General

Be sure to relieve the fuel pressure with the ignition switch turned to "OFF".

Bending or twisting the control cables will impair smooth operation and could cause the cables to stick or bind, resulting in loss of vehicle control.

Work in a well ventilated area. Smoking or allowing flames or sparks in the work area or where gasoline is stored can cause a fire or explosion.

Do not apply commercially available carburetor cleaners to the inside of the throttle bore, which is coated with molybdenum.

Seal the cylinder head intake ports with tape or a clean cloth to keep dirt and debris from entering the intake ports after incorrect idle operation.

Do not apply excessive force to the fuel pipe on the throttle body while removing or installing the throttle body.

Do not damage the throttle body. It may cause incorrect air screw synchronization.

Prevent dirt and debris from entering the throttle bore, fuel hose and return hose, clean them using compressed air.

The throttle body is factory pre-set. Do not disassemble in a way other than shown in this manual.

Do not loosen or tighten the white painted bolts and screws of the throttle body. Loosening or tightening them can cause throttle valve synchronization failure.

Do not push the fuel pump base under the fuel tank when the fuel tank is stored.

Always replace the packing when the fuel pump is removed.

The programmed fuel injection system is equipped with the Self-Diagnostic System described on page 5-5. If the MIL blinks, follow the Self-Diagnostic Procedures to remedy the problem.

When checking the PGM-FI, always follow the steps in the troubleshooting flow chart (page 5-10).

The PGM-FI system is provided with a failsafe function to secure a minimum running capability even when there is no trouble in the system. When any abnormality is detected by the self-diagnosis function, running capability is secured by making use of the numerical values of a situation preset in advance in the simulated program map. It must be remembered, however, that when any abnormality is detected in four injectors and/or the ignition and cam pulse generator, the fail safe function stops the engine from the standpoint of protecting it.

For PGM-FI system component location, see page 5-4.

A faulty PGM-FI system is often related to poorly connected or corroded connectors. Check those connections before proceeding.

The vehicle speed sensor sends digital pulse signal to the ECM (PGM-FI unit) and computation. For vehicle speed sensor inspection, see section 19.

When disassembling the programmed fuel injection parts, note the location of the О-rings. Replace them with new ones upon reassembly.

Before disconnecting the fuel hose, release the fuel pressure by loosing the fuel hose banjo bolt at the fuel tank.

Always replace the sealing washers when the fuel hose banjo bolt is removed or loosened.

Use a digital tester for PGM-FI system inspection.

Specifications

| ITEM | SPECIFICATIONS |

| Throttle body identification number | GQ42A |

| Idle speed | 800±100 rpm |

| Throttle grip free play | 2 - 6 mm (1/16-1/4 in) |

| Intake air temperature sensor resistance (at 20°C/68T) | 1 - 4 kΩ |

| Engine coolant temperature sensor resistance (at 20°C/68°F) | 2.3-2.6 kΩ |

| Fuel injector resistance (at 20°C/68°F) | 13.4-14.2 Ω |

| PAIR solenoid valve resistance (at 20°C/68°F) | 20-24 Ω |

| Cam pulse generator peak voltage (at 20°C/68°F) | 0.7 V minimum |

| Ignition pulse generator peak voltage (at 20°C/68°F) | 0.7 V minimum |

| Manifold absolute pressure at idle | 290 mm Hg |

| Fuel pressure at idle | 343 kPa (3.5 kgf/cm2, 50 psi) |

| Fuel pump flow (at 12 V) | 188 cm3 (6.4 US oz, 6.6 Imp oz) minimum/10 seconds |

