Inspection

Clean all intake and exhaust valves thoroughly to remove the carbon deposits.

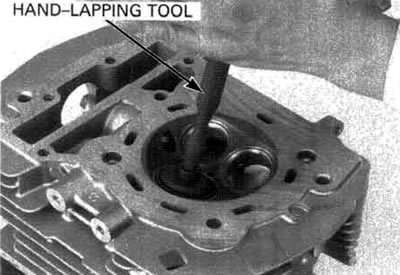

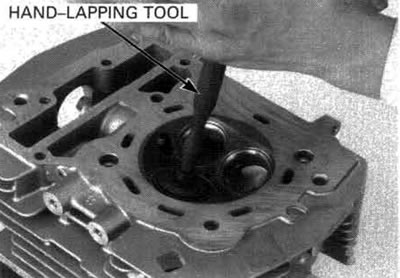

Apply a light coat of Prussian Blue to each valve face. Tap the valve against the valve seat several times using a hand-lapping tool, without rotating the valve, to make a clear pattern.

Remove the valve and inspect the valve seat face (see following page).

The valve cannot be ground. If the valve face is burned or badly worn or if it contacts the seat unevenly, replace the valve.

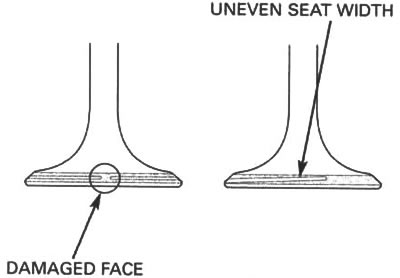

Inspect the valve seat face for:

Damaged face:

- Replace the valve and reface the valve seat.

Uneven seat width:

- Bent or collapsed valve stem;

- Replace the valve and reface the valve seat.

Contact area (too low or too high area):

- Reface the valve seat.

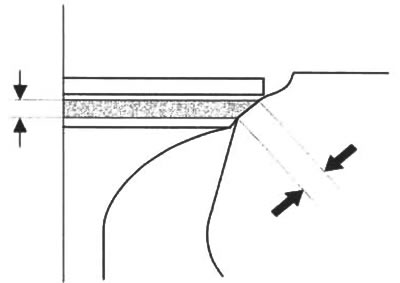

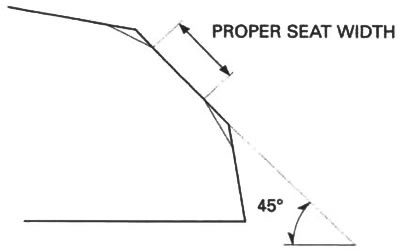

Inspect the width of the valve seat.

The valve seat contact should be within the specified width and even all around the circumference.

Standard:

- IN: 1.10 - 1.30 mm (0.043 - 0.051 in)

- EX: 1.40 - 1.60 mm (0.055 - 0.063 in)

Service limit:

- IN: 1.70 mm (0.669 in)

- EX: 2.00 mm (0.079 in)

If the valve seat width is not within specification, reface the valve seat.

Valve seat refacing

Follow the refacer manufacturer's operating instructions.

Be careful not to grind the seat more than necessary.

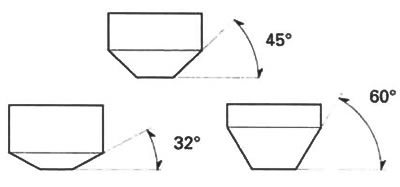

If the contact area is too high on the valve, the seat must be lowered using a 32° flat cutter.

If the contact area is too low on the valve, the seat must be raised using a 60° inner cutter. Refinish the seat to specification, using a 45° finish cutter.

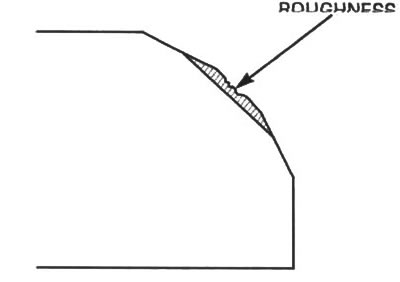

Using a 45° cutter, remove any roughness or irregularities from (tie seat.

Tools:

- Seat cutter, 40 mm (45° IN) — 07780-0010500

- Seat cutter, 46 mm (45° EX) — 07780-0011200

- Cutter holder, 6.6 mm — 07781-0010202 or 07942-ZE2000D (U.S.A, only)

- Cutter holder, 8 mm — 07ZMH-MCH0100 or equivalent commercially available in U.S.A.

Using a 32° cutter, remove 1/4 of the existing valve seat material.

Tools:

- Flat cutter, 38.5 mm (32° IN) — 07780-0012400

- Flat cutter, 50mm (32° EX) — 07780-0013600

- Cutter holder, 6.6 mm — 07781-0010202 or 07942-ZE2000D (U.S.A, only)

- Cutter holder, 8 mm — 07ZMH-MCH0100 or equivalent commercially available in U.S.A.

Using a 60° cutter, remove the bottom 1/4 of the old seat.

Tools:

- Interior cutter, 34 mm (60° IN) — 07780-0014700

- Interior cutter, 45mm (60° EX) — 07780-0014800

- Cutter holder, 6.6 mm — 07781-0010202 or 07942-ZE2000D (U.S.A, only)

- Cutter holder, 8 mm — 07ZMH-MCH0100 or equivalent commercially available in U.S.A.

Using a 45° cutter, cut the seat to the proper width.

Make sure all pitting and irregularities are removed.

Change the angle of the lapping tool frequently to prevent uneven seat wear.

After cutting the seat, apply lapping compound to the valve face, and lap the valve using light pressure.

After lapping, wash any residual compound off the cylinder head and valve.

Recheck the seat contact after lapping.

Lapping compound can cause damage if it enters between the valve stem and guide.