Honda:

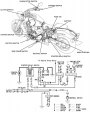

Engine start and battery charging system of motorcycle Honda VTX1800C (VTX series, 2001-2008)

See this section in russian language

Service information of charging system and alternator

General Caution! The battery gives off explosive gases; keep sparks, flames and cigarettes away. Provide adequate ventilation when charging. The battery contains sulfuric acid (electrolyte). Contact with skin or eyes may cause severe burns. Wear...

General Caution! The battery gives off explosive gases; keep sparks, flames and cigarettes away. Provide adequate ventilation when charging. The battery contains sulfuric acid (electrolyte). Contact with skin or eyes may cause severe burns. Wear...

Troubleshooting of charging system and alternator

Battery is damaged or weak Remove the battery ( page 16-4 ). Check the battery condition using the recommended battery tester. Recommended battery tester: BM-210-AH or BM-210 (U.S.A, only) Incorrect → Faulty battery. ↓ Correct ↓ Install the battery...

Battery is damaged or weak Remove the battery ( page 16-4 ). Check the battery condition using the recommended battery tester. Recommended battery tester: BM-210-AH or BM-210 (U.S.A, only) Incorrect → Faulty battery. ↓ Correct ↓ Install the battery...

Battery — removal and installation

Removal Remove the seat ( page 2-2 ). Remove the ECM ( page 5-73 ). Remove the screws and battery case cover. With the ignition switch turned to "OFF", remove the terminal screw and disconnect the negative (-) cable first, then remove the terminal...

Removal Remove the seat ( page 2-2 ). Remove the ECM ( page 5-73 ). Remove the screws and battery case cover. With the ignition switch turned to "OFF", remove the terminal screw and disconnect the negative (-) cable first, then remove the terminal...

Battery — inspection and testing

Voltage inspection Remove the seat ( page 2-2 ). Remove the ECM ( page 5-73 ). Measure the battery voltage using a commercially available digital multimeter. Voltage (20°C/68°F): Fully charged: 13.0-13.2 V Under charged:Below 12.3 V Tool: Digital...

Voltage inspection Remove the seat ( page 2-2 ). Remove the ECM ( page 5-73 ). Measure the battery voltage using a commercially available digital multimeter. Voltage (20°C/68°F): Fully charged: 13.0-13.2 V Under charged:Below 12.3 V Tool: Digital...

Battery — charging

Remove the battery ( page 16-4 ). Clean the battery terminals and position the battery as far away from the charger as the leads will permit. Do not place batteries below the charger - gases from the battery may corrode and damage the charger. Do...

Remove the battery ( page 16-4 ). Clean the battery terminals and position the battery as far away from the charger as the leads will permit. Do not place batteries below the charger - gases from the battery may corrode and damage the charger. Do...

Charging system inspection

Remove the seat ( page 2-2 ). Remove the ECM ( page 5-73 ). Current leakage test Turn the ignition switch to "OFF", and disconnect the negative (-) cable from the battery. Connect the ammeter (+) probe to the negative (-) cable and ammeter (-) probe...

Remove the seat ( page 2-2 ). Remove the ECM ( page 5-73 ). Current leakage test Turn the ignition switch to "OFF", and disconnect the negative (-) cable from the battery. Connect the ammeter (+) probe to the negative (-) cable and ammeter (-) probe...

Battery case — removal and installation

Remove the battery ( page 16-4 ). Disconnect the BARO sensor 3P connector ( page 5-67 ). Disconnect the bank angle sensor 3P green connector ( page 5-71 ). Remove the screws and tool box cover. Remove the bolts and battery case.

Remove the battery ( page 16-4 ). Disconnect the BARO sensor 3P connector ( page 5-67 ). Disconnect the bank angle sensor 3P green connector ( page 5-71 ). Remove the screws and tool box cover. Remove the bolts and battery case.

Regulator/rectifier — removal and installation

Wire harness inspection Remove the seat ( page 2-2 ). Remove the left crankcase rear cover ( page 2-2 ). Disconnect the regulator/rectifier 6P and alternator 3P connectors. Check the connectors for loose or corroded terminals. Battery line Measure...

Wire harness inspection Remove the seat ( page 2-2 ). Remove the left crankcase rear cover ( page 2-2 ). Disconnect the regulator/rectifier 6P and alternator 3P connectors. Check the connectors for loose or corroded terminals. Battery line Measure...

