Warning! Gasoline is extremely flammable and can be explosive under certain conditions. Turn the ignition switch OFF. Do not smoke. Make sure the area is well-ventilated and free from any source of flame or sparks; this includes any appliance with a pilot light.

Remove the carburetors.

Before disassembling the carburetors, check the fuel level (see Fuel Level Inspection).

★ If the fuel level is incorrect, inspect the rest of the carburetor before correcting it.

Slide the starter plunger lever to the left and release it to check that the starter plungers move smoothly and return by spring tension.

★ If the starter plungers do not work properly, replace the carburetors.

Turn the throttle cable pulley to check that the throttle butterfly valves [A] move smoothly and return by spring tension.

★ If the throttle valves do not move smoothly, replace the carburetors.

Disassemble the carburetors.

Clean the carburetors.

Check that the О-rings on the float bowl and pilot screw and the diaphragm on the vacuum piston are in good condition.

If any of the О-rings or diaphragms are not in good condition, replace them.

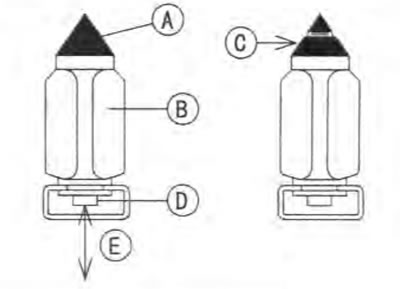

Check the plastic tip [A] of the float valve needle [В]. It should be smooth, without any grooves, scratches, or tears.

★ If the plastic tip is damaged [C], replace the needle.

Push the rod [D] in the other end of the float valve needle, and then release it [Е].

★ If the rod does not spring out, replace the needle.

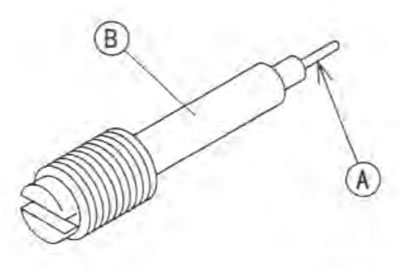

Check the tapered portion [A] of the pilot screw [B] for wear or damage.

★ If the pilot screw is worn or damaged on the tapered portion, it will prevent the engine from idling smoothly. Replace it.

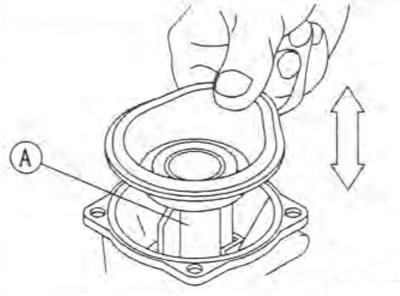

Check that the vacuum piston [A] moves smoothly in the carburetor body. The surface of the piston must not be excessively worn.

★ If the vacuum piston does not move smoothly or if it is very loose in carburetor body, replace the carburetor.