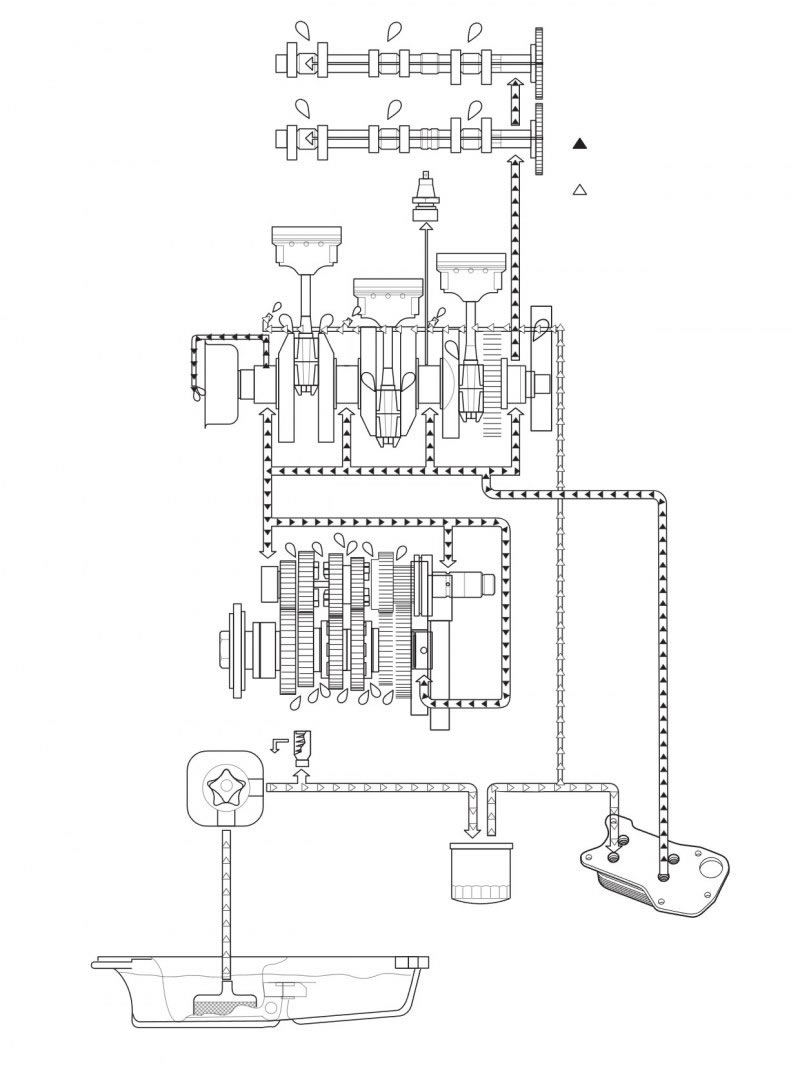

Oil circuit

Oil is collected from the sump and is drawn through a mesh strainer into the oil pump rotor. The oil pump is fitted with a single pumping rotor which supplies pressurised oil to the lubrication circuit via the oil pressure relief valve. The relief valve is set to open at 5.1 bar (75 lb/in²) and when open, returns high pressure oil direct to the sump.

The pressurised oil is delivered to the outside rim of the oil filter, where it is filtered by passing through the filter membrane. Filtered oil is then fed into the water heat exchanger (mounted on the front of the engine), where it is cooled.

After the oil has passed through the oil filter and oil cooler, it is distributed around the engine:

- Oil is delivered to the crankshaft main bearings and, via drillings in the crankshaft, to the big end bearings.

- Spray jets located in the upper crankcase, near the base of the barrel, lubricate the pistons and connecting rod small ends. These jets are fed oil from the oil gallery before the oil goes through the water heat exchanger.

- A low oil pressure warning light switch is also located in the upper crankcase gallery.

- Some oil is sent directly to the cylinder head via an internal gallery. Oil that arrives at the cylinder head is fed to both cams via a gallery in the cylinder head casting that delivers oil directly to the sprocket end of the camshafts. Oil is then fed through the hollow camshafts to the other camshaft bearings, the tappet buckets and the valves.

- Oil is fed to the gearbox via internal oil pipes and drillings that supply oil directly to the end of each shaft. Oil is circulated along the gearbox shafts to exit holes that feed directly to the bearings, gears and selectors.

- Oil is also fed to the alternator to aid cooling of the alternator components. The oil is taken from the crankshaft oil feed and directed to the alternator via a drilling in the bolt that secures the alternator rotor to the crankshaft.