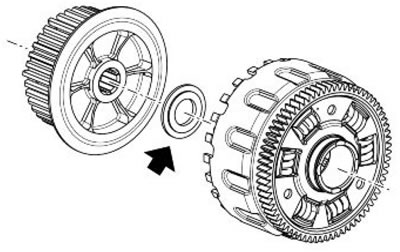

Fit the needle bearing and the spacer.

Fit the clutch bell.

Make sure that the oil pump control drive gear of the clutch bell engages correctly with the oil pump driven gear.

Place the special washer correctly between the clutch bell and the hub.

Caution! Fit the special washer with the machining facing the bell.

Position the clutch hub.

Fit the clutch cover.

Check that the measurement has not changed compared with the one carried out upon removal; tighten the clutch nut afterwards. If it has changed, rotate the crankshaft so that the oil pump control drive gear engages correctly with the oil pump driven gear on the clutch bell.

Fit the washer and a new clutch hub nut.

Tighten the clutch hub nut using the specific tool.

Specific tooling: 9100896 Clutch bell locking tool

Tighten the nut and proceed to caulk.

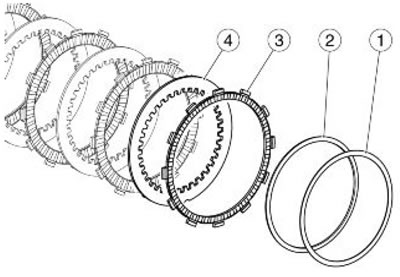

- Insert the flat ring (1).

- Insert the cupped ring (2).

- Fit the lathed driven disc (3).

- Fit the nitrided steel disc (4).

Caution! Be careful with the cupped ring fitting side; the ring cone shall be directed towards the engine.

Fit the clutch discs. Start with the friction material discs and alternate with steel discs.

Position all friction material discs with their teeth aligned in one of the long slots of the clutch bell.

Place the control rod.

Place the thrust plate.

Caution! Ensure that the arrow on the thrust plate is aligned with the machining on the hub.

Fit the clutch springs.

Fit the screw washers.

Tighten the six screws operating in stages and diagonally.

Replace the gasket upon refitting.

See also specifications for this operation.