General

Some electrical components may be damaged if terminals or connectors are connected or disconnected while the ignition switch is turned to "ON" and current is present.

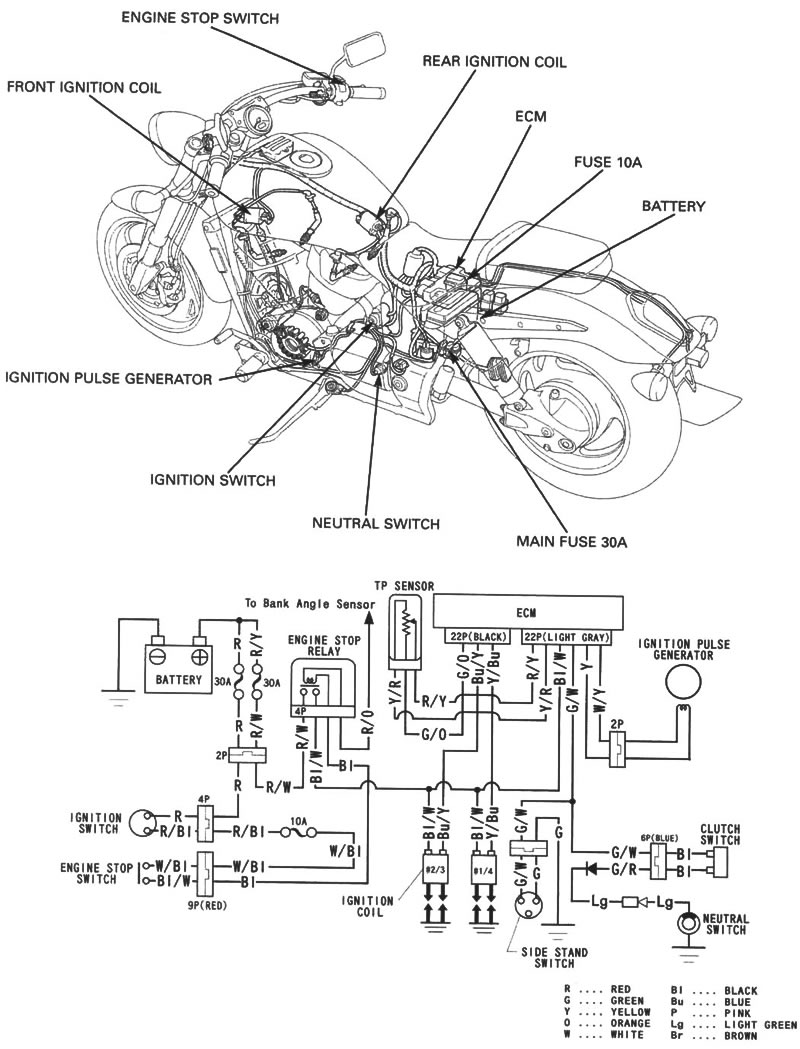

When servicing the ignition system, always follow the steps in the troubleshooting sequence on page 17-2.

The ignition timing cannot be adjusted since the Engine Control Module (ECM) is factory preset.

The ECM may be damaged if dropped. Also, if the connector is disconnected when current is flowing, the excessive voltage may damage the ECM. Always turn the ignition switch to "OFF" before servicing.

A faulty ignition system is often related to poor connected or corroded connectors. Check those connections before proceeding.

Some electrical components may be damaged if terminals or connectors are connected or disconnected while the ignition switch is turned to "ON" and current is present.

Use a spark plug of the correct heat range. Using a spark plug with an incorrect heat range can damage the engine.

For ignition switch and engine stop switch inspection, refer to Section 19.

For side stand and neutral switch inspection, see Section 19.

For ECM removal/installation, see page 5-73.

Specification

| ITEM | SPECIFICATIONS | ||

| Spark plug | Standard | IFR6L11 (NGK) | VK20PRZ11 (DENSO) |

| For cold climate/below 5°C/41°F | IFR5L11 (NGK) | VK16PRZ11 (DENSO) | |

| For extended high speed riding | IFR7L11 (NGK) | VK22PRZ11 (DENSO) | |

| Spark plug gap | 1.0 - 1.1 mm (0.039 - 0.043 in) | ||

| Ignition coil peak voltage | 100 V minimum | ||

| Ignition pulse generator peak voltage | 0.7 V minimum | ||

| Ignition timing ("F" mark) | 8° BTDC at idle | ||

Torque values

| Crankshaft hole cap | 18 N*m (1.8 kgf·m, 13 lbf·ft) | Apply grease to the threads. |