Bearings and oil seal check

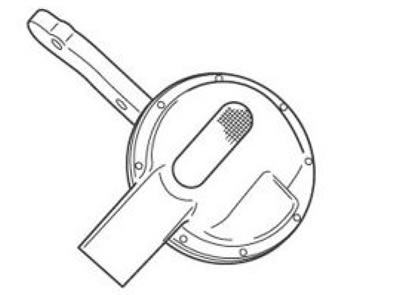

Thoroughly clean the two sections of the crankcase, the ball bearings, the threads of the crankcase fixing screws and the bearing seats with a non-aggressive solvent. Clean the seal surfaces and check that they are not damaged.

Caution! To avoid damaging both crankcase halves place them on a flat surface.

Check that both crankcase halves are not cracked or damaged.

Check that all threads are in proper conditions.

Check that all oil seals remaining in their position are not worn or damaged.

Check all ball bearings for clearance, smoothness and potential distortions.

Caution! Lubricate ball bearings with engine oil before further checking.

If the internal ring does not rotate smoothly and silently or if there is some noise while it turns, it means that the bearing is faulty and must be replaced.

Oil filter and oil delivery pipe check

Check the oil filter for damage. If necessary, replace the part.

Clean the oil net with petrol and inspect the net links for potential damage.

Caution! Check the engine oil filter O-ring.

Lubrication check

Working on both crankcase halves, remove and thoroughly clean the nozzle that lubricates the piston crown.

Replace the spray nozzle O-ring if necessary.

Replace the O-ring on the oil passage duct.

Before refitting

Upon refitting the crankshaft, grease the shaft bushing-connecting rod coupling.