Removal

Mark the position of the original semi-bushings on the crankcase.

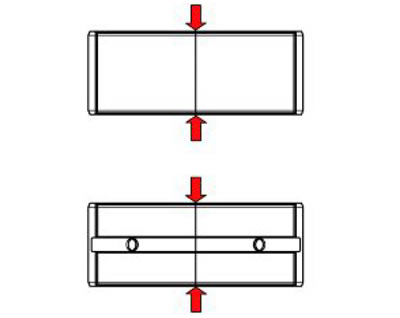

To reduce the installation force necessary, score an incision approximately 0.5 mm (0.02 in) deep (without cutting into the steel shell) in each semi-bushing in the area indicated in the figure.

Remove the bushings with the crankcase cold, using a press and the specific tool and pushing inward from the outside of the crankcase.

- Specific tooling: 020726Y Extractor for bushings

Installing

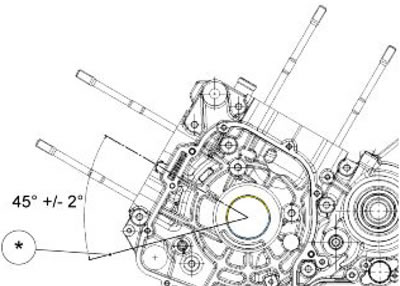

The orientation of the semi-bushings must match the specifications indicated in the drawing as closely as possible.

Key: * Semi-bushing joint line

Note. When replacing the semi-bushings alone, the new components must be the same colour as the removed components. If the colour of the old components is no longer visible, use the table to identify the correct components, referring to the crankcase and crankshaft classes.

Fit the new bushings with the crankcase cold, using a press and the specific tool and pushing outward from the inside of the crankcase, until the punch comes into contact with the crankcase surface.

- Specific tooling: 020727Y Punch for bushings

Assembling the connecting rod

Caution! To fit the connecting rods, check the coupling types indicated in the "Crankcase - crankshaft connecting rod" section, in the "Characteristics" chapter of the workshop manual.