Alternator — inspection

Remove the left crankcase rear cover ( page 2-2 ). Disconnect the alternator 3P connector. Measure the resistance between Yellow wire terminals of the wire harness side. Standard: 0.1-1.0 Ω (20°C/68°F). Check for continuity between each Yellow wire...

Remove the left crankcase rear cover ( page 2-2 ). Disconnect the alternator 3P connector. Measure the resistance between Yellow wire terminals of the wire harness side. Standard: 0.1-1.0 Ω (20°C/68°F). Check for continuity between each Yellow wire...

Alternator — left crankcase cover removal

Remove the left crankcase rear cover ( page 2-2 ). Remove the slave cylinder ( page 10-11 ). Disconnect the alternator 3P and 2P connectors. Remove the pinch bolt and the gearshift arm from the gearshift spindle. Disconnect the horn connectors (...

Remove the left crankcase rear cover ( page 2-2 ). Remove the slave cylinder ( page 10-11 ). Disconnect the alternator 3P and 2P connectors. Remove the pinch bolt and the gearshift arm from the gearshift spindle. Disconnect the horn connectors (...

Alternator — stator removal and installation

Removal Remove the clamp bolts and clamp. Remove the stator bolts and wire grommets, then remove the stator and ignition pulse generator from the left crankcase cover. Installation Clean the mating surfaces of the left crankcase cover and left...

Removal Remove the clamp bolts and clamp. Remove the stator bolts and wire grommets, then remove the stator and ignition pulse generator from the left crankcase cover. Installation Clean the mating surfaces of the left crankcase cover and left...

Alternator — left crankcase cover installation

Clean the mating surfaces of the right crankcase cover and right crankcase. Be careful not to damage the right crankcase and cover mating surfaces. Apply sealant to the right crankcase cover mating surface. Install the dowel pins to the left...

Clean the mating surfaces of the right crankcase cover and right crankcase. Be careful not to damage the right crankcase and cover mating surfaces. Apply sealant to the right crankcase cover mating surface. Install the dowel pins to the left...

Service information of electric starter

General Always turn the ignition switch to "OFF" before servicing the starter motor. The motor could suddenly start, causing serious injury. The starter motor can be serviced with the engine in the frame. When checking the starter system, always...

General Always turn the ignition switch to "OFF" before servicing the starter motor. The motor could suddenly start, causing serious injury. The starter motor can be serviced with the engine in the frame. When checking the starter system, always...

Troubleshooting of electric starter

Check for the following before troubleshooting: Blown main fuse (30 A) and sub fuse (10 A) Loose battery and starter motor cable Discharged battery With the ignition switch turned to "ON" and the engine stop switch to "", the starter motor can be...

Check for the following before troubleshooting: Blown main fuse (30 A) and sub fuse (10 A) Loose battery and starter motor cable Discharged battery With the ignition switch turned to "ON" and the engine stop switch to "", the starter motor can be...

Starter motor — removal

Remove the starter drive gear ( page 18-12 ). With the ignition switch turned to "OFF", remove the negative cable at the battery before servicing the starter motor. Release the rubber cap and remove the terminal nut to disconnect the starter motor...

Remove the starter drive gear ( page 18-12 ). With the ignition switch turned to "OFF", remove the negative cable at the battery before servicing the starter motor. Release the rubber cap and remove the terminal nut to disconnect the starter motor...

Starter motor — disassembly

Remove the starter motor case bolts and rear cover. Record the location and number of shims. Remove the following: Shims Seal ring Front cover Seal ring Lock washer Insulated washer Shims Armature

Remove the starter motor case bolts and rear cover. Record the location and number of shims. Remove the following: Shims Seal ring Front cover Seal ring Lock washer Insulated washer Shims Armature

Starter motor — inspection

Check for continuity between the cable terminal and the (+) brushes. There should be continuity. Check for continuity between the motor case and the cable terminal. There should be no continuity. Check for continuity between the (+) and (-)...

Check for continuity between the cable terminal and the (+) brushes. There should be continuity. Check for continuity between the motor case and the cable terminal. There should be no continuity. Check for continuity between the (+) and (-)...

