Removal

Before starting work, ensure the motorcycle is stabilised and adequately supported. This will help prevent it from falling and causing injury to the operator or damage to the motorcycle.

1. Support the motorcycle so that the rear wheel is clear of the ground.

2. Remove the rear wheel as described on page 16.8.

3. Remove the left hand rear suspension unit as described on page 13.4.

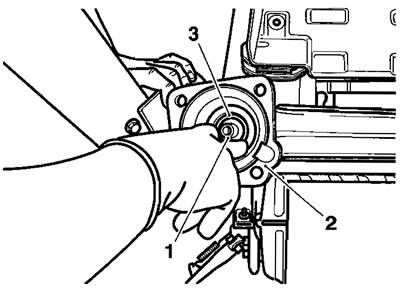

4. Release the four nuts securing the bevel box to the swinging arm.

5. Ease the bevel box towards the rear of the motorcycle, detaching the pinion coupler from the drive shaft.

Installation

Note: Prior to installation, check that the drive shaft is supported by the sleeve inside the swinging arm. Rectify as necessary.

1. Drive shaft; 2. Swinging arm; 3. Sleeve

1. Apply a smear of Molybdenum Disulphide grease to the drive shaft splines and wheel driven flange.

2. Position the bevel box to the drive shaft engaging the pinion coupler and drive shaft at the same time.

Note: Before tightening the bevel box nuts, fully insert the wheel spindle through the swinging arm to ensure it will realign with the swinging arm when the wheel is installed.

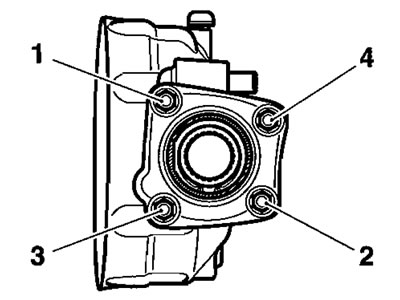

Note: Bevel box to swinging arm fixings are tightened in two stages and in a specific sequence. Tighten all fixings to the lower torque before progressing to the higher figure.

3. Align the bevel box by fully inserting the wheel spindle through the bevel box and swinging arm then, in the order shown below, tighten all the bevel box nuts to 20 Nm, then to 64 Nm.

Bevel box bolt tightening sequence

4. Refit the left hand rear suspension unit as described on page 13.5.

5. Refit the rear wheel as described on page 16.9.

6. Lower the motorcycle to the ground and park it on the side stand.

7. Check and top up the bevel box oil level as described on page 6.3.

Drive shaft

Drive shaft details can be found in the rear suspension section on page 13.5.