Torque values

| Air cleaner housing cover bolt | 3.4 N·m (0.35 kgf·m, 2.5 lbf·ft) |

| Fuel tank rear mounting bolt | 12 N·m (1.2 kgf·m, 9 lbf·ft) |

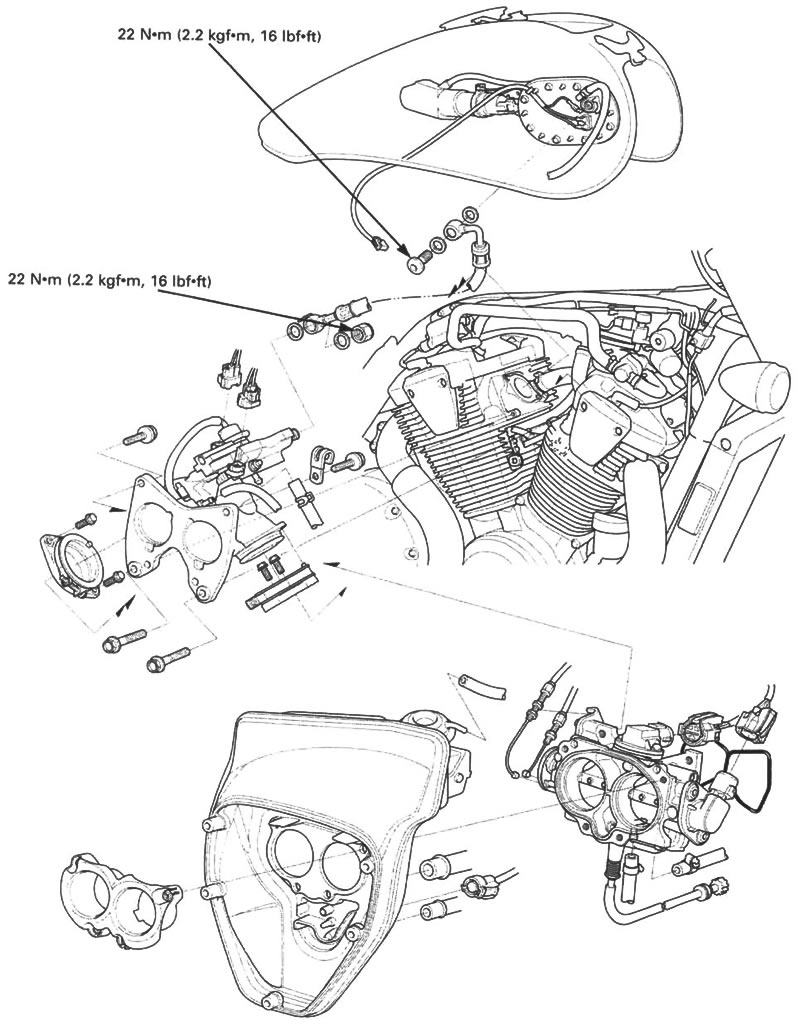

| Fuel hose banjo bolt (fuel tank side) | 22 N·m (2.2 kgf·m, 16 lbf·ft) |

| Fuel hose sealing nut (throttle body side) | 22 N·m (2.2 kgf·m, 16 lbf·ft) |

| Fuel pump mounting nut | 12 N·m (1.2 kgf·m, 9 lbf·ft) |

| Starter valve screw | 3.4 N·m (0.35 kgf·m, 2.5 lbf·ft) |

| MAP sensor screw | 2.1 N·m (0.21 kgf·m, 1.5 lbf·ft) |

| Throttle cable guide screw | 3.4 N·m (0.35 kgf·m, 2.5 lbf·ft) |

| ECT sensor | 18 N·m (1.8 kgf·m, 13 lbf·ft) |

| O2 sensor | 25 N·m (2.6 kgf·m, 19 lbf·ft) |

Tools

| Fuel pressure gauge | 07406-004000A |

| Pilot screw wrench | 07908-4730002 |

| Peak voltage tester or Peak voltage adaptor | 07HGJ-0020100 (not available in U.S.A.) with commercially available digital multi-meter (impedance 10MΩ/DCV minimum) |

| Vacuum gauge set | 07LMJ-001000A |

| ECU test harness | 07YMZ-0010100 (two required) |