Removal

- Split the crankcase (see Crankcase Splitting).

- Remove the connecting rod nuts.

- Remove the crankshaft.

Note. Mark and record the locations of the connecting rods and their big end caps so that they can be reassembled in their original positions.

Remove the connecting rods from the crankshaft.

Installation

Caution! To minimize vibration, the connecting rods should have the same weight mark.

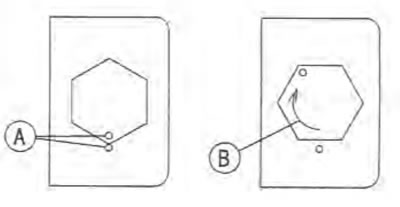

- Big End Cap [A]

- Connecting Rod [B]

- Weight Mark, Alphabet [C]

- Diameter Mark [D]

If the connecting rods, big end bearing inserts, or crankshaft are replaced with new ones, select the bearing insert and check clearance with a plastigage (press gauge) before assembling engine to be sure the correct bearing inserts are installed.

Caution! The connecting rod bolts are designed to stretch when tightened. Never reuse them.

Replace the connecting rod big end bolts and nuts with new ones.

Be sure to clean the bolts, nuts, and connecting rods thoroughly with high-flash point solvent, because the new connecting rods, bolts, and nuts are treated with an anti-rust solution.

Warning! Clean he bolts, nuts, and connecting rods in a well-ventilated area, and take care that there is no spark or flame anywhere near the working area. This includes any appliance with a pilot light. Because of the danger of highly flammable liquids, do not use gasoline or low-flash point solvents to clean them.

Caution!

- Immediately dry the bolts and nuts with compressed air after cleaning.

- Clean and dry the bolts and nuts completely.

Apply engine oil to the inner surface of upper and lower bearing inserts [А].

Apply a small amount of engine oil to the threads [B] and seating surface [C] of the connecting rod nuts.

First, tighten the nuts to the specified torque.

Next, tighten the nuts 160° more.

Mark [A] the connecting rod big end caps and nuts so that nuts can be turned 160 [B] properly.

Torque + Angle - 15 N·m (1.5 kg·m, 11 ft·lb) + 160°

Caution! Since the friction force of the eating surface and thread portion of new nuts is different from that of used ones, the nut tightening torque should be changed as specified in the above table.

Be careful not to overtighten the nuts.

Cleaning

After removing the connecting rods from the crankshaft, clean them with a high-flash point solvent.

Blow the crankshaft oil passages with compressed air to remove any foreign particles or residue that may have accumulated in the passages.