Triumph:

Motorcycle engine lube system Triumph 765 R/RS 4 (Street Triple, 2017-2024)

See this section in russian language

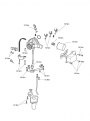

Oil pump/water pump, gears and heat exchanger

Exploded view - oil pump/water pump, gears and heat exchanger

Exploded view - oil pump/water pump, gears and heat exchanger

Oil circuit diagram

Oil circuit Oil is collected from the sump and is drawn through a mesh strainer into the oil pump rotor. The oil pump is fitted with a single pumping rotor which supplies pressurised oil to the lubrication circuit via the oil pressure relief valve....

Oil circuit Oil is collected from the sump and is drawn through a mesh strainer into the oil pump rotor. The oil pump is fitted with a single pumping rotor which supplies pressurised oil to the lubrication circuit via the oil pressure relief valve....

Heat exchanger

The heat exchanger is used to transfer heat from the engine oil into the coolant. Filtered oil is delivered to the heat exchanger via an opening (1) where it is circulated through the heat exchanger core. Coolant is pumped through a similar opening...

The heat exchanger is used to transfer heat from the engine oil into the coolant. Filtered oil is delivered to the heat exchanger via an opening (1) where it is circulated through the heat exchanger core. Coolant is pumped through a similar opening...

Engine oil — specification

Use semi or fully synthetic 10W/40 or 10W/50 motorcycle engine oil which meets specification API SH (or higher) and JASO MA, such as Castrol Power 1 Racing 4T, sold as Castrol Power RS Racing 4T in some countries. Triumph recommends the fully...

Use semi or fully synthetic 10W/40 or 10W/50 motorcycle engine oil which meets specification API SH (or higher) and JASO MA, such as Castrol Power 1 Racing 4T, sold as Castrol Power RS Racing 4T in some countries. Triumph recommends the fully...

Oil level inspection

In order for the engine, transmission, and clutch to function correctly, maintain the engine oil at the correct level, and change the oil and oil filter in accordance with scheduled maintenance requirements. Warning! Motorcycle operation with...

In order for the engine, transmission, and clutch to function correctly, maintain the engine oil at the correct level, and change the oil and oil filter in accordance with scheduled maintenance requirements. Warning! Motorcycle operation with...

Oil and oil filter change

Warning! Prolonged or repeated contact with engine oil can lead to skin dryness, irritation and dermatitis. In addition, used engine oil contains potentially harmful contamination which can cause cancer. Wear suitable clothing and avoid skin...

Warning! Prolonged or repeated contact with engine oil can lead to skin dryness, irritation and dermatitis. In addition, used engine oil contains potentially harmful contamination which can cause cancer. Wear suitable clothing and avoid skin...

Oil pump — removal

Warning! If the engine has recently been running, the engine oil will be hot to the touch. Contact with the hot oils may cause damage to exposed skin. To avoid skin damage, do not touch hot oil. Warning! Prolonged or repeated contact with engine oil...

Warning! If the engine has recently been running, the engine oil will be hot to the touch. Contact with the hot oils may cause damage to exposed skin. To avoid skin damage, do not touch hot oil. Warning! Prolonged or repeated contact with engine oil...

Oil pump — disassembly

1. Release the fixing and remove the drive sprocket and spacer washer. 1. Oil pump; 2. Spacer washer; 3. Drive sprocket; 4. Fixing 2. Release the three fixings and withdraw the oil pump cover. 1. Oil pump cover; 2. Fixings

1. Release the fixing and remove the drive sprocket and spacer washer. 1. Oil pump; 2. Spacer washer; 3. Drive sprocket; 4. Fixing 2. Release the three fixings and withdraw the oil pump cover. 1. Oil pump cover; 2. Fixings

Oil pump — inspection

Caution! If any part of the oil pump is found to be outside the service limit, the complete pump must be replaced. Severe engine damage may result from the continued use of a faulty oil pump. Rotor tip clearance 1. Measure the rotor tip clearance...

