Front wheel bearings

Carry out the check with the bearings fitted on the wheel.

Caution! Check that all parts are in good condition, especially those listed as follows.

Rotation check

Manually rotate the inside ring of each bearing. Rotation must be constant, smooth and noiseless.

If one or both bearings do not fall within the control parameters:

Replace both wheel bearings.

Radial and axial clearance check

Check the radial and axial clearance.

- Axial clearance: a minimum axial clearance is allowed.

- Radial clearance: none.

If one or both bearings do not fall within the control parameters:

Replace both wheel bearings.

Caution!

- Always replace both bearings.

- Always replace the bearings with others of the same type.

Gaskets

Check that the gaskets are in good conditions; replace them if they show signs of damage or excessive wear.

Caution!

- Always replace both gaskets.

- Always replace the gaskets with others of the same type.

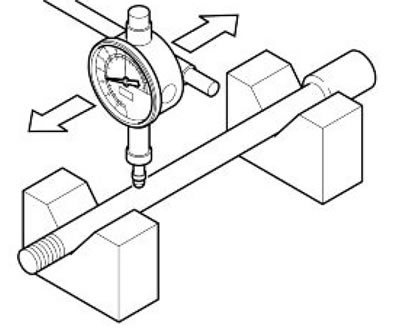

Wheel spindle

Use a dial gauge to check the wheel spindle eccentricity. Replace the wheel spindle if the eccentricity exceeds the limit value.

Characteristic:

- Maximum eccentricity: 0.25 mm (0.0098 in)

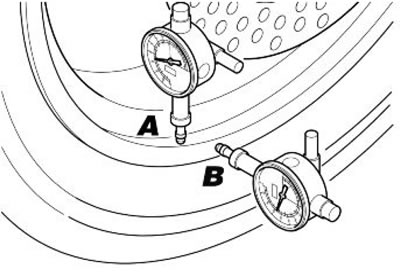

Using a dial gauge, check that the radial (A) and the axial (B) eccentricities of the rim do not exceed the limit value. An excessive eccentricity is usually caused by worn or damaged bearings. Replace the rim if, after replacing the bearings, the value is not within the specified limit.

Characteristic:

- Maximum radial and axial eccentricity: 2 mm (0.0079 in)