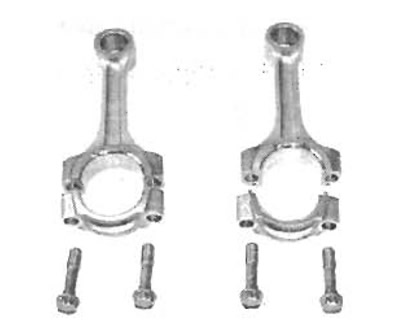

Conrod removal and bearing inspection

Loosen the bearing cap bolts, and tap the bearing cap bolt lightly with plastic hammer to remove the bearing cap.

Remove the conrods, and mark them to identify the cylinder position.

Inspect the bearing surfaces for any sign of fusion, pitting, burn, or flaws. If any, replace them with a specified set of bearings.

Conrod-crank pin bearing selection

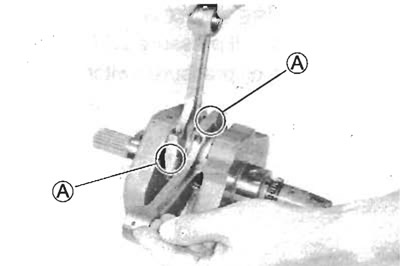

Place the plastigauge axially along the crank pin, avoiding the oil hole, at TDC or BDC side as shown.

- 09900-22301: Plastigauge

- 09900-22302: Plastigauge

Tighten the conrod cap bolts to the specified torque, in two stages. (3-57)

Caution! Never rotate the crankshaft or conrod when a piece of plastigauge is installed.

Remove the bearing caps and measure the width of the compressed plastigauge using the envelope scale. This measurement should be taken at the widest part of the compressed plastigauge.

Conrod big end oil clearance:

- Standard: 0.032-0.056 mm (0.0013-0.0022 in)

- Service Limit: 0.080 mm (0.0031 in)

If the oil clearance exceeds the service limit, select the specified bearings from the bearing selection table.

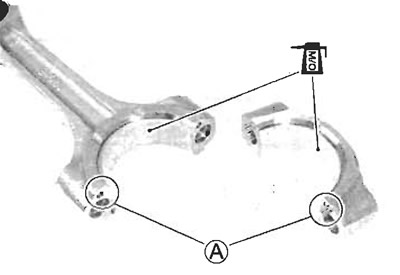

Check the corresponding conrod LD. code numbers ("1" or "2") (A).

Check the corresponding crank pin O.D. code numbers ("1", "2" or "3") (B).

Bearing selection table

| Crank pin O.D. (B) | ||||

| Code | 1 | 2 | 3 | |

| Conrod I.D. (A) | 1 | Green | Black | Brown |

| 2 | Black | Brown | Yellow | |

Conrod I.D.

| Code | I.D. specification |

| 1 | 41.000 - 41.008 mm (1.6142 - 1.6145 in) |

| 2 | 41.008 - 41.016 mm (1.6145 - 1.6148 in) |

Crank pin O.D.

| Code | O.D. specification |

| 1 | 37.992 - 38.000 mm (1.4957 - 1.4961 in) |

| 2 | 37.984 - 37.992 mm (1.4954 - 1.4957 in) |

| 3 | 37.976 - 37.984 mm (1.4951 - 1.4954 in) |

- 09900-20202: Micrometer (25-50 mm)

Bearing thickness

| Color (Part No.) | Thickness |

| Green (12164-46E01-0A0) | 1.480 - 1.484 mm (0.0583 - 0.0584 in) |

| Black (12164-46E01-0B0) | 1.484 - 1.488 mm (0.0584 - 0.0586 in) |

| Brown (12164-46E01-0C0) | 1.488 - 1.492 mm (0.0586 - 0.0587 in) |

| Yellow (12164-46E01-ODO) | 1.492 - 1.496 mm (0.0587 - 0.0589 in) |

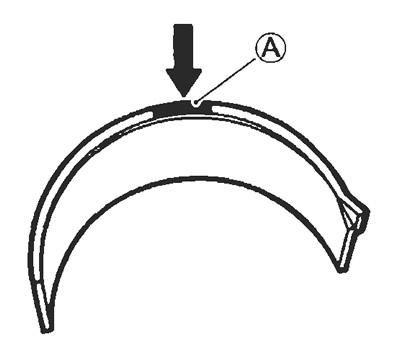

(A) Color code

Caution! The bearings must be replaced as a set.

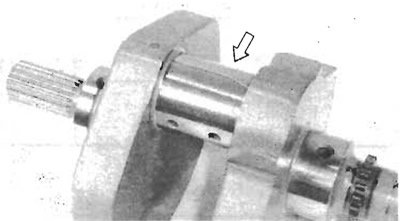

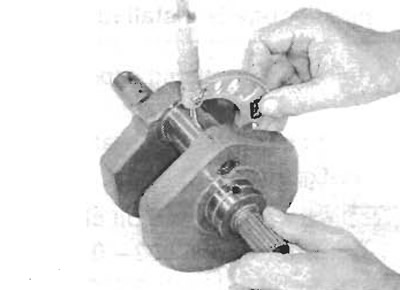

Conrod and bearing reassembly

When fitting the bearings to the bearing cap and conrod, be sure to fix the stopper part (A) first and press in the other end.

Caution! Be sure to clean the conrod big end.

Apply MOLYBDENUM OIL SOLUTION to the crank pin and bearing surface.

- Molybdenum oil solution

When fitting the conrods on the crankshaft, make sure that LD. codes (A) of the conrods face each cylinder intake valve sides.

Apply engine oil to the thread and flange of the bearing cap bolts.

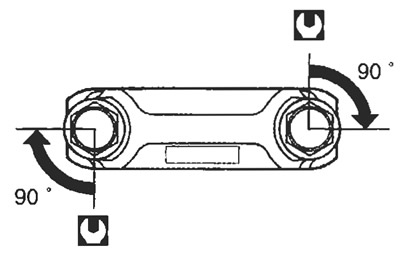

Tighten the bearing cap bolt as following two steps.

Conrod bearing cap bolt:

- (Initial): 21 N·m (2.1 kgf·m, 15.0 lb·ft)

- (Final): After tightening the bolts to the above torque, tighten them 1/4 of a turn (90°).

Apply engine oil to the conrod big end side surfaces.

Check the conrod movement for smooth turning.