Note. Carry out maintenance operations at half the intervals shown if the vehicle is used in wet or dusty areas, off road or for sporting applications.

Clearance check

To check clearance:

- Shut off the engine.

- Rest the vehicle on its stand.

- Engage neutral gear.

- Check that the vertical oscillation at a point between the pinion and the sprocket on the lower branch of the chain is around 25 mm (0,98 in).

- Move the vehicle forward so as to check vertical oscillation of the chain in other positions too. clearance should remain constant at all wheel rotation phases.

Adjustment

Caution! Get a specific rear service stand (opt) to adjust the chain.

If you need to adjust chain tension after the check:

- Place the vehicle on its rear service stand (OPT).

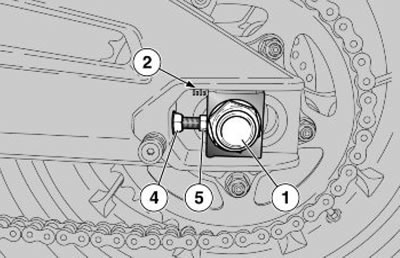

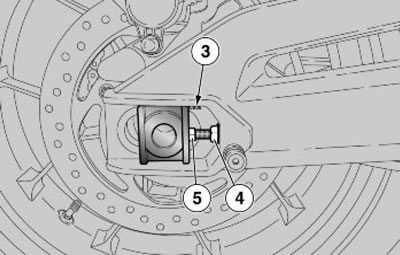

- Loosen the nut (1) completely.

- Loosen both lock nuts (4).

- Actuate on the adjuster screws (5) and adjust the chain clearance checking that the references (2-3) match on both sides of the vehicle.

- Tighten both lock nuts (4).

- Tighten the nut (1).

- Check chain clearance.

Caution! To ensure that the wheel is correctly centred, there are fixed reference markings (2-3) inside the chain tensioner slider seats on the swingarms, in front of the wheel axle.

Checking the chain, the pinion and the sprocket for wear

Furthermore, check the following parts and make sure the chain, the pinion and the sprocket do not show:

- damaged rollers;

- loosened pins;

- dry, rusty, flattened or jammed chain links;

- excessive wear;

- missing sealing rings;

- excessively worn or damaged pinion or sprocket teeth.

Caution!

- If the chain rollers are damaged, the pins are loose and/or the seal rings are missing or damaged, the whole chain unit (pinion, sprocket and chain) should be replaced.

- Lubricate the chain on a regular basis, particularly if you detect dry or rusty parts.

- Flattened or jammed chain links should be lubricated and good operating conditions restored.

Caution!

- The gearing chain has sealing rings among the links that keep the grease inside.

- Adjust, lubricate, wash and replace the chain with utmost caution.

Cleaning and lubrication

Do not wash the chain with water jets, steam jets, high-pressure water jets and highly flammable solvents.

Wash the chain with fuel oil or kerosene. Maintenance operations should be more frequent if there are signs of quick rust.

Lubricate the chain at the intervals specified on the routine maintenance table and whenever necessary.

Wash the chain, allow to dry and lubricate with spray grease for sealed chains.

See also specifications for this operation.