1. Use high flash-point solvent to clean the crankcase mating faces. Wipe the surfaces clean with a lint-free cloth.

2. Ensure that the transmission is in neutral.

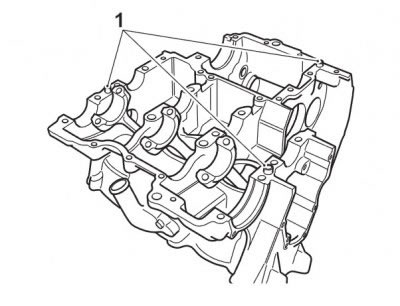

3. Ensure that the three locating dowels are in position in the upper crankcase.

1. Locating dowels

4. Apply a thin bead of silicone sealant (at the factory, ThreeBond 1216E is used) to the lower crankcase mating faces.

Sealer areas

Caution! Do not use excessive amounts of sealer. The extra sealer may become dislodged and could block the oil passages in the crankcases causing severe engine damage.

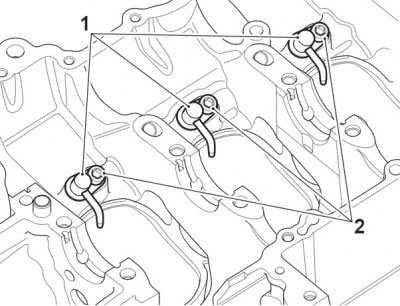

5. If removed, refit the three piston cooling jets into the upper crankcase and tighten their fixings to 10 Nm.

1. Piston cooling jets; 2. Fixings

Caution! Ensure the three piston cooling jets are installed. If the piston cooling jets are omitted, oil pressure will be reduced. Running the engine with low oil pressure will cause severe engine damage.

6. Install and lubricate the crankshaft bearing shells with a 50/50 solution of engine oil and molybdenum disulphide grease (see Connecting rod big end journal checking, measuring and bearing selection before proceeding).

7. Lubricate the crankshaft journals with clean engine oil.

8. Fit the crankshaft (see Crankshaft - installation).

9. If removed, refit the balancer (see Balancer - installation).

10. Position the lower crankcase to the upper. An assistant may be required to support the crankcase during alignment.

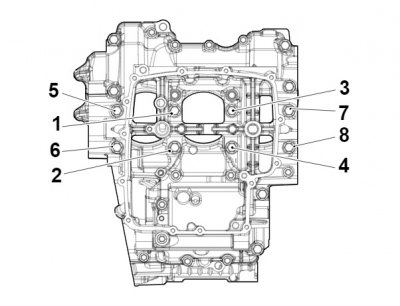

11. Fit the bolts into the lower crankcase and hand tighten until the bolt heads are near contact with the crankcase. Note the position of the hardened washers under bolts 1 to 8.

Note: The crankcase screws are tightened in stages. Two different sizes of crankcase bolts are used. All bolts must be tightened in the two stages as follows:

Caution! Failure to follow the correct bolt tightening sequence may result in permanent crankcase damage.

Stage 1

1. In the sequence shown below, tighten only the M8 size crankcase bolts (number 9 to 26) to 12 Nm.

Crankcase bolt 9 to 26 tightening sequence

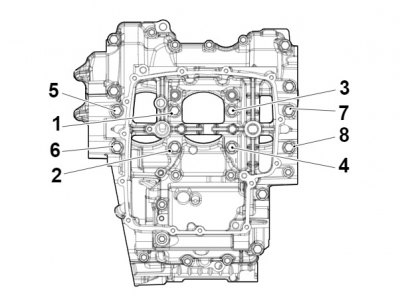

Stage 2

1. In the sequence shown below, tighten the new crankcase bolts 1 to 8 to 10 Nm.

Crankcase bolt 1 to 8 tightening sequence

Stage 3

1. In the sequence shown below, tighten the crankcase bolts 1 to 8 to 100° of bolt rotation using the T3880105 - Torque Angle Gauge:

Crankcase bolt 1 to 8 tightening sequence

T3880105 - torque angle gauge

Perform the following operations:

- Rotate the crankshaft clockwise. Check for tight spots and rectify as necessary.

- Oil pump - installation

- Sump - installation

- Camshaft drive chain tensioner - installation

- Camshaft cover - installation

- Clutch - installation

- Alternator rotor - installation

- Engine - installation