1. Remove and discard the seal.

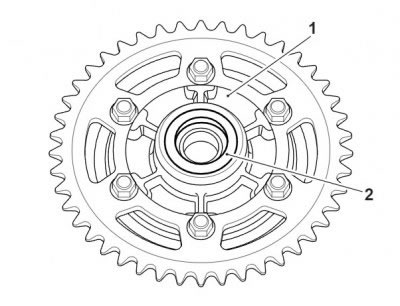

1. Sprocket carrier; 2. Seal

2. Remove and discard the bearing circlip.

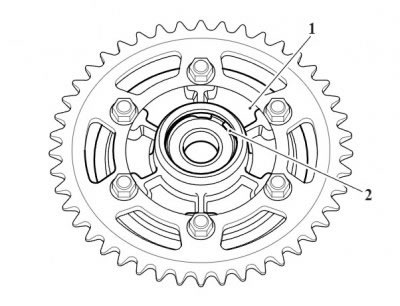

1. Sprocket carrier; 2. Circlip

Warning! Always wear eye, hand and face protection when using a hammer and drift. Use of a hammer and drift can cause bearings to fragment. Pieces of fragmented bearing could cause eye and soft tissue injuries if suitable protective apparel is not worn.

Caution! To prevent sprocket carrier damage and to aid bearing removal, always apply force evenly on both sides of the bearing to prevent it from 'tipping' and becoming stuck. Application of uneven force will lead to difficulty in removing the bearing and to a damaged drive flange.

3. Turn the sprocket carrier over, and use a pin punch to drift out the ball bearing.

1. Sprocket carrier; 2. Ball bearing

Rear sprocket carrier and cush drive - inspection

1. Check the cush drive rubbers for deterioration and cracks.

2. Inspect the sprocket teeth for wear, damage and chips.

3. Check the wheel and drive flange for wear, cracks and damage.