Caution! If any part of the oil pump is found to be outside the service limit, the complete pump must be replaced. Severe engine damage may result from the continued use of a faulty oil pump. Rotor tip clearance 1. Measure the rotor tip clearance...

Oil pump — assembly

1. If all clearances are within service limits, liberally apply clean engine oil to all internal components and refit the oil pump cover. Refit the fixings and tighten to 12 Nm. 2. If any clearance measured is outside the service limits, renew the...

1. If all clearances are within service limits, liberally apply clean engine oil to all internal components and refit the oil pump cover. Refit the fixings and tighten to 12 Nm. 2. If any clearance measured is outside the service limits, renew the...

Oil pump — installation

Caution! Before fitting the oil pump to the crankcase ensure the pump internal surfaces have been wetted with clean engine oil. The pump may fail to pick-up oil from the sump if the surfaces have not been wetted. This will cause the engine to run...

Caution! Before fitting the oil pump to the crankcase ensure the pump internal surfaces have been wetted with clean engine oil. The pump may fail to pick-up oil from the sump if the surfaces have not been wetted. This will cause the engine to run...

Heat exchanger — removal

Warning! Make sure the motorcycle is stabilised and adequately supported. A correctly supported motorcycle will help prevent it from falling. An unstable motorcycle may fall, causing injury to the operator or damage to the motorcycle. Warning! If...

Warning! Make sure the motorcycle is stabilised and adequately supported. A correctly supported motorcycle will help prevent it from falling. An unstable motorcycle may fall, causing injury to the operator or damage to the motorcycle. Warning! If...

Heat exchanger — installation

1. Fit a new seal for the heat exchanger to the lower crankcase. 1. Seal; 2. Lower crankcase 2. Fit the heat exchanger to the crankcase and tighten its fixings to 10 Nm. 3. Fit the coolant hose to the heat exchanger and secure with the coolant hose...

1. Fit a new seal for the heat exchanger to the lower crankcase. 1. Seal; 2. Lower crankcase 2. Fit the heat exchanger to the crankcase and tighten its fixings to 10 Nm. 3. Fit the coolant hose to the heat exchanger and secure with the coolant hose...

Low oil pressure warning light switch — removal

Warning! Make sure the motorcycle is stabilised and adequately supported. A correctly supported motorcycle will help prevent it from falling. An unstable motorcycle may fall, causing injury to the operator or damage to the motorcycle. The low oil...

Warning! Make sure the motorcycle is stabilised and adequately supported. A correctly supported motorcycle will help prevent it from falling. An unstable motorcycle may fall, causing injury to the operator or damage to the motorcycle. The low oil...

Low oil pressure warning light switch — installation

1. Incorporating a new copper washer, fit the switch and tighten to 13 Nm. 2. Refit the electrical connection. Perform the following operations: Battery - installation Seat - installation

1. Incorporating a new copper washer, fit the switch and tighten to 13 Nm. 2. Refit the electrical connection. Perform the following operations: Battery - installation Seat - installation

Similar subsections of other motorcycle models

Lube system motorcycle Kawasaki ZX-6R ZX600-J1/J2 (2000-2002, 3 generation)

- Information for owner

- Introduction to manual

- Engine and systems

- Engine repair

- Fuel and control system

- Lubrication system

- Cooling system

- Transmission

- Running gear and frame

- Frame and hinged elements

- Front suspension and handlebar

- Rear suspension

- Brake system

- Wheels and tires

- Electric equipment

- Equipment and devices

- Starting and charging system

- Electrical circuits

Aprilia: RS-series Shiver (map) BMW: F-series R-series K-series (map) Ducati: ST series Monster (map) Harley: Street Sportster V-Rod (map) Honda: Africa Twin CB series VTX series (map) Kawasaki: ZX-6R Versys Vulcan (map) Suzuki: DR-Z V-Strom Boulevard (map) Triumph: Rocket Street Triple Tiger (map) Yamaha: Fazer DragStar R1 (map)