Removing

1. Remove the pendulum spacer.

2. Pry the oil seal with a slotted screwdriver and press it out of the mounting hole.

3. Remove the oil seal.

4. Remove the bearing circlip with special pincers.

5. Similarly, paragraphs 2-4 (see above) remove the oil seal and retaining ring on the other side of the pendulum.

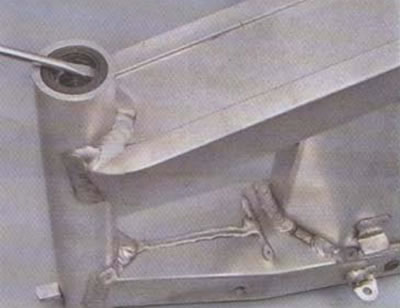

6. Having rested the drift against the remote bushing of the pendulum, we press out the bearings one by one with light blows of a hammer, avoiding distortions of the bearings.

Bearings should rotate smoothly, without extraneous noise and jamming. Otherwise, we replace them.

Installation

Before installing new bearings, apply a small amount of grease to them. Pressing the bearings into the pendulum is recommended to be done by preheating the mounting holes with an industrial hair dryer. For pressing it is convenient to use a special mandrel or tool head of a suitable size.

Attention! When pressing out, the gland is inevitably deformed. When assembling, a new set of oil seals must be installed. The seals are installed with the open side inward.

The final assembly is carried out in the reverse order.