Source of emissions

The combustion process produces carbon monoxide, oxides of nitrogen and hydrocarbons. Control of oxides of nitrogen and hydrocarbons is very important because, under certain conditions, they react to form photochemical smog when subjected to sunlight. Carbon monoxide does not react in the same way, but it is toxic.

Honda Motor Co., Ltd. utilizes lean injection settings as well as other systems, to reduce carbon monoxide and hydrocarbons.

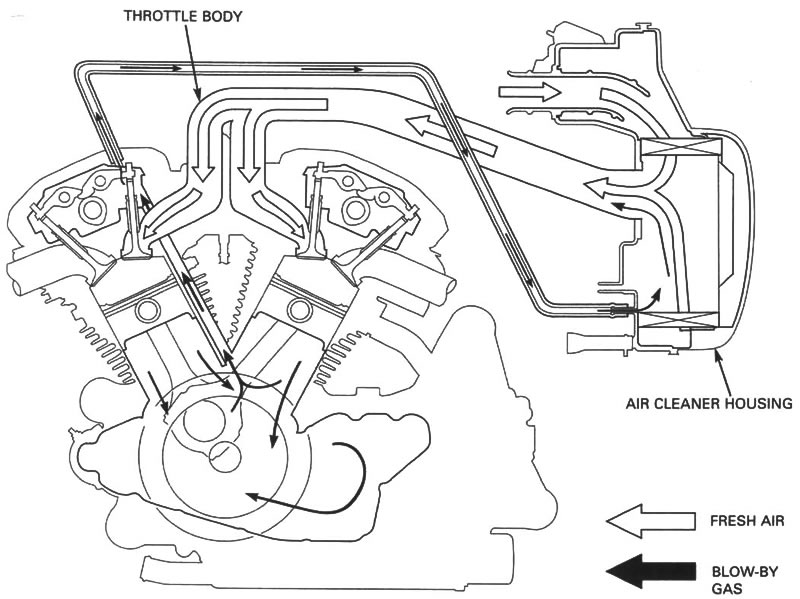

Crankcase emission control system

The engine is equipped with a closed crankcase system to prevent discharging crankcase emissions into the atmosphere. Blow-by gas is returned to the combustion chamber through the air cleaner and throttle body.

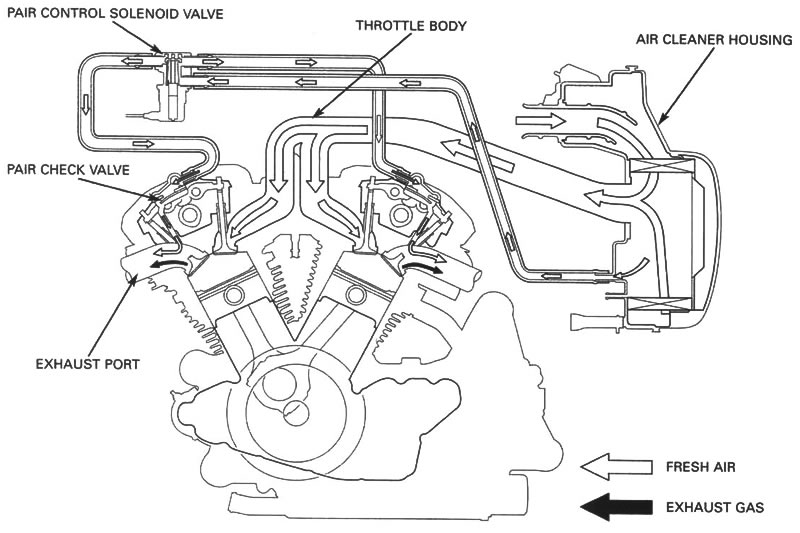

Exhaust emission control system (secondary air supply system)

The exhaust emission control system is composed of a lean fuel injection setting, and no adjustments should be made except idle speed adjustment with the throttle stop screw. The exhaust emission control system is separate from the crankcase emission control system.

The exhaust emission control system consists of a secondary air supply system which introduces filtered air into the exhaust gases in the exhaust port. Fresh air is drawn into the exhaust port by the function of the PAIR (Pulse Secondary Air Injection) control valve.

This charge of fresh air promotes burning of the unburned exhaust gases and changes a considerable amount of hydrocarbons and carbon monoxide into relatively harmless carbon dioxide and water vapor.

The reed valve prevents reverse air flow through the system. The PAIR control valve is operated by the solenoid valve. The solenoid valve is controlled by the PGM-FI unit, and the fresh air passage is opened/closed according the running condition (ECT/IAT/TP/MAP sensor and engine revolution).

No adjustments to the secondary air supply system should be made, although periodic inspection of the components is recommended.

California type: The California type is also equipped with a three-way catalytic converter, and a heated oxygen sensor. The three-way catalytic converters are in the exhaust system. Through chemical reactions, they convert HC, CO, and NOx in the engine's exhaust to carbon dioxide (CO2), dinitrogen (Na), and water vapor. No adjustment to these systems should be made although periodic inspection of the components is recommended.

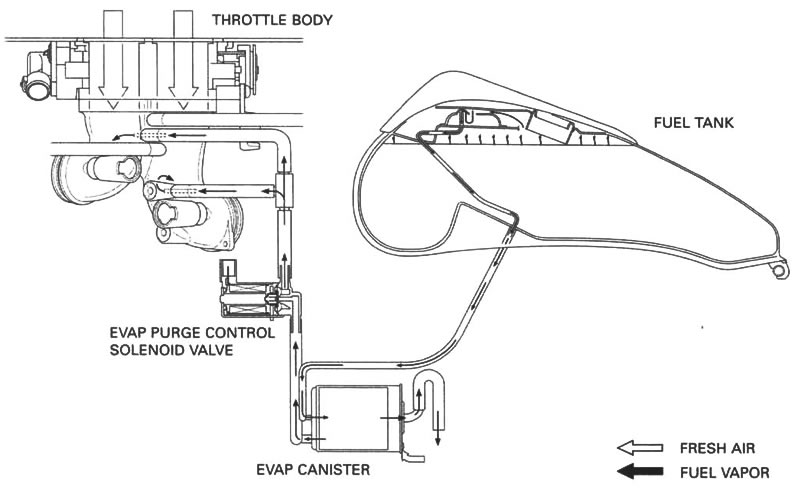

Evaporative emission control system (California type only)

This model complies with California Air Resources Board evaporative emission requirements.

Fuel vapor from the fuel tank is routed into the evaporative emission (EVAP) canister where it is absorbed and stored while the engine is stopped. When the engine is running and the evaporative emission (EVAP) purge control solenoid valve is open, fuel vapor in the EVAP canister is drawn into the engine through the throttle body.

Noise emission control system

Tampering with the noise control system is prohibited: U.S. Federal low prohibits, or Canadian provincial law may prohibit the following acts or the causing there of: (1) The removal or rending inoperative by any person, other than for the purposes of maintenance, repair or replacement, of any device or element of design incorporated into any vehicle for the purpose of noise control prior to its sale or delivery to the ultimate customer or while it is in use; or (2) the use of any vehicle after such device or element of design has been remove or rendered inoperative by any person.

Among those acts presumed to constitute tampering are the acts listed below:

- 1. Removal of, or puncturing of the muffler, baffles, header pipes or any other component which conducts exhaust gases. 2. Removal of, or puncturing of any part of the intake system.

- 3. Lack of proper maintenance.

- 4. Replacing any moving parts of the vehicle, or parts of the exhaust or intake system, with parts other then those specified by the manufacturer.