Starter motor — assembly

Set the collar on the brush/terminal. Set the brush/terminal on the brush holder. Install the brush holder onto the motor case. Align the terminal holder boss with the groove in the motor case. Install the following: O-ring Insulators Washer Nut...

Set the collar on the brush/terminal. Set the brush/terminal on the brush holder. Install the brush holder onto the motor case. Align the terminal holder boss with the groove in the motor case. Install the following: O-ring Insulators Washer Nut...

Starter motor — installation

Apply clean engine oil to the new O-ring. Install the О-ring to the groove on the starter motor. Install the starter motor into the crankcase. Install and tighten the bolts securely. Route the starter motor cable and tighten the terminal nut to the...

Apply clean engine oil to the new O-ring. Install the О-ring to the groove on the starter motor. Install the starter motor into the crankcase. Install and tighten the bolts securely. Route the starter motor cable and tighten the terminal nut to the...

Starter relay switch — inspection

Remove the left side cover ( page 2-2 ). Shift the transmission into neutral. Turn the ignition switch to "ON" and engine stop switch to "". Depress the starter switch button. The coil is normal if the starter relay switch clicks. If you do not hear...

Remove the left side cover ( page 2-2 ). Shift the transmission into neutral. Turn the ignition switch to "ON" and engine stop switch to "". Depress the starter switch button. The coil is normal if the starter relay switch clicks. If you do not hear...

Starter relay switch — removal and installation

Remove the left side cover ( page 2-2 ). Disconnect the starter relay switch connectors. Remove the nuts and cables. Remove the starter relay switch from the tabs on the battery case. Installation is in the reverse order of removal.

Remove the left side cover ( page 2-2 ). Disconnect the starter relay switch connectors. Remove the nuts and cables. Remove the starter relay switch from the tabs on the battery case. Installation is in the reverse order of removal.

Starter driven gear/torque limiter removal

Remove the left crankcase cover ( page 16-9 ). Remove the shaft, starter drive gear and torque limiter.

Remove the left crankcase cover ( page 16-9 ). Remove the shaft, starter drive gear and torque limiter.

Left crankcase cover bearing replacement

Check the left crankcase cover bearing for damage or excessive play. Replace, if necessary. Heat the left crankcase cover to 80°C (176°F) evenly using a heat gun. Remove the bearing with the following special tools. Always wear insulated gloves when...

Check the left crankcase cover bearing for damage or excessive play. Replace, if necessary. Heat the left crankcase cover to 80°C (176°F) evenly using a heat gun. Remove the bearing with the following special tools. Always wear insulated gloves when...

Left crankcase bearing replacement

Check the left crankcase bearing for damage or excessive play. Replace, if necessary. Heat the left crankcase cover to 80°C (176°F) evenly using a heat gun. Remove the bearing with the following special tools. Always wear insulated gloves when...

Check the left crankcase bearing for damage or excessive play. Replace, if necessary. Heat the left crankcase cover to 80°C (176°F) evenly using a heat gun. Remove the bearing with the following special tools. Always wear insulated gloves when...

Starter drive gear inspection

Check the starter drive gear for abnormal wear or damage. Check the starter drive gear shaft for abnormal wear or damage.

Check the starter drive gear for abnormal wear or damage. Check the starter drive gear shaft for abnormal wear or damage.

Starter torque limiter inspection

Check the starter torque limiter gear for abnormal wear or damage. Hold the torque limiter in a vise with soft jaws or a shop towel to prevent damaging the gear teeth. Check the torque limiter slip torque with the special tool and a torque wrench....

Check the starter torque limiter gear for abnormal wear or damage. Hold the torque limiter in a vise with soft jaws or a shop towel to prevent damaging the gear teeth. Check the torque limiter slip torque with the special tool and a torque wrench....

Flywheel — removal

Remove the left crankcase cover ( page 16-9 ). Hold the flywheel using the flywheel holder, then remove the flywheel bolt. Tool: Flywheel holder 07725-0040000. Remove the washer. Remove the flywheel using the special tool. Tool: Flywheel puller...

Remove the left crankcase cover ( page 16-9 ). Hold the flywheel using the flywheel holder, then remove the flywheel bolt. Tool: Flywheel holder 07725-0040000. Remove the washer. Remove the flywheel using the special tool. Tool: Flywheel puller...

