Note: Connecting rod bolts are treated with an anti-rust solution which must not be removed. Clean the connecting rod with high flash-point solvent. Remove all bearings and inspect for damage, wear and any signs of deterioration and replace as necessary.

Warning! Connecting rod bolts MUST only be used once. If the bolts are removed or undone for any reason, new bolts MUST always be used. Re-using bolts can cause connecting rods and their caps to detach from the crankshaft causing severe engine damage, loss of motorcycle control and an accident.

Note: Ensure the piston is fitted correctly to the connecting rod. If a previously run engine is being rebuilt, always ensure that the piston and connecting rod are assembled in the same orientation, and to the same cylinder, as prior to strip-down.

1. Fit the piston onto the connecting rod (see Piston - assembly).

2. Fit the three piston and connecting rod assemblies into the barrel and then fit the assembly to the crankcase (see Barrels - installation).

3. Select the big end bearing shells (see Connecting rod big end journal checking, measuring and bearing selection).

4. Fit the bearing shells to the connecting rod and the big end cap, lubricate with a 50/50 solution of engine oil and molybdenum disulphide grease.

5. Align the connecting rod to the crankshaft and fit the big end cap.

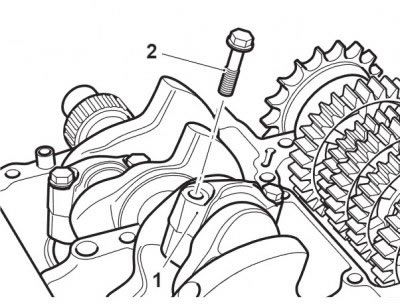

1. Big end cap; 2. Connecting rod bolt

Caution! The torque characteristics of the connecting rod bolts are sensitive to the correct lubrication being applied. If the threads and under head areas are not lubricated with molybdenum disulphide grease, the bolts may be stretched and may become loose when in service resulting in an engine failure.

6. Lubricate the threads and under-head area of the new bolts with molybdenum disulphide grease. Tighten the bolts evenly and progressively as follows:

Caution! The torque characteristics of the connecting rod bolts are sensitive to the rate at which they are tightened. If all the torque is applied in one action, the bolt may be stretched and may become loose when in service resulting in an engine failure.

- Tighten to 14 Nm.

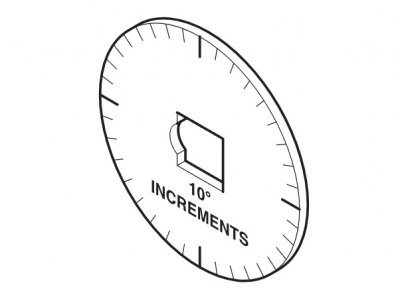

- Tighten through 210° of bolt rotation as measured using T3880105 - Torque Angle Gauge.

T3880105 - Torque Angle Gauge

Perform the following operations: