Swingarm Removal

Remove:

- Muffler Body (See Muffler Body Removal in the Engine Top End chapter)

- Engine Sprocket (See Engine Sprocket Removal in the Final Drive chapter)

- Rear Wheel (See Rear Wheel Removal in the Wheels/Tiers chapter)

- Raise the rear wheel off the ground with jack.

Special Tools - Jack: 57001-1238

Jack Attachment: 57001-1608

Remove:

- Right Rear Footpeg Stay (See Rear Shock Absorber Removal)

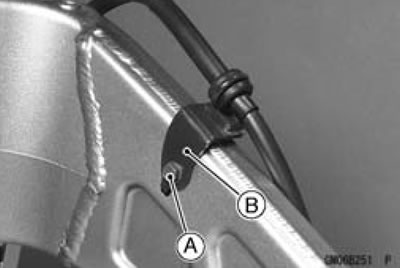

- Bolt [A]

- Brake Hose Clamp [B]

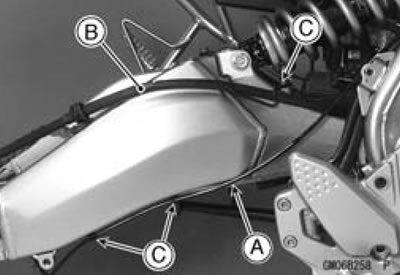

- For models equipped with an ABS, free the rear wheel rotation sensor lead [A] and brake hose [B] from the clamps [C].

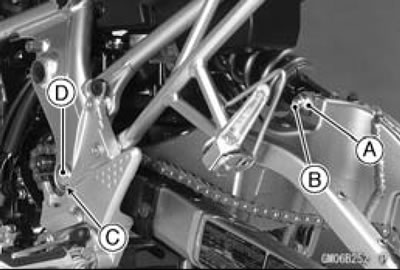

Remove:

- Lower Rear Shock Absorber Nut [A] and Washer

- Lower Rear Shock Absorber Bolt [B]

- Unscrew the swingarm pivot shaft nut [C].

Pull off the pivot shaft [D], and remove the swingarm.

Swingarm Installation

- Installation is the reverse of removal.

Apply grease to the lip of the oil seals.

Be sure to install the oil seals and collar [A] to the swingarm.

- Tighten the pivot shaft nut.

Torque - Swingarm Pivot Shaft Nut: 108 Nm (11.0 kgf·m, 80 ft·lb)

- Install the removed parts (see appropriate chapters).

Swingarm Bearing Removal

Remove:

- Swingarm (See Swingarm Removal)

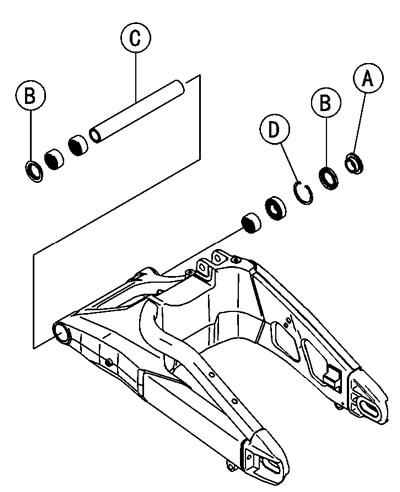

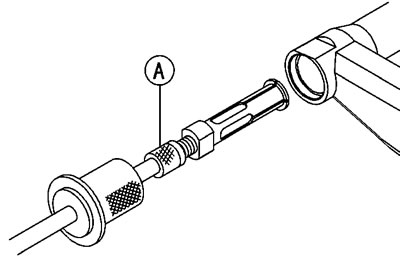

- Collar [A]

- Oil Seals [B]

- Sleeve [C]

- Circlip [D]

Special Tool - Inside Circlip Pliers: 57001-143

- Remove the ball bearing and needle bearings.

Special Tool - Oil Seal & Bearing Remover [A]: 57001-1058

Swingarm Bearing Installation

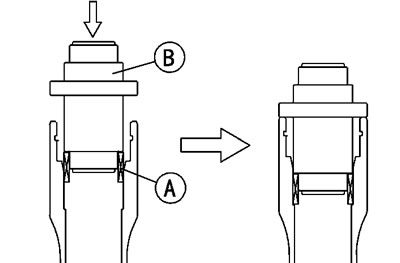

- Replace the ball and needle bearings [A] with new ones.

- Install the ball and needle bearings so that the manufacturer's marks face out.

Special Tools - Bearing Driver Set: 57001-1129

Needle Bearing Driver, 028 [B]: 57001-1610

Spacer, 028: 57001-1663

- Replace the circlip with a new one.

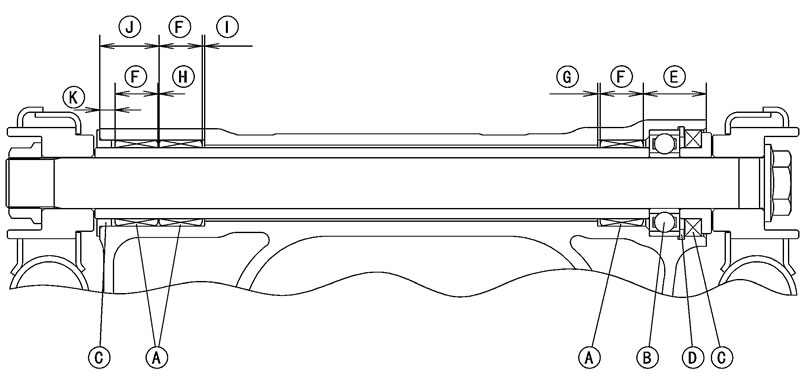

- Install the needle bearings [A], ball bearing [B] and oil seals [C] position as shown.

- Circlip [D]

- 25 mm (0.98 in.) [E]

- 17 mm (0.67 in.) [F]

- 1 mm (0.04 in.) [G]

- 0.5 mm (0.02 in.) [H]

- 1 mm (0.04 in.) [I]

- 23.5 mm (0.93 in.) [J]

- 6 mm (0.24 in.) [K]

Swingarm Bearing, Sleeve Inspection

Caution: Do not remove the bearings for inspection. Removal may damage them.

- Inspect the needle bearings [A] and ball bearing installed in the swingarm.

The rollers and ball in a bearing normally wear very little, and wear is difficult to measure. Instead of measuring, visually inspect the bearing for abrasion, discoloration, or other damage.

If the needle bearing and sleeve show any sings of abnormal wear, discoloration, or damage, replace them as a set.

- Turn the bearing in the swingarm back and forth [A] while checking for plays, roughness, or binding.

If the bearing play, roughness, or binding is found, replace the bearing.

- Examine the bearing seal [B] for tears or leakage.

If the seal is torn or is leaking, replace the bearing.

Swingarm Bearing Lubrication

Note: Since the bearings are packed with grease and sealed, lubrication is not required.

Chain Guide Inspection

- Refer to the Chain Guide Wear Inspection in the Periodic Maintenance chapter.