Starter clutch — removal

Remove the flywheel ( page 18-14 ). Hold the flywheel with the special tool and remove the starter clutch outer bolts. Do not remove the clutch housing and one-way clutch unless it is necessary to inspect them. Tool: Flywheel holder 07725-0040000....

Remove the flywheel ( page 18-14 ). Hold the flywheel with the special tool and remove the starter clutch outer bolts. Do not remove the clutch housing and one-way clutch unless it is necessary to inspect them. Tool: Flywheel holder 07725-0040000....

Starter clutch — inspection

Check the sprag clutch and clutch outer for abnormal wear or damage. Check the needle bearing for abnormal wear or damage. Check the starter driven gear for abnormal wear or damage. Measure the starter driven gear O.D. Service limit: 57.639 mm...

Check the sprag clutch and clutch outer for abnormal wear or damage. Check the needle bearing for abnormal wear or damage. Check the starter driven gear for abnormal wear or damage. Measure the starter driven gear O.D. Service limit: 57.639 mm...

Starter clutch — installation

Apply engine oil to the sprag clutch outer surfaces. Install the sprag clutch into the starter clutch outer as shown. If the spring was off the clutch groove, replace the one-way clutch (clutch and spring) as an assembly. Install the starter clutch...

Apply engine oil to the sprag clutch outer surfaces. Install the sprag clutch into the starter clutch outer as shown. If the spring was off the clutch groove, replace the one-way clutch (clutch and spring) as an assembly. Install the starter clutch...

Flywheel — installation

Clean any oil from the tapered portion of the crankshaft and flywheel. Install the woodruff key in the crankshaft key groove. Clean any oil from the tapered portion of the flywheel I.D. Install the flywheel on the crankshaft, aligning the keyway...

Clean any oil from the tapered portion of the crankshaft and flywheel. Install the woodruff key in the crankshaft key groove. Clean any oil from the tapered portion of the flywheel I.D. Install the flywheel on the crankshaft, aligning the keyway...

Starter driven gear/torque limiter installation

Install the torque limiter, shaft and starter driven gear. Install the left crankcase cover ( page 16-11 ).

Install the torque limiter, shaft and starter driven gear. Install the left crankcase cover ( page 16-11 ).

Balancer weight — removal and installation

Removal Remove the left crankcase cover ( page 16-11 ). Remove the right crankcase cover ( page 10-13 ). Insert the gear holder between the primary driven gear and primary drive gear. Tool: Gear holder 07724-0010100 not available in USA. Loosen the...

Removal Remove the left crankcase cover ( page 16-11 ). Remove the right crankcase cover ( page 10-13 ). Insert the gear holder between the primary driven gear and primary drive gear. Tool: Gear holder 07724-0010100 not available in USA. Loosen the...

Similar subsections of other motorcycle models

Starting and charging system motorcycle Aprilia RS-series RS 125 (1999-2005, 3 generation)

Starting and charging system motorcycle BMW K-series K 1200 LT (1997-2008)

Starting and charging system motorcycle Ducati Monster 696 (2007-2014)

Starting and charging system motorcycle Harley Street 750/500 (2014-2021)

Starting and charging system motorcycle Kawasaki Versys 650 (2007-2025)

Starting and charging system motorcycle Suzuki Boulevard M109R (2006-2025)

Starting and charging system motorcycle Triumph Tiger 800 (2010-2019)

Starting and charging system motorcycle Yamaha YZF-R1 Y(C) (2009-2011, 8 generation)

- Information for owner

- Control devices

- Operation manual

- Maintenance

- Engine and systems

- Engine repair

- Fuel and control system

- Cooling system

- Lube system

- Transmission

- Running gear and frame

- Frame and hinged elements

- Front suspension and handlebar

- Rear suspension

- Brake system

- Electric equipment

- Equipment and devices

- Ignition system

- Starting and charging system

Aprilia: RS-series Shiver (map) BMW: F-series R-series K-series (map) Ducati: ST series Monster (map) Harley: Street Sportster V-Rod (map) Honda: Africa Twin CB series VTX series (map) Kawasaki: ZX-6R Versys Vulcan (map) Suzuki: DR-Z V-Strom Boulevard (map) Triumph: Rocket Street Triple Tiger (map) Yamaha: Fazer DragStar R